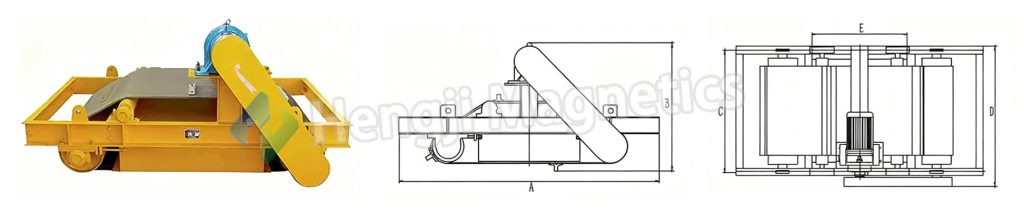

RCYDII Belt Type Conveyor Magnetic Separator Product Overview

The RCYDII series from Weifang Hengji Electromagnetic Machinery Co., Ltd. embodies the latest evolution in permanent magnet separation technology. This advanced belt type magnetic separator employs high-performance NdFeB rare-earth magnets to generate powerful magnetic fields without electrical power, delivering exceptional energy efficiency and significantly reduced operational costs.

Featuring a permanent magnet core and an integrated self-cleaning mechanism, this robust belt conveyor magnetic separator performs effectively with thick material layers across diverse industries like power generation, mining, and building materials. Its maintenance-free magnetic system and durable construction make this belt type magnetic separator an ideal, cost-effective solution for sustainable separation operations requiring reliable performance.

RCYDII Belt Type Conveyor Magnetic Separator Key Features

Exceptional Magnetic Performance

Utilizing high-grade NdFeB permanent magnets, this advanced belt type magnetic separator delivers powerful magnetic fields with deep penetration capability. The computer-optimized magnetic circuit ensures proper field gradient distribution, achieving surface magnetic flux density of 1200-1500mT. This robust belt conveyor magnetic separator effectively handles material layers up to 550mm thick, providing reliable ferrous contamination removal.

Efficient Automatic Cleaning System

The cycloidal reducer driven mechanism ensures smooth, quiet operation, while wear-resistant scraper blades guarantee complete contaminant removal. This belt type magnetic separator features operational adjustments for belt tension and tracking via accessible bearing regulation devices, maintaining optimal performance in continuous operation.

Robust Structural Design

Featuring a compact configuration that simplifies installation and maintenance, this belt conveyor magnetic separator utilizes premium steel components for long-term durability. With IP54 protection rating, the equipment performs reliably in outdoor and challenging industrial environments.

Eco-Friendly Operation

The permanent magnet operation eliminates electricity consumption, making this belt type magnetic separator both energy-efficient and cost-effective. With no heat generation and compliance with international energy conservation standards, this belt conveyor magnetic separator ensures safe, sustainable performance.

RCYDII Belt Type Conveyor Magnetic Separator Working Principle

The RCYDII belt type magnetic separator operates through an efficient combination of permanent magnetic attraction and automated mechanical conveyance systems, delivering reliable ferrous separation without electrical power consumption.

Magnetic Separation Process

High-performance NdFeB permanent magnets generate consistently powerful magnetic fields across the entire working width. As materials transport along the conveyor line, this robust belt conveyor magnetic separator effectively extracts ferrous contaminants from the material flow, securely holding them against the cleaning belt surface. The permanent magnetic system ensures continuous operation with zero energy consumption, making this belt type magnetic separator both economically and environmentally advantageous.

Automatic Cleaning Operation

A cycloidal reducer motor drives continuous cleaning belt movement at optimized speeds. As the belt carries captured ferrous materials beyond the magnetic zone, strategically positioned scraper blades efficiently displace contaminants from the belt surface. The released metals then fall by gravity into designated collection containers, completing the automated cleaning cycle of this advanced belt conveyor magnetic separator without requiring manual intervention or process interruption.

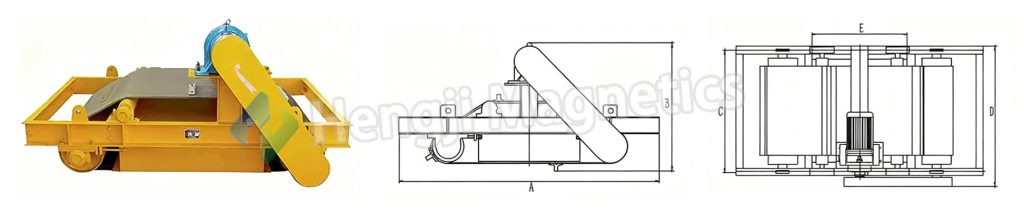

RCYDII Belt Type Conveyor Magnetic Separator Product Parameters

|

Model

|

Applicable Belt Width (mm)

|

Rated Lifting Height (mm)

|

Magnetic Field Intensity (mT)

|

Max. Material Thickness (≤mm)

|

Max. Driving Power (≤kw)

|

Max. Applicable Belt Speed (≤m/s)

|

Weight (kg)

|

Overall Dimensions (mm)

|

|

|

|

|

|

|

|

|

|

A

|

B

|

C

|

D

|

E

|

|

RCYDII-5

|

500

|

150

|

70

|

80

|

1.5

|

|

780

|

1550

|

850

|

755

|

877

|

600

|

|

RCYDII-6

|

600

|

175

|

70

|

125

|

1.5

|

|

920

|

1700

|

895

|

835

|

955

|

690

|

|

RCYDII-6.5

|

650

|

200

|

70

|

150

|

1.5

|

|

1060

|

1750

|

895

|

888

|

1027

|

700

|

|

RCYDII-8

|

800

|

250

|

70

|

200

|

2.2

|

|

1320

|

1940

|

941

|

1088

|

1227

|

800

|

|

RCYDII-10

|

1000

|

300

|

70

|

250

|

3

|

4.5m/s

|

2080

|

2170

|

1050

|

1335

|

1476

|

1100

|

|

RCYDII-12

|

1200

|

350

|

70

|

300

|

4

|

|

2950

|

2450

|

1120

|

1515

|

1664

|

1190

|

|

RCYDII-14

|

1400

|

400

|

70

|

350

|

4

|

|

3821

|

2740

|

1140

|

1755

|

1930

|

1500

|

|

RCYDII-16

|

1600

|

450

|

70

|

400

|

5.5

|

|

5200

|

2850

|

1215

|

1815

|

1961

|

1750

|

|

RCYDII-18

|

1800

|

500

|

70

|

450

|

5.5

|

|

8150

|

3380

|

1290

|

2025

|

2167

|

1980

|

RCYDII Belt Type Conveyor Magnetic Separator Applications

Power Generation Industry

The belt type magnetic separator efficiently processes coal in thermal power plants, while also serving biomass power facilities for fuel pre-treatment. These reliable belt conveyor magnetic separator units protect downstream equipment from ferrous damage in continuous energy production operations.

Mining and Metallurgy

In iron ore processing plants, the belt type magnetic separator provides essential raw material purification. The equipment also delivers crucial crusher protection in non-ferrous metal mining operations, where the robust belt conveyor magnetic separator prevents machinery damage from tramp iron.

Building Materials and Chemicals

Cement plants utilize the belt type magnetic separator in raw material preparation systems to remove ferrous contaminants. For glass manufacturing, the precision belt conveyor magnetic separator purifies quartz sand, ensuring final product quality in both building material and chemical processing applications.

Additional Sectors

The versatile belt type magnetic separator serves waste processing facilities for material sorting operations, while food processing plants employ the sanitary belt conveyor magnetic separator for metal contamination control, demonstrating the equipment’s adaptability across diverse industrial requirements.

RCYDII Belt Type Conveyor Magnetic Separator Services

Installation and Commissioning

We provide professional guidance for proper installation of your belt type magnetic separator, ensuring correct positioning and alignment. Our technicians offer on-site support to adjust operating parameters, guaranteeing optimal performance of your belt conveyor magnetic separator from initial startup.

Technical Training

Comprehensive training programs cover operational procedures, safety protocols, and troubleshooting techniques for both belt type magnetic separator and belt conveyor magnetic separator equipment. We educate your team on proper maintenance schedules and best practices to maximize equipment lifespan and efficiency.

After-Sales Support

Our ongoing support includes wear parts identification and replacement guidance specific to your belt type magnetic separator configuration. We provide 24/7 technical consultation services and conduct regular equipment inspections to evaluate the performance of your belt conveyor magnetic separator, ensuring continuous operational reliability.

Preventive Maintenance

Scheduled maintenance services include magnetic strength verification, belt tension adjustment, and component lubrication for your belt type magnetic separator. These proactive measures help maintain peak efficiency and extend the service life of your belt conveyor magnetic separator systems.

Categories

Categories