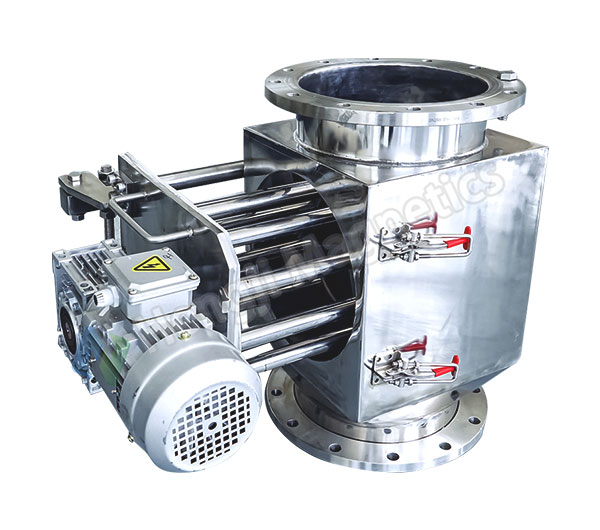

CQZ Drawer Magnets & Magnetic Grate Separator Product Overview

The CQZ series represents a significant advancement in magnetic separation technology, combining fully automated pneumatic control with high-performance rare-earth magnetic systems. These sophisticated drawer magnets are engineered for extracting ferrous contaminants from powdered materials across food processing, plastics, chemicals, pharmaceuticals, and ceramics industries.

Utilizing neodymium iron boron rare-earth alloys, these powerful magnetic grate separators deliver exceptional iron removal with zero energy consumption. The innovative pneumatic cylinder drive systems and multi-layer configurations ensure thorough contamination removal while maintaining complete automation. These advanced drawer magnets enable continuous operation with minimal intervention, making the CQZ series ideal for modern production lines requiring consistent purity. The robust construction of these magnetic grate separators guarantees long-term reliability with minimal maintenance requirements.

CQZ Drawer Magnets & Magnetic Grate Separator Key Features

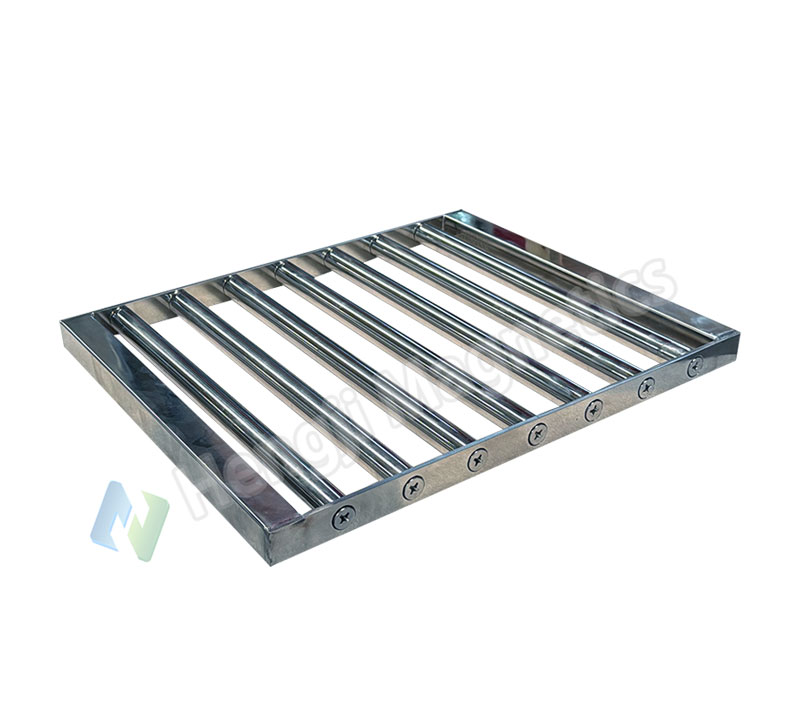

Advanced Magnetic System

Utilizing high-performance NdFeB rare-earth magnets, these drawer magnets deliver powerful magnetic force exceeding 12,000 Gauss. The comprehensive grid-style array and multi-layer rod design of these magnetic grate separators ensure progressive filtration for complete iron removal, maximizing effective working area while maintaining stable performance.

Intelligent Pneumatic Control

Featuring automated cylinder mechanisms that sequentially retract magnetic rods, these drawer magnets enable efficient self-cleaning. The programmable relay system allows flexible interval adjustments, while pressure monitoring ensures reliable operation above 0.3MPa, making these magnetic grate separators ideal for continuous unmanned production.

Premium Materials & Construction

Constructed with SUS304 stainless steel contact parts, these drawer magnets offer excellent corrosion resistance and contamination prevention. The compact structure of these magnetic grate separators facilitates easy installation and maintenance, while superior sealing performance ensures quiet operation and extended service life.

Safety & Environmental Protection

Operating without external power, these drawer magnets provide energy-efficient separation. The fully enclosed magnetic grate separators eliminate dust pollution while multiple safety devices ensure reliable, environmentally compliant operation certified under ISO9001 quality standards.

CQZ Drawer Magnets & Magnetic Grate Separator Working Principle

The CQZ automatic pneumatic separator operates through an integrated system of permanent magnetic separation and intelligent pneumatic control, providing efficient ferrous contamination removal in powder processing applications.

Feeding & Separation Process

As powdered materials enter through the inlet, they pass through the grid of powerful drawer magnets. Ferrous contaminants are immediately extracted and securely held on the magnetic rod surfaces of these advanced magnetic grate separators. The purified materials continue uninterrupted through the system, discharging from the outlet while maintaining product purity and processing efficiency.

Automatic Cleaning Operation

The pneumatic control system sequentially retracts magnetic rods within the drawer magnets, releasing captured metals through dedicated discharge outlets. The cleaning frequency and duration of these magnetic grate separators are fully adjustable based on material contamination levels, ensuring optimal performance while minimizing production interruptions.

Continuous Operation Cycle

Intelligent program control alternates seamlessly between processing and cleaning phases in the drawer magnets. This automated sequencing in the magnetic grate separators ensures uninterrupted production flow while maintaining consistent separation efficiency, maximizing both equipment utilization and overall productivity in continuous manufacturing environments.

CQZ Drawer Magnets & Magnetic Grate Separator Applications

Primary Industries

These advanced drawer magnets provide essential iron removal in food processing for flour, starch, and seasonings. The efficient magnetic grate separators serve plastics manufacturing by controlling metal contamination in pellets, while chemical and pharmaceutical industries utilize this technology for raw material purification. The equipment also processes ceramic powders and wood materials, demonstrating exceptional versatility across multiple sectors requiring precise ferrous separation.

Operating Conditions

The drawer magnets operate effectively at altitudes up to 3000 meters within -20℃ to +40℃ temperature ranges. These reliable magnetic grate separators handle up to 90% relative humidity at 25℃, functioning in both indoor and outdoor installations with a compressed air source ≥0.3MPa, ensuring consistent performance across diverse environmental conditions.

Special Applications

The technology serves precision manufacturing with high purity requirements and continuous automated production lines. The drawer magnets meet strict cleanliness standards while the magnetic grate separators offer explosion-proof capabilities for hazardous environments, providing comprehensive solutions for specialized industrial applications where reliability and safety are paramount.

CQZ Drawer Magnets & Magnetic Grate Separator Services

Professional Technical Support

We provide customized separation solutions and equipment selection guidance for drawer magnets. Our experts offer installation optimization and specialized solutions for unique operating conditions, ensuring your magnetic grate separators deliver optimal performance in specific applications.

Installation & Commissioning

Detailed foundation drawings and installation requirements are provided for drawer magnets. We deliver on-site installation guidance with technical coordination, plus complete commissioning support and trial operation assistance for your magnetic grate separators systems.

Operation Training

Comprehensive training covers equipment principles and operational procedures for both drawer magnets and magnetic grate separators. We provide essential maintenance knowledge and troubleshooting methodologies to ensure your team can effectively operate and maintain the equipment.

After-Sales Support System

Our complete quality assurance includes performance commitments for all drawer magnets. We conduct regular equipment evaluations and maintenance follow-ups for your magnetic grate separators, supported by genuine spare parts supply and rapid technical response to ensure continuous operational efficiency.

Categories

Categories