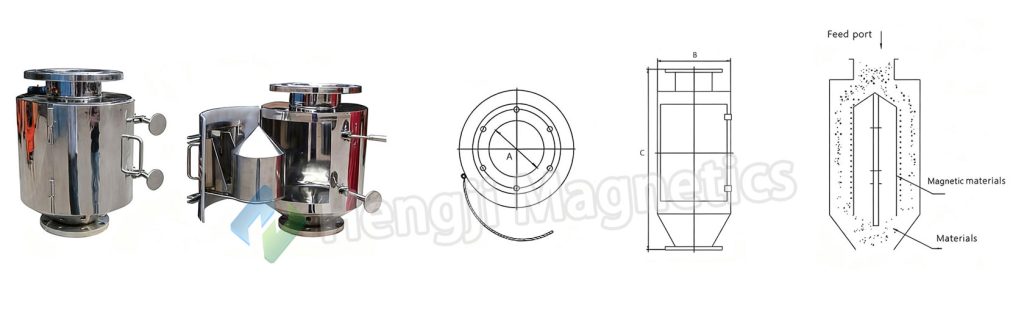

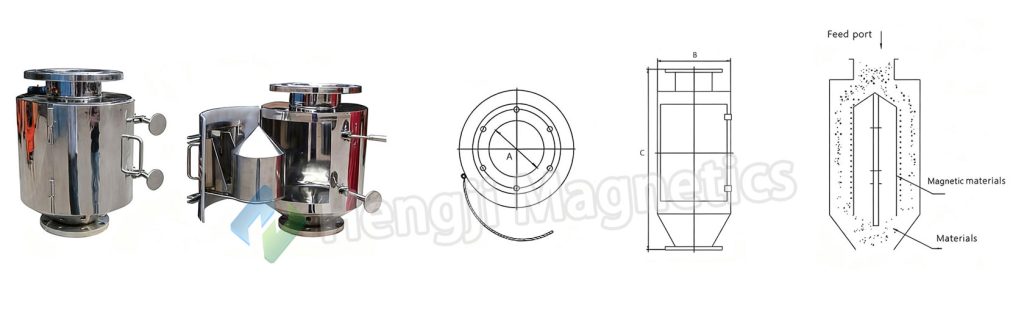

RCYZ Bullet Magnet Particle Separator Product Overview

The RCYZ Series Pipeline Self-Cleaning Magnetic Separator represents advanced automated separation technology for purifying powdery and granular materials in enclosed pipelines. This high-performance magnetic particle separator efficiently removes ferrous impurities, revolutionizing traditional iron removal methods through continuous automated operation.

Designed as a specialized bullet magnet system, it integrates directly into material flow lines to eliminate manual interventions. The equipment’s core philosophy emphasizes high efficiency, energy conservation, and unmanned operation, making this magnetic particle separator indispensable for modern automated production lines. By protecting downstream processing equipment from ferrous damage, this reliable bullet magnet solution ensures both operational integrity and superior product quality across various industrial applications.

RCYZ Bullet Magnet Particle Separator Key Features & Performance

High-Efficiency Magnetic System

This advanced bullet magnet utilizes high-performance NdFeB magnets with multi-pole magnetic circuits, delivering powerful magnetic fields with deep penetration. The rotating magnetic assembly in this magnetic particle separator ensures exceptional capture of fine iron contaminants, outperforming conventional equipment.

Fully Automatic Operation

Featuring continuous self-cleaning capability, this bullet magnet automatically transports captured ferrous materials to concealed discharge ports. The automated process of this magnetic particle separator eliminates manual cleaning, reducing labor costs while ensuring production line automation.

Easy Installation & Energy Efficiency

Simple flange connection enables direct pipeline integration for this bullet magnet. The permanent magnet design of this magnetic particle separator requires zero energy for magnetic functions, with only intermittent power needed for cleaning mechanisms.

Durable Construction & Temperature Options

With fully sealed magnetic systems and wear-resistant components, this bullet magnet ensures long-term reliability. The magnetic particle separator offers standard (≤45°C) and high-temperature models (up to 150°C) to meet various industrial requirements.

RCYZ Bullet Magnet Particle Separator Working Principle

The RCYZ bullet magnet operates through an integrated system of magnetic adsorption and mechanical conveyance. Installed at a 55-degree angle in material pipelines, this advanced magnetic particle separator performs two synchronized processes during material flow.

Contaminant Capture Process

As material flows through the inclined pipeline, the powerful magnetic field of this bullet magnet instantly captures ferrous contaminants. The magnetic particle separator holds impurities against its internal magnetic assembly while clean material continues unimpeded through the system.

Automatic Discharge Cycle

The rotating magnetic assembly transports captured ferrous materials to a concealed discharge outlet. When reaching the separation point, the bullet magnet releases contaminants through gravity while maintaining product stream integrity. The magnetic particle separator incorporates negative pressure connections for dust control, ensuring clean operation throughout the automated discharge process.

RCYZ Bullet Magnet Particle Separator Product Parameters

|

Model

|

Applicable Capacity (T/h)

|

Magnetic Field Intensity (GS)

|

Max. Feed Particle Size (<mm)

|

Overall Dimensions (mm)

|

|

|

|

|

|

A

|

B

|

C

|

|

RCYZ-5

|

5

|

2000 – 16000

|

3.0

|

219

|

300

|

600

|

|

RCYZ-10

|

10

|

2000 – 16000

|

3.0

|

245

|

330

|

800

|

|

RCYZ-20

|

20

|

2000 – 16000

|

4.0

|

273

|

360

|

900

|

|

RCYZ-30

|

30

|

2000 – 16000

|

4.0

|

325

|

415

|

1000

|

|

RCYZ-50

|

50

|

2000 – 16000

|

5.0

|

377

|

470

|

1100

|

|

RCYZ-60

|

60

|

2000 – 16000

|

6.0

|

450

|

540

|

1300

|

|

RCYZ-100

|

100

|

2000 – 16000

|

8.0

|

530

|

630

|

1500

|

RCYZ Bullet Magnet Particle Separator Industry Applications

The RCYZ bullet magnet serves multiple industries requiring efficient iron removal from dry powders and fine granules, providing reliable protection and quality enhancement.

Core Industrial Applications

In building materials and cement production, this magnetic particle separator protects grinding equipment and improves product quality by removing tramp iron from raw materials. The chemical and plastics industries utilize this bullet magnet to ensure product purity and color consistency in various raw materials.

Specialized Sectors

Food and pharmaceutical operations rely on this magnetic particle separator for safety-critical applications, with food-grade models available for high-hygiene requirements. The ceramics industry depends on this bullet magnet to prevent defects and enhance product whiteness by purifying raw materials.

Extended Applications

Metallurgy and mining operations benefit from this magnetic particle separator for mineral purification, while grain and feed processing facilities use the bullet magnet to protect machinery and enhance final product quality across diverse processing environments.

RCYZ Bullet Magnet Particle Separator Services and Support

Professional Selection & Support

We provide expert consultation to select the optimal bullet magnet configuration based on your material characteristics and separation requirements. Our technical team ensures the magnetic particle separator meets your specific operational needs.

Customization Services

Tailored solutions include custom pipeline diameters, installation angles, and specialized materials. We adapt the bullet magnet design to your unique requirements, including food-grade and high-temperature versions of the magnetic particle separator.

Installation & Commissioning

Detailed installation manuals and on-site engineering support ensure proper setup of your bullet magnet system. We guarantee optimal performance of your magnetic particle separator from initial commissioning.

After-Sales Guarantee

Comprehensive warranty coverage and responsive spare parts supply maintain your bullet magnet operation. Our technical support ensures continuous performance of your magnetic particle separator system.

Continuous Improvement

We regularly enhance our bullet magnet products based on technological advancements and customer feedback, keeping your magnetic particle separator system updated with the latest innovations.

Categories

Categories