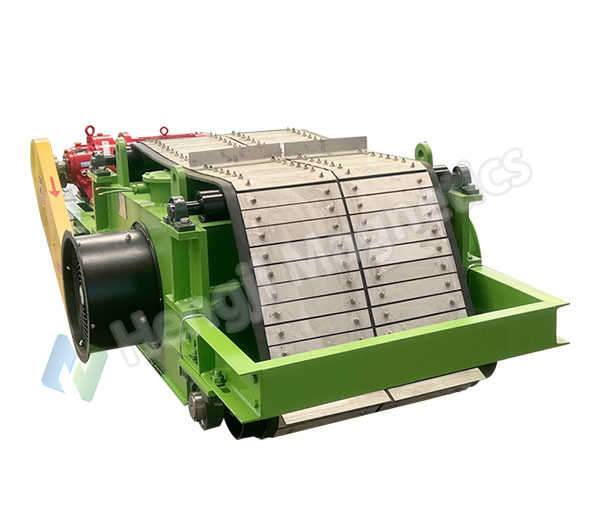

RCDE Oil-cooled Electric Magnets & Conveyor Magnetic Separator Product Overview

The RCDE series is an oil-cooled electromagnetic separator. It represents a substantial upgrade, delivering enhanced performance.

These sophisticated electric magnets incorporate unique oil-cooling technology. Their fully sealed structure resolves the challenge of excessive coil temperature.

Engineered for continuous industrial applications, this high-performance conveyor magnetic separator ensures stable magnetic output. It provides exceptional heat dissipation and reduced maintenance.

The integrated oil circulation system maintains consistent performance. These reliable electric magnets are optimal for non-stop operations.

This conveyor magnetic separator offers maximum reliability across various material handling environments.

RCDE Oil-cooled Electric Magnets & Conveyor Magnetic Separator Key Features

Exceptional Thermal Management

-

The system features an integrated dual-circuit oil cooling system.

-

It provides 3-4 times more heat dissipation area than conventional models.

-

These advanced electric magnets feature Class F insulation (withstanding 155°C).

-

They maintain a ≤80K temperature rise during operation.

-

Innovative wave-shaped cooling fins reduce core temperatures by 15-20°C.

-

This engineering ensures reliable performance in the heavy-duty conveyor magnetic separator.

Powerful Magnetic System

-

A computer-optimized magnetic circuit is used.

-

It delivers a 400-600mm penetration depth for deep cleaning.

-

DT4 electrical pure iron maintains a stable magnetic flux of 120-150mT.

-

These robust electric magnets can extract ferrous objects weighing 0.1 to 50kg.

-

This makes the conveyor magnetic separator highly effective across various industrial applications.

Robust Structural Design

-

The equipment features a fully sealed IP65 construction.

-

This provides protection against dust, water, and other environmental hazards.

-

Vacuum potting technology is used to completely isolate the coils.

-

Critical structural components are made from stainless steel.

-

This offers 50% better corrosion resistance.

-

These features enhance the durability of both the electric magnets and the complete conveyor magnetic separator system.

Intelligent Control System

-

A silicon-controlled rectifier (SCR) enables DC voltage adjustment (0-220V).

-

The system includes integrated electrical protection circuits.

-

Optional interconnection with metal detectors is available.

-

This allows for energy-saving operation.

-

These intelligent controls optimize the performance of the electric magnets and the overall conveyor magnetic separator.

RCDE Oil-cooled Electric Magnets & Conveyor Magnetic Separator Working Principle

Working Principle Overview

-

The RCDE separator operates on an integrated system.

-

It combines electromagnetic induction with advanced forced oil cooling technology.

-

This combination delivers highly reliable separation performance.

Electromagnetic Generation System

-

A rectifier cabinet converts AC power to regulated DC current.

-

This current energizes the powerful excitation coils.

-

The coils within these electric magnets generate intensive magnetic fields.

-

The fields are precisely directed through specially designed magnetic poles.

-

This creates the foundation for exceptional ferrous capture capability.

-

This capability is central to the conveyor magnetic separator.

Oil Cooling Circulation System

-

Transformer oil circulates forcibly through an extensive cooling pipe network.

-

This effectively dissipates heat generated during continuous operation.

-

This sophisticated thermal management system is critical.

-

It ensures the electric magnets maintain optimal operating temperatures.

-

Heated oil passes through external condensers for cooling.

-

The oil then returns in a sealed, closed-loop cycle.

-

This cycle guarantees consistent, long-term performance of the system.

Separation Process

-

As materials transport along the conveyor line, ferrous contaminants are extracted.

-

They are powerfully drawn through magnetic attraction.

-

The contaminants adhere to the surface of the conveyor magnetic separator.

-

Non-magnetic materials continue their trajectory completely unaffected.

-

This enables the advanced system to provide continuous protection.

-

It safeguards downstream processing equipment from metal damage.

-

The process maintains uninterrupted material flow for maximum productivity.

RCDE Oil-cooled Electric Magnets & Conveyor Magnetic Separator Product Parameters

RCDE Oil-cooled Electric Magnets & Conveyor Magnetic Separator Application

Power Generation Industry

-

The conveyor magnetic separator efficiently processes coal in thermal power plants.

-

It handles high capacities, ranging from 1000 to 3000 tons per hour.

-

These reliable electric magnets also serve biomass power facilities.

-

They are used for critical fuel pre-treatment.

-

Their role is to protect downstream equipment from damaging ferrous contamination.

Mining and Metallurgy

-

In iron ore processing plants, the conveyor magnetic separator purifies raw materials.

-

This purification occurs before the crushing and grinding stages.

-

These powerful electric magnets are equally effective in other systems.

-

They are used in non-ferrous metal ore pre-treatment.

-

They ensure material purity and provide essential equipment protection.

Building Materials and Chemicals

-

The conveyor magnetic separator performs essential iron removal.

-

This is critical in cement plants prior to raw material grinding.

-

For glass manufacturing, these advanced electric magnets purify quartz sand.

-

This process maintains high product quality.

-

The equipment serves both the building material and chemical processing industries.

Special Applications

-

At port terminals, the conveyor magnetic separator integrates into bulk handling systems.

-

It performs metal separation during loading/unloading operations.

-

In waste-to-energy plants, these versatile electric magnets process RDF fuel streams.

-

They remove metals to protect combustion systems.

-

This demonstrates the system’s adaptability.

-

It meets the needs of various industrial sectors requiring robust ferrous separation solutions.

RCDE Oil-cooled Electric Magnets & Conveyor Magnetic Separator Services

Categories

Categories