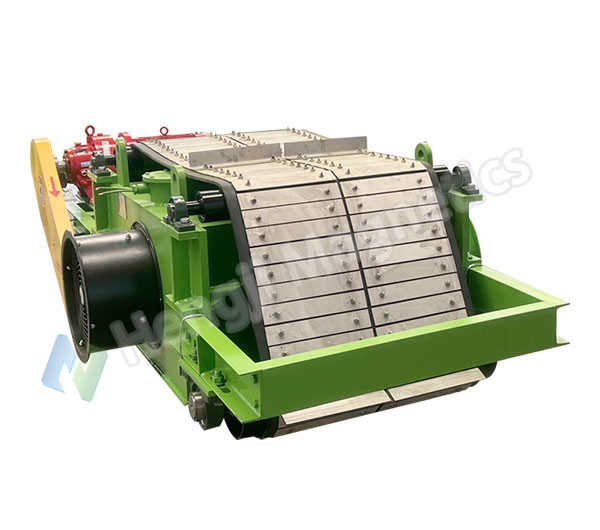

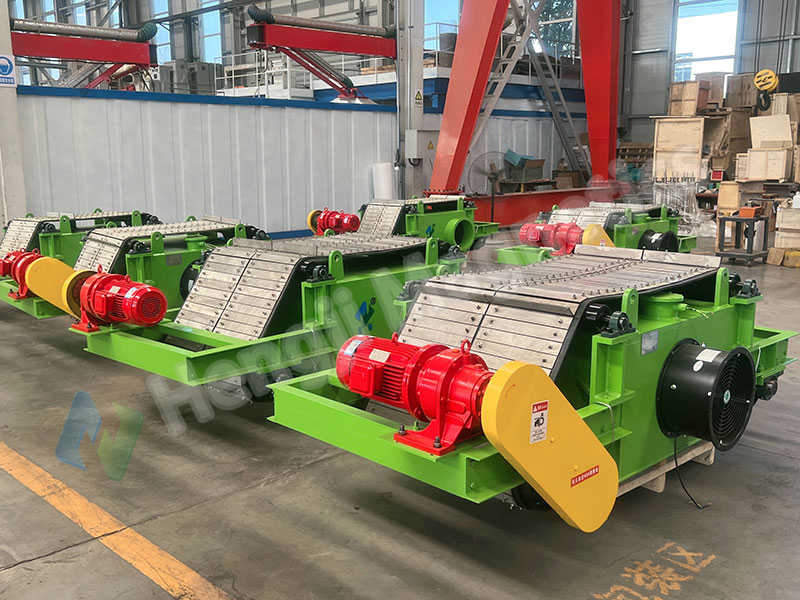

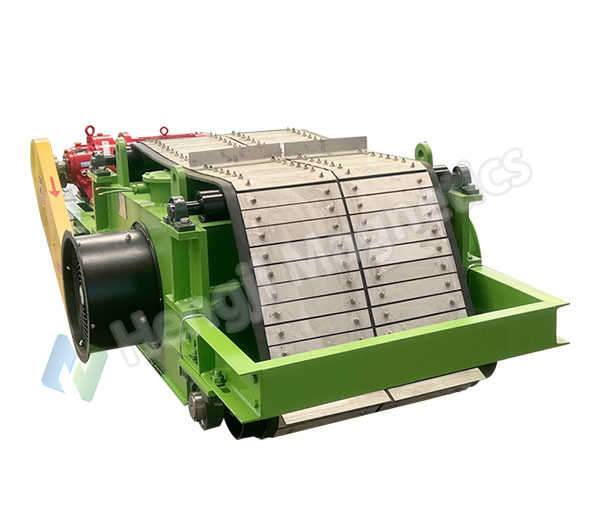

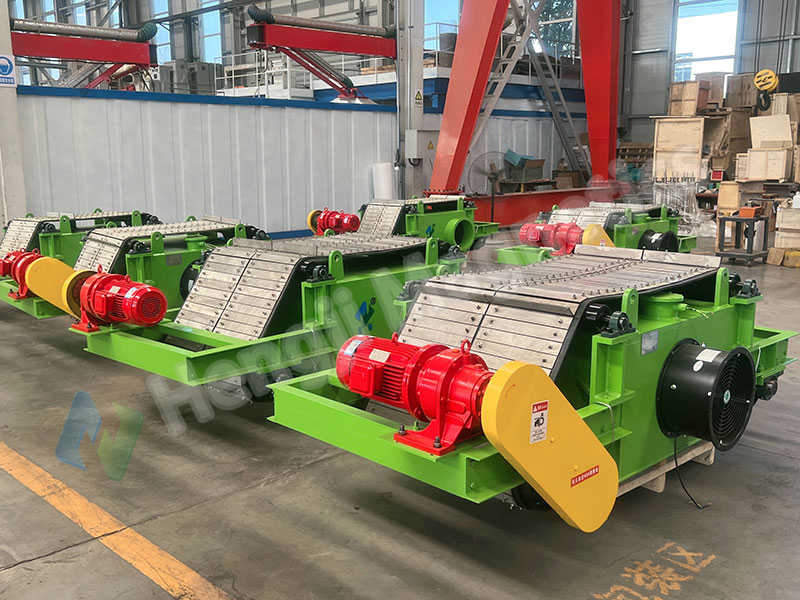

RCDC Air-cooled Cross Belt Electric Magnetic Separator Product Overview

The RCDC series is an air-cooled electromagnetic separator. This advanced cross belt magnetic separator integrates fan cooling and automated systems.

It features a computer-optimized magnetic circuit and is ISO9001 certified. This electric separator effectively removes ferrous contaminants from 0.1-35kg.

Its forced air cooling ensures reliable performance. This robust cross belt magnetic separator is designed for demanding industrial environments.

It is ideal for continuous operation under high temperatures and dust. This electric separator delivers consistent performance in mining, construction, and power generation.

RCDC Air-cooled Cross Belt Electric Magnetic Separator Key Features

Advanced Magnetic Circuit

-

Utilizes a DT4 electrical pure iron core with an optimized magnetic structure.

-

This cross belt magnetic separator delivers ≥70mT magnetic strength at rated height.

-

It provides a 200mm penetration depth for deep material cleaning.

-

It maintains maximum attraction force throughout its defined working distance.

Enhanced Cooling Technology

-

Features an integrated forced air cooling system.

-

This reduces temperature rise by 30% compared to natural cooling methods.

-

It enables reliable 24-hour continuous operation.

-

This is a key advantage for the electric separator in demanding industrial conditions.

Fully Automatic Cleaning

-

A cycloidal reducer drives the cleaning belt at 0.15-0.25m/s.

-

A crowned drum design is incorporated for better belt tracking.

-

The system achieves >98% cleaning efficiency.

-

This high efficiency is a standard feature of the cross belt magnetic separator.

Energy Efficient Design

Reducing power consumption by 30% with noise below 79dB, this cross belt magnetic separator complies with JB/T7689-2004 standards.

Superior Protection

Class F insulated vacuum-encapsulated coils provide IP65 rating, allowing this electric separator to operate in -20℃ to +40℃ environments.

Safety Enhancement

Integrated rubber scraper eliminates belt damage risks, ensuring safe operation of the cross belt magnetic separator.

RCDC Air-cooled Cross Belt Electric Magnetic Separator Working Principle

Working Principle Overview

-

During operation, the rectification control system supplies DC power to the excitation coils.

-

This generates a high-intensity magnetic field at the pole surface.

-

When conveyed materials pass beneath the separator, ferrous contaminants are extracted.

-

They are held firmly against the cleaning belt surface.

-

This is the core action of the advanced cross belt magnetic separator.

Magnetic Extraction & Transport

-

The reduction motor drives the belt system continuously.

-

This transports the captured tramp iron to a designated non-magnetic zone.

-

An automatic scraping mechanism then discharges the material into collection containers.

-

This integrated cleaning cycle is key to the operation of the electric separator.

Cooling & Intelligent Control

-

A forced air cooling system provides continuous heat dissipation.

-

This is achieved through specially designed air ducts.

-

The system maintains stable operating temperatures for reliability.

-

When connected with a metal detector, the cross belt magnetic separator can operate in an energy-saving mode.

-

In this mode, the electric separator applies power only when ferrous contamination is detected.

Operational Efficiency

-

This intelligent operation mode enables significant energy savings.

-

The electric separator can achieve average energy savings of up to 40%.

-

This is achieved while maintaining highly effective ferrous material removal.

-

The system is designed for reliability across various demanding industrial applications.

RCDC Air-cooled Cross Belt Electric Magnetic Separator Product Parameters

RCDC Air-cooled Cross Belt Electric Magnetic Separator Applications

Mining Operations Applications

-

The cross belt magnetic separator performs pre-concentration and tramp iron removal.

-

It is used in iron ore and copper ore processing lines.

-

It effectively protects expensive crushers and grinding equipment from damage.

-

The electric separator ensures operational safety and reliability in these critical mineral processing applications.

Cement Industry Applications

-

It processes raw materials like limestone and sandstone.

-

The cross belt magnetic separator prevents metal damage to key equipment.

-

This includes protection for raw mills and roller presses.

-

This electric separator helps maintain high production efficiency and equipment longevity in cement manufacturing.

Thermal Power Generation Applications

-

It is installed in coal handling systems at power plants.

-

The cross belt magnetic separator protects critical components like coal pulverizers and boiler systems.

-

The electric separator ensures continuous, reliable power generation.

-

It achieves this by systematically removing ferrous contaminants from the coal stream.

Steel Metallurgy Applications

-

It removes tramp iron from sinter and pellet production lines.

-

This cross belt magnetic separator improves the quality of the feed for smelting.

-

The electric separator enhances overall metallurgical process efficiency and product purity.

Port Facilities & Chemical Processing Applications

-

In ports, the cross belt magnetic separator performs metal separation during bulk material handling.

-

In chemical plants, the electric separator prevents costly catalyst contamination.

-

It achieves this by purifying raw materials before processing.

Resource Recycling Applications

-

This cross belt magnetic separator recovers valuable ferrous metals from various scrap materials.

-

The electric separator enhances resource utilization efficiency.

-

This is critical across a wide range of modern recycling applications.

RCDC Air-cooled Cross Belt Electric Magnetic Separator Services

Custom Engineering

-

We provide personalized engineering solutions.

-

These are based on your specific conveyor parameters for the cross belt magnetic separator.

-

Key parameters include belt width (650-2000mm), belt speed (≤4.5m/s), and material thickness.

-

Our custom configurations ensure the optimal performance of every electric separator unit.

Installation Guidance

-

We offer comprehensive technical support for various installation methods.

-

This includes guidance for both QX (inclined) and SP (horizontal) installations of the cross belt magnetic separator.

-

Support covers critical steps like suspension height calculations.

-

It also includes advice on non-magnetic roller configuration for the best results.

Commissioning Services

-

Our engineers provide on-site professional adjustment of the cleaning belt tracking.

-

We conduct thorough magnetic field strength testing.

-

We optimize all critical electrical parameters for your electric separator.

-

This ensures peak performance from the first day of operation.

Maintenance Training

-

We deliver comprehensive training for your maintenance team.

-

Training covers all daily inspection procedures.

-

It includes practical guidance on bearing lubrication.

-

It teaches proper belt tension checking and insulation testing.

-

This training is specific to the cross belt magnetic separator.

Spare Parts Supply

-

We guarantee the supply of 100% genuine components.

-

This includes critical parts like excitation coils, reduction motors, and bearings.

-

All parts for the electric separator come with a 2-year factory warranty.

Technical Upgrades & Monitoring

-

We offer retrofit services for performance improvements.

-

Services include magnetic system upgrades and control system modernization.

-

Optional IoT modules are available.

-

These modules enable remote, real-time monitoring of the cross belt magnetic separator.

System Performance Summary

-

This advanced electric separator system demonstrates exceptional performance stability.

-

It utilizes innovative air cooling technology.

-

It features a highly reliable automatic cleaning system.

-

The system significantly reduces long-term operational costs.

-

It maintains highly efficient tramp iron removal throughout its service life.

Categories

Categories