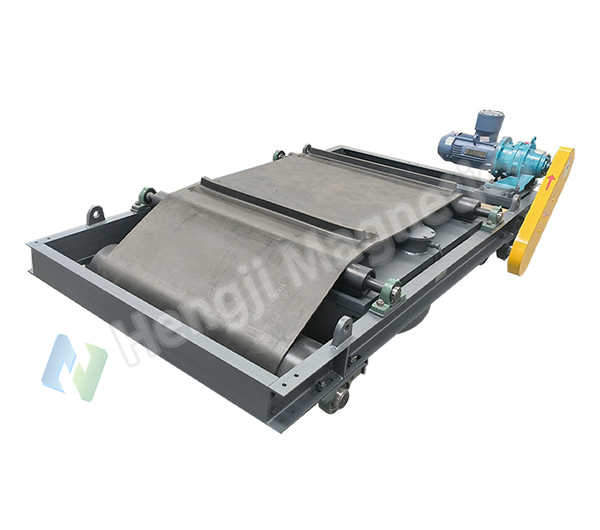

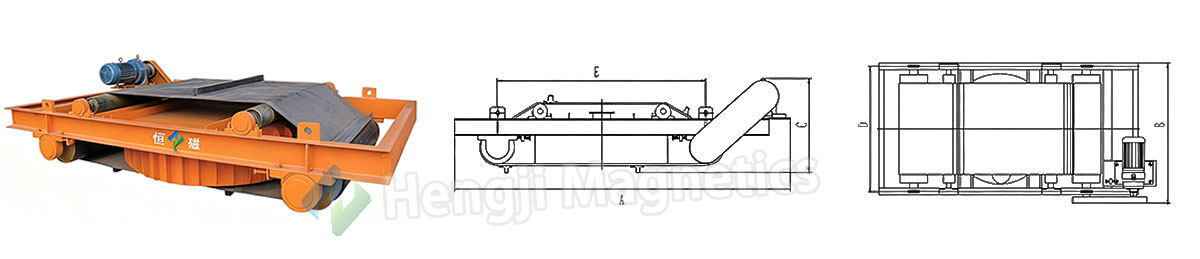

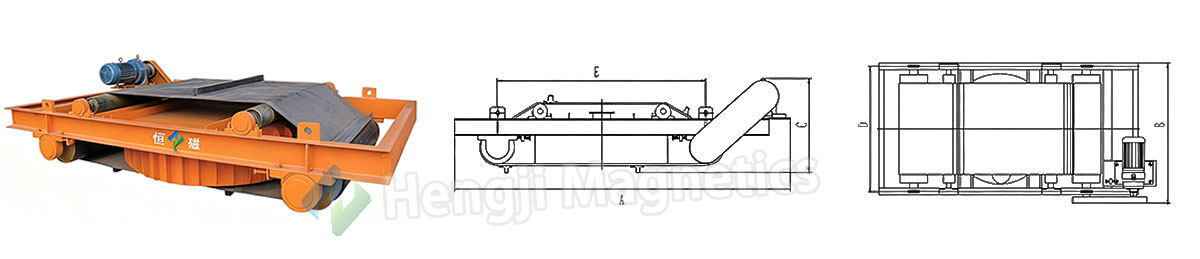

RCDD Electro Overband magnets & Belt Magnetic Separator Product Overview

The RCDD series is a self-cleaning electromagnetic separator. These highly efficient electro overband magnets use advanced electromagnetic technology.

They feature a fully sealed construction with vacuum-potted coils. This over belt magnetic separator has self-cooling capability for reliable operation.

It incorporates an automatic cleaning mechanism with drive motors. This electro overband magnets system removes impurities without interrupting production.

Installed above conveyor sections, these robust over belt magnetic separator units are ideal for mining and metallurgical applications.

They maintain reliable performance in demanding environments. These electro overband magnets require minimal maintenance for continuous operation.

RCDD Electro Overband magnets & Belt Magnetic Separator Key Features

Powerful Magnetic Performance

-

A computer-optimized magnetic circuit delivers deep penetration.

-

This enables electro overband magnets to remove ferrous contaminants weighing 0.1-50kg.

-

The over belt magnetic separator ensures thorough iron extraction.

-

It works effectively with various bulk materials.

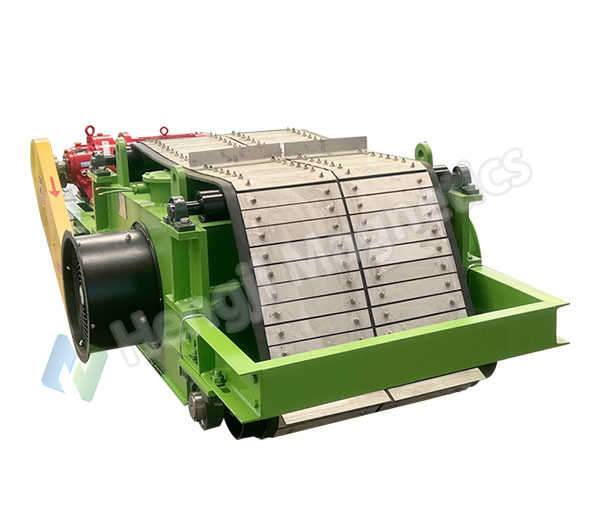

Robust Construction & Automation

-

A fully sealed design with IP65 protection is standard.

-

This ensures reliable operation of electro overband magnets in harsh, dusty, or wet environments.

-

An automatic self-cleaning system with a cycloidal reducer motor is featured.

-

This allows the over belt magnetic separator to operate continuously without manual intervention.

Energy Efficiency & Control

-

The system features an optimized design that reduces power consumption by over 30%.

-

Operational noise is kept below 65dB.

-

An intelligent control system is integrated into the over belt magnetic separator.

-

It provides precise magnetic adjustment and comprehensive overload protection.

Durability & Safety

-

A crowned drive pulley ensures automatic belt tracking for stable operation.

-

Sealed bearing housings extend the service life of electro overband magnets.

-

An integrated rubber scraper is included in the design.

-

This eliminates the risk of belt damage in the over belt magnetic separator.

Maintenance Advantages

-

The system employs a modular design.

-

This facilitates quick component replacement in the over belt magnetic separator.

-

Modularity minimizes operational downtime during maintenance.

-

It ensures high overall operational efficiency for electro overband magnets.

RCDD Electro Overband magnets & Belt Magnetic Separator Working Principle

Working Principle Overview

-

The RCDD electro overband magnets operate on electromagnetic induction principles.

-

When energized, the excitation coil generates a powerful DC magnetic field.

-

This field is concentrated through a high-purity iron core assembly.

-

This process creates a strong magnetic zone beneath the equipment.

Magnetic Extraction Process

-

As conveyed bulk materials pass through this magnetic zone, ferrous contaminants are extracted.

-

They are held firmly against the surface of the separator.

-

This extraction is a core function of the over belt magnetic separator.

Integrated Cleaning System

-

The separator features an integrated, automated cleaning system.

-

This system includes a continuously moving belt driven by a reduction motor.

-

The design is integral to the operation of electro overband magnets.

Automated Discharge

-

The moving belt automatically transports captured tramp iron.

-

It moves the iron away from the active magnetic field to a designated discharge point.

-

This feature ensures the continuous operation of the over belt magnetic separator.

Operational Benefits

-

The electro overband magnets maintain consistent iron removal efficiency.

-

This process does not interrupt the main material flow on the conveyor.

-

These characteristics make the over belt magnetic separator ideal for continuous processing.

-

It is suitable for a wide range of industrial applications.

RCDD Electro Overband magnets & Belt Magnetic Separator Product Parameters

RCDD Electro Overband magnets & Belt Magnetic Separator Applications

Power Generation Applications

-

Electro overband magnets are essential in coal handling systems at thermal power plants.

-

They protect critical equipment like pulverizers and boilers from tramp iron damage.

-

The over belt magnetic separator ensures reliable, continuous operation.

-

This is vital for the efficiency of power generation facilities.

Mining & Metallurgical Operations

-

In mining, electro overband magnets remove tramp iron before crushing stages.

-

This significantly extends the service life of expensive crushers.

-

For metallurgical processing, the over belt magnetic separator purifies raw materials.

-

This purification improves the quality of the final product in smelting operations.

Cement & Coal Industries

-

In cement production, electro overband magnets remove iron contamination.

-

They protect equipment on raw meal and clinker conveying lines.

-

In coal preparation plants, the over belt magnetic separator extracts ferrous materials.

-

This occurs during critical coal washing and processing operations.

Chemical & Port Facilities

-

Chemical plants utilize electro overband magnets for equipment protection.

-

They are installed in raw material handling systems to prevent damage.

-

Port facilities employ the over belt magnetic separator for metal separation.

-

This is crucial during bulk material loading and unloading operations.

Waste Recycling

-

In recycling applications, electro overband magnets enable efficient metal recovery.

-

They are deployed in municipal solid waste (MSW) processing lines.

-

The over belt magnetic separator supports resource conservation efforts.

-

This contributes directly to environmental sustainability initiatives.

RCDD Electro Overband magnets & Belt Magnetic Separator Services

Technical Consultation

-

We provide professional selection and configuration guidance.

-

Our recommendations are based on your specific material characteristics and conveyor parameters.

-

This ensures the optimal setup for your electro overband magnets.

-

It also guarantees an efficient over belt magnetic separator system.

Installation & Commissioning

-

We offer on-site installation supervision by our engineers.

-

This guarantees proper positioning and alignment of electro overband magnets.

-

Correct installation is key to achieving maximum iron removal efficiency.

-

Our commissioning services then optimize the performance of your over belt magnetic separator.

Operator Training

-

We deliver comprehensive, hands-on training programs.

-

Training covers all routine operation procedures.

-

It includes detailed maintenance procedures and schedules.

-

We teach effective troubleshooting techniques.

-

This training applies to both your electro overband magnets and over belt magnetic separator equipment.

After-Sales Support

-

We provide 24/7 technical assistance for any operational issues.

-

This prompt support specifically addresses problems with electro overband magnets.

-

The goal is to minimize production interruptions and downtime.

-

This ensures the continuous, reliable operation of your over belt magnetic separator systems.

Spare Parts & Upgrades

-

We supply 100% genuine replacement components.

-

This maintains the original performance standards of your equipment.

-

Our enhancement solutions include control system modernization.

-

These upgrades are available for your electro overband magnets.

-

We also offer magnetic circuit improvements for your over belt magnetic separator units.

Maintenance & Engineering

-

Our scheduled inspection services include professional magnetic field testing.

-

We conduct thorough mechanical evaluations during maintenance visits.

-

We offer custom engineering services for specialized applications.

-

This can provide unique designs for electro overband magnets.

-

It also creates tailored solutions for over belt magnetic separator installations in unique scenarios.

Categories

Categories