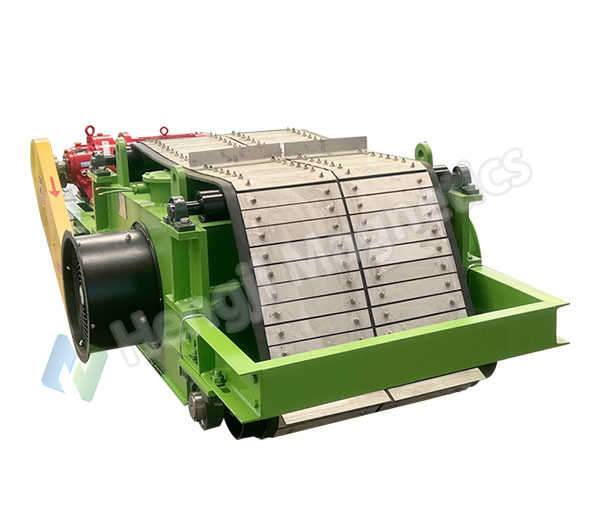

RCDF Oil-Cooled Self-Cleaning Electro Magnetic Separation Cross Belt Magnets Product Overview

The RCDF series is an oil-cooled self-cleaning electromagnetic separator. It represents a significant evolution in electro magnetic separation technology.

This advanced system integrates oil circulation cooling with automated cleaning. It delivers exceptional performance in demanding industrial applications.

Engineered for continuous operation, these robust cross belt magnets remove ferrous contaminants from material streams. They provide reliable protection for downstream equipment.

Their completely sealed construction ensures powerful magnetic force and rapid heat dissipation. The RCDF series demonstrates particular strength in high-capacity applications.

These sophisticated cross belt magnets are designed for uninterrupted performance. They meet critical requirements for minimal maintenance in automated environments.

RCDF Oil-Cooled Self-Cleaning Electro Magnetic Separation Cross Belt Magnets Key Features

Exceptional Magnetic Performance

-

Features a computer-optimized magnetic circuit.

-

This advanced electro magnetic separation system achieves a 400-600mm penetration depth.

-

It maintains a magnetic field strength of 120-150mT.

-

These powerful cross belt magnets extract ferrous materials weighing 0.1-35kg.

-

The system maintains ≥85% magnetic pole surface uniformity.

-

This ensures consistent, high separation efficiency.

Advanced Cooling System

-

Utilizes a unique dual-circuit oil cooling system.

-

This design improves heat dissipation efficiency by 40%.

-

It uses #25 transformer oil (insulation strength ≥35kV/2.5mm).

-

The system maintains coil temperature rise within 65K.

-

This ensures reliable continuous operation.

-

It is critical for these cross belt magnets in demanding electro magnetic separation applications.

RCDF Oil-Cooled Self-Cleaning Electro Magnetic Separation Cross Belt Magnets Working Principle

Exceptional Magnetic Performance

-

Features a computer-optimized magnetic circuit.

-

This advanced electro magnetic separation system achieves a 400-600mm penetration depth.

-

It maintains a magnetic field strength of 120-150mT.

-

These powerful cross belt magnets extract ferrous materials weighing 0.1-35kg.

-

The system maintains ≥85% magnetic pole surface uniformity.

-

This ensures consistent, high separation efficiency.

Advanced Cooling System

-

Utilizes a unique dual-circuit oil cooling system.

-

This design improves heat dissipation efficiency by 40%.

-

It uses #25 transformer oil (insulation strength ≥35kV/2.5mm).

-

The system maintains coil temperature rise within 65K.

-

This ensures reliable continuous operation.

-

It is critical for these cross belt magnets in demanding electro magnetic separation applications.

Reliable Automatic Cleaning

-

Equipped with IP55-rated cycloidal reducer motors.

-

Features crowned drive drums with automatic tracking.

-

These cross belt magnets have adjustable cleaning belt speeds of 0.2m/s.

-

This allows for optimized discharge efficiency.

-

The cleaning system is integral to automated electro magnetic separation processes.

Superior Environmental Adaptation

-

The system has a fully sealed IP65 construction.

-

It uses vacuum potting technology for complete component protection.

-

Critical components are made from stainless steel.

-

This extends service life by 50%.

-

It enhances the overall durability of these industrial cross belt magnets.

Intelligent Control System

-

A silicon-controlled rectifier (SCR) enables DC voltage adjustment (0-220V).

-

The system includes comprehensive electrical protection.

-

Optional PLC control is available.

-

This facilitates fully automated, programmable operation.

-

The control system is designed for this advanced electro magnetic separation equipment.

RCDF Oil-Cooled Self-Cleaning Electro Magnetic Separation Cross Belt Magnets Product Parameters

RCDF Oil-Cooled Self-Cleaning Electro Magnetic Separation Cross Belt Magnets Applications

RCDF Oil-Cooled Self-Cleaning Electro Magnetic Separation Cross Belt Magnets Services

Categories

Categories