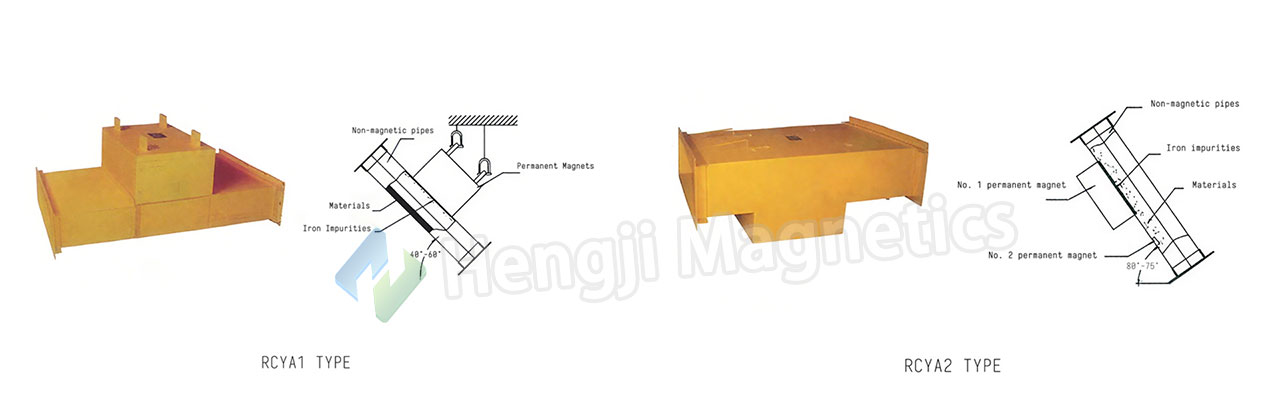

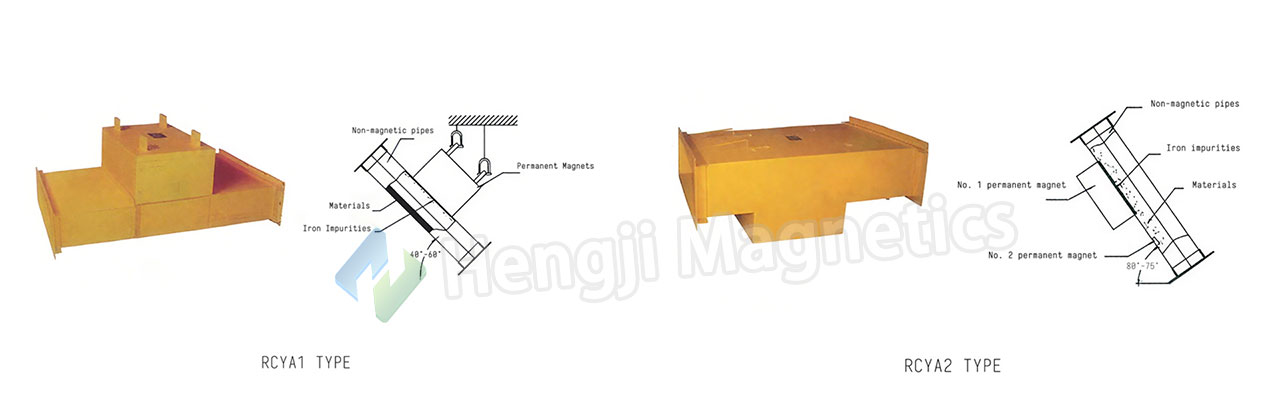

RCYA Hump Magnetic Material Separator Product Overview

The RCYA Series Pipeline Permanent Magnetic Separator provides an efficient solution for removing ferrous impurities from powdered, granular, and slurry materials. This ISO9001-certified magnetic material separator features a compact and robust design for easy installation and reliable operation in pipeline systems.

Engineered for direct in-line integration, this versatile pipeline magnetic separator enables continuous automated iron removal across food processing, plastics, chemicals, pharmaceuticals, and ceramics industries. The equipment effectively captures tramp iron to protect downstream machinery and enhance product purity. As a specialized magnetic material separator, it operates seamlessly within closed-pipeline systems, delivering clean and efficient purification for various industrial applications.

RCYA Hump Magnetic Material Separator Key Features

High-Efficiency Magnetic Circuit

This hump magnetic separator utilizes a sophisticated circuit with high-performance NdFeB magnets, delivering an intense magnetic field that effectively captures fine and embedded ferrous contaminants. This reliable magnetic material separator ensures consistent performance through its advanced magnetic design.

Fully Enclosed Structure

Constructed from premium SUS316L stainless steel with standard flanges, this hump magnetic separator provides exceptional sealing integrity. The enclosed design of this magnetic material separator prevents leakage and dust emission, making it ideal for hygienic production environments.

Zero Energy Consumption & Multi-Layer Filtration

Operating on permanent magnet technology, this hump magnetic separator requires no electrical power. The unique grid-like magnetic rod arrangement in this magnetic material separator enables multi-stage purification for thorough ferrous particle removal.

Environmental Adaptability & Maintenance

Suitable for altitudes up to 3000 meters and temperatures from -20°C to +40°C, this hump magnetic separator offers strong adaptability. The simple mechanical structure of this magnetic material separator ensures easy maintenance through periodic manual cleaning of accumulated ferrous debris.

RCYA Hump Magnetic Material Separator Working Principle

The RCYA hump magnetic separator operates on permanent magnetic adsorption principles, providing efficient iron removal in pipeline systems. This reliable magnetic material separator is installed directly within material pipelines using its flanged connections for seamless integration.

Magnetic Separation Process

As material flows through the unit, the powerful magnetic field generated by Neodymium magnetic rods instantly captures ferromagnetic impurities. The hump magnetic separator firmly holds contaminants against the housing’s inner wall while allowing cleansed material to continue unimpeded through the pipeline, making this magnetic material separator ideal for continuous processing applications.

Maintenance & Durability

Accumulated iron contaminants are removed during planned maintenance shutdowns using simple manual methods. Each magnetic rod in this hump magnetic separator is hermetically sealed within seamless stainless steel tubes, preventing material contact and ensuring long-term performance. This robust construction establishes the RCYA as a dependable magnetic material separator for demanding industrial applications.

RCYA Hump Magnetic Material Separator Product Parameters

|

Model

|

Applicable Capacity (T/h)

|

Duct Dimensions (L×W×H, mm)

|

Permanent Magnet Dimensions (L×W×H, mm)

|

Flange Interface Dimensions (L×W, mm)

|

Applicable Angle with Ground

|

Weight (kg)

|

Applicable Materials

|

|

RCYA1-15

|

15

|

800×600×150

|

500×300×220

|

600×220

|

|

190

|

Small lumps

|

|

RCYA1-30

|

30

|

950×600×170

|

600×400×240

|

700×230

|

|

240

|

|

RCYA1-50

|

50

|

1000×700×180

|

700×500×240

|

800×280

|

|

405

|

|

RCYA1-80

|

80

|

1100×750×200

|

800×550×240

|

900×300

|

40° – 50°

|

790

|

|

RCYA1-100

|

100

|

1200×900×240

|

900×700×300

|

1000×320

|

|

1050

|

|

RCYA1-150

|

150

|

1300×1000×240

|

1150×650×320

|

1100×350

|

|

1280

|

|

RCYA1-200

|

200

|

1400×1100×260

|

1350×800×340

|

1300×380

|

|

1650

|

|

RCYA1-300

|

300

|

1600×1400×320

|

1550×1200×380

|

1500×400

|

|

2200

|

RCYA2

|

Model

|

Applicable Capacity (T/h)

|

Duct Dimensions (L×W×H, mm)

|

Permanent Magnet Dimensions (L×W×H, mm)

|

Flange Interface Dimensions (L×W, mm)

|

Applicable Angle with Ground

|

Weight (kg)

|

Applicable Materials

|

|

RCYA2-15

|

15

|

800×500×200

|

500×300×120(1)

500×70×30(2)

|

600×300

|

|

170

|

Powdery

|

|

RCYA2-30

|

30

|

900×600×250

|

600×400×140(1)

800×70×30(2)

|

700×350

|

|

260

|

|

RCYA2-50

|

50

|

1000×700×300

|

700×400×180(1)

700×70×30(2)

|

800×400

|

55° – 75°

|

300

|

|

RCYA2-80

|

80

|

1100×800×300

|

800×500×200(1)

900×70×30(2)

|

900×400

|

|

710

|

|

RCYA2-100

|

100

|

1200×900×300

|

900×600×300(1)

900×70×30(2)

|

1000×400

|

|

950

|

|

RCYA2-120

|

120

|

1200×1000×300

|

1000×700×300(1)

900×70×30(2)

|

1100×400

|

|

1100

|

|

RCYA2-200

|

200

|

1200×1200×350

|

1200×900×350(1)

1200×70×30(2)

|

1300×450

|

|

1350

|

RCYA Hump Magnetic Material Separator Applications

Food and Pharmaceutical Industries

The hump magnetic separator ensures product safety by removing ferrous contaminants from flour, starch, and pharmaceutical powders. This reliable magnetic material separator meets stringent GMP and hygiene standards for sensitive production environments.

Chemical and Plastics Industries

Effectively protecting processing machinery, the hump magnetic separator removes iron particles from pigments, dyes, and plastic pellets. This versatile magnetic material separator maintains color integrity and product quality in chemical and plastic manufacturing.

Ceramics and Building Materials

The hump magnetic separator purifies kaolin, quartz sand, and cement additives by eliminating iron impurities. This efficient magnetic material separator prevents discoloration in ceramics and enhances performance characteristics of building materials.

Environmental and Recycling

Supporting circular economy initiatives, the hump magnetic separator recovers ferrous metals from waste streams. This durable magnetic material separator increases material purity and value in recycling operations across various sectors.

RCYA Hump Magnetic Material Separator Services

Customized Engineering Solutions

We provide tailored hump magnetic separator designs based on your specific pipeline dimensions and material characteristics. Our customized magnetic material separator solutions ensure optimal performance and seamless integration into your production line.

Professional Installation Guidance

Detailed installation diagrams and technical specifications guarantee proper setup of your hump magnetic separator. We ensure correct flange connections and equipment securing for safe operation of your magnetic material separator system.

Comprehensive Operational Training

Our training covers critical safety protocols including magnetic field precautions and standardized cleaning procedures. We ensure safe operation of your hump magnetic separator while maximizing the efficiency of your magnetic material separator system.

Responsive After-Sales Support

A dedicated service hotline provides immediate technical support for your hump magnetic separator. Our rapid response ensures consistent uptime and reliable performance of your magnetic material separator.

Proactive Maintenance Guidance

We help establish periodic cleaning schedules to prevent magnetic saturation in your hump magnetic separator. Proper maintenance ensures long-term reliability and optimal performance of your magnetic material separator investment.

Categories

Categories