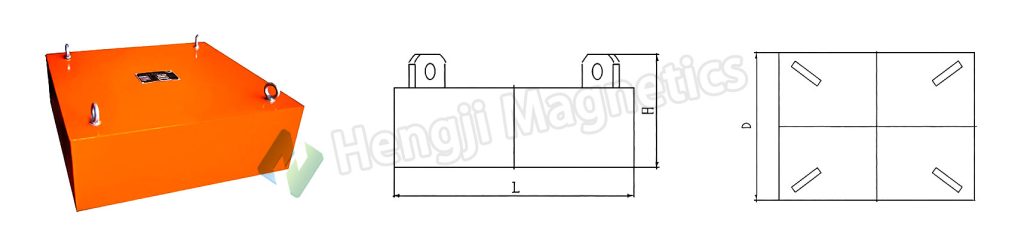

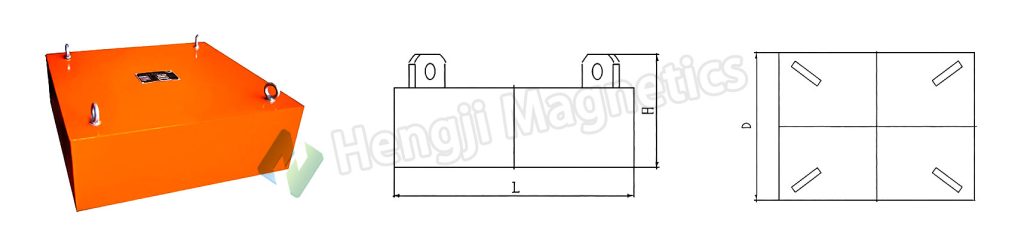

RCYB Suspended Permanent Overhead Magnetic Separator Product Overview

The RCYB series suspended permanent magnetic separator provides a reliable and efficient solution for extracting ferrous contaminants from various non-magnetic materials. Utilizing high-performance rare-earth magnets, this permanent suspension magnet delivers exceptional separation capability without electrical power consumption, featuring deep magnetic penetration and maintenance-free operation.

This versatile cross belt magnet offers simple installation and robust construction, effectively removing ferrous objects weighing from 0.1 to 35 kilograms. The permanent magnetic system maintains stable performance for over 10 years, with all technical specifications complying with JB/T8711-2006 standards, ensuring long-term reliability across diverse industrial applications where consistent ferrous separation is required.

RCYB Suspended Permanent Overhead Magnetic Separator Key Features

High-Performance Magnetic System

Utilizing premium NdFeB permanent magnets, this permanent suspension magnet delivers exceptional magnetic strength exceeding 1200 Gauss. The optimized magnetic circuit ensures deep penetration capability, making this cross belt magnet suitable for material layers up to 300mm thick, with consistent performance across various operating conditions.

Robust and Simple Structure

Featuring a compact, lightweight design, this permanent suspension magnet requires no electrical connections for truly maintenance-free operation. The fully sealed construction with high protection rating ensures reliable performance of this cross belt magnet in outdoor environments, while wear-resistant materials extend equipment lifespan significantly.

Economic Efficiency

With zero energy consumption during operation, this permanent suspension magnet offers substantial cost savings. The one-time investment in this cross belt magnet delivers long-term benefits through minimal maintenance requirements and rapid investment recovery, requiring only periodic cleaning to maintain optimal performance.

Environmental Safety

Operating without electromagnetic radiation or noise generation, this permanent suspension magnet ensures complete safety for both personnel and environment. The eco-friendly cross belt magnet complies with international energy conservation standards, contributing to sustainable production practices while maintaining superior separation efficiency.

RCYB Suspended Permanent Overhead Magnetic Separator Working Principle

The RCYB permanent suspension magnet operates through efficient magnetic attraction principles, providing reliable ferrous separation without electrical power requirements. This robust cross belt magnet delivers consistent performance through its carefully engineered operational process.

Magnetic Field Generation

High-performance permanent magnets create a stable, powerful magnetic field within this permanent suspension magnet. The magnetic flux effectively penetrates material layers to establish a comprehensive separation zone, enabling this cross belt magnet to maintain consistent performance across various operating conditions.

Ferrous Contaminant Capture

As bulk materials transport beneath the unit, this permanent suspension magnet efficiently extracts ferrous contaminants from the material stream. The captured materials remain securely held against the magnet surface until removal, while non-magnetic materials continue unaffected along the conveyor path. This cross belt magnet ensures reliable protection for downstream equipment through continuous ferrous extraction.

Cleaning Process

The cleaning procedure for this permanent suspension magnet involves periodic manual intervention using appropriate non-magnetic tools or protective equipment. Following quick and straightforward cleaning, the cross belt magnet immediately resumes normal operation, ensuring minimal disruption to production processes while maintaining optimal separation efficiency.

RCYB Suspended Permanent Overhead Magnetic Separator Product Parameters

|

Model

|

Applicable Belt Width (mm)

|

Rated Lifting Height (mm)

|

Magnetic Field Intensity (mT)

|

Material Thickness (≤mm)

|

Applicable Belt Speed (≤m/s)

|

Weight (kg)

|

Overall Dimensions (mm)

|

|

|

|

|

|

|

|

|

L

|

D

|

H

|

|

RCYB-4

|

400

|

125

|

70

|

60

|

4.5

|

105

|

400

|

300

|

220

|

|

RCYB-4-1

|

400

|

75

|

70

|

30

|

|

65

|

400

|

250

|

150

|

|

RCYB-5

|

500

|

150

|

70

|

90

|

|

198

|

500

|

350

|

260

|

|

RCYB-5-1

|

500

|

100

|

70

|

50

|

|

96

|

500

|

280

|

180

|

|

RCYB-6

|

600

|

175

|

70

|

120

|

|

295

|

600

|

450

|

280

|

|

RCYB-6-1

|

600

|

130

|

70

|

60

|

|

158

|

600

|

360

|

180

|

|

RCYB-6.5

|

650

|

200

|

70

|

150

|

|

380

|

650

|

600

|

300

|

|

RCYB-6.5-1

|

650

|

175

|

70

|

100

|

|

310

|

650

|

600

|

110

|

|

RCYB-8

|

800

|

250

|

70

|

200

|

|

550

|

900

|

800

|

360

|

RCYB Suspended Permanent Overhead Magnetic Separator Applications

Conveyor System Integration

The permanent suspension magnet integrates seamlessly with belt conveyor protection systems and vibrating conveyors. This versatile cross belt magnet also serves electromagnetic vibrating feeders and discharge chutes, providing comprehensive iron removal solutions across various conveyance methods.

Industry Applications

In power generation, the permanent suspension magnet ensures coal purity, while mining operations utilize this cross belt magnet for ore processing. The equipment serves metallurgical raw material purification, building materials handling, chemical industry iron removal, and food processing equipment protection, demonstrating exceptional cross-industry adaptability.

Suitable Working Conditions

The permanent suspension magnet performs optimally in applications with low iron content and continuous operation requirements. This compact cross belt magnet is particularly effective for medium to small processing capacities and space-constrained installations, offering reliable performance where larger separation systems would be impractical while maintaining zero energy consumption.

RCYB Suspended Permanent Overhead Magnetic Separator Services

Technical Consultation

We provide comprehensive product selection support for the permanent suspension magnet, including installation position optimization and performance evaluation. Our experts analyze your specific requirements to ensure the cross belt magnet delivers optimal results in your application.

Installation Guidance

Detailed installation manuals cover all critical aspects of the permanent suspension magnet setup. We provide essential installation considerations and commissioning methods to ensure your cross belt magnet operates at peak efficiency from initial operation.

Operation Training

Our training programs cover the principles and structure of both the permanent suspension magnet and cross belt magnet. We demonstrate proper usage techniques while emphasizing crucial safety precautions to ensure efficient and secure operation.

After-Sales Support

We stand behind our products with strong quality guarantees for the permanent suspension magnet. Our technical hotline provides immediate assistance, while dedicated support teams ensure prompt resolution of any operational issues with your cross belt magnet, maintaining your productivity and satisfaction.

Categories

Categories