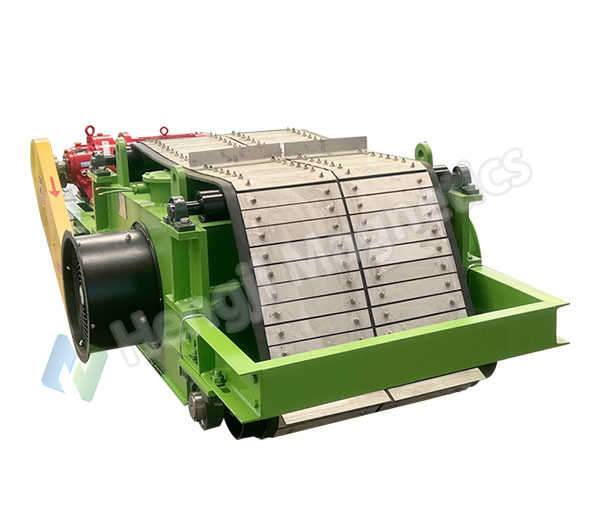

RCDFJ Oil Forced Circulation Electricity Magnets Overbelt Magnetic Separator Product Overview

The RCDFJ series sets a new standard for demanding applications. This advanced overbelt magnetic separator features a patented forced oil cooling system.

It enables continuous high-capacity operation beyond conventional limits. These robust electricity magnets integrate oil-cooling with automated cleaning.

They deliver unparalleled performance in high-volume, high-dust environments. The RCDFJ series excels in large-scale thermal power plants and coal facilities.

This premium overbelt magnetic separator also serves major metallurgical processing systems. It maintains consistent performance under extreme conditions.

These reliable electricity magnets ensure continuous protection for downstream machinery. They provide maximum reliability for non-stop operations.

RCDFJ Oil Forced Circulation Electricity Magnets Overbelt Magnetic Separator Key Features

Exceptional Magnetic Performance

-

Utilizes a DT4 electrical pure iron core and multi-layer oxidized copper wire coils.

-

This overbelt magnetic separator achieves a powerful 150mT magnetic field.

-

It provides 40% higher attraction force than standard models.

-

A unique dual cooling pipe system is incorporated.

-

This maintains coil temperatures below 65°C during operation.

-

This ensures consistent, high-level performance from these powerful electricity magnets.

Intelligent Cooling System

-

The system features a dedicated oil circulation pump (≥25L/min flow rate).

-

It integrates an axial fan array with continuous temperature monitoring.

-

Automatic alarm protection is standard for safety.

-

This system safeguards the overbelt magnetic separator units.

-

It enables reliable 24/7 continuous operation.

Fully Automated Cleaning

-

Equipped with a crowned drive drum for better belt tracking.

-

Powered by a cycloidal reducer motor (IP55 rated).

-

This overbelt magnetic separator offers adjustable belt speeds (0.15-0.25m/s).

-

An integrated rubber scraper ensures efficient material discharge.

-

This is a key feature of these advanced electricity magnets.

Military-Grade Reliability

-

Features fully sealed cast steel bearing seats with IP6X protection.

-

Uses vacuum-encapsulated Class F insulation coils, rated to 155°C.

-

These construction elements are key to the durability of these electricity magnets.

-

A bellows-type oil conservator provides automatic volume compensation.

-

This ensures long-term operational reliability of the overbelt magnetic separator.

RCDFJ Oil Forced Circulation Electricity Magnets Overbelt Magnetic Separator Working Principle

Working Principle Overview

Electromagnetic Separation System

-

A rectifier cabinet converts 380V AC to DC220V power.

-

This power energizes the excitation coils.

-

The coils generate powerful, directional magnetic fields.

-

These sophisticated electricity magnets utilize DT4 magnetic poles.

-

The poles form highly efficient closed magnetic circuits.

-

This maximizes separation efficiency for the overbelt magnetic separator.

-

Ferrous materials are effectively extracted from conveyed bulk loads.

Oil Circulation Cooling

-

Heated oil is pressurized through a dedicated circulation system.

-

It flows into tubular condensers for cooling.

-

Axial fans provide forced air cooling (air volume ≥3000m³/h).

-

This advanced thermal management is critical.

-

It maintains optimal operating temperatures for the overbelt magnetic separator.

-

Oil temperature differentials are controlled within 8°C.

-

This ensures consistent, reliable performance.

Automated Cleaning Process

-

Captured ferrous materials are continuously transported.

-

This is done via the cleaning belt to designated collection points.

-

A PLC system automatically initiates cleaning cycles.

-

Cleaning intervals are adjustable (15-60 minutes).

-

This automation ensures uninterrupted operation.

-

It is essential for these high-capacity electricity magnets.

-

The system performs reliably in demanding industrial environments.

RCDFJ Oil Forced Circulation Electricity Magnets Overbelt Magnetic Separator Product Parameters

RCDFJ Oil Forced Circulation Electricity Magnets Overbelt Magnetic Separator Industrial Applications

Energy Sector Applications

-

In coal-fired power plants, the overbelt magnetic separator processes high volumes.

-

It handles up to 3000 tons per hour in coal handling systems.

-

It effectively removes damaging metal contaminants from coal.

-

These powerful electricity magnets also serve coal preparation plants.

-

They are used for dense medium (magnetite/ferrosilicon) recovery.

-

This process ensures operational efficiency and equipment protection.

Metallurgical Industry Applications

-

The system handles sintered ore conveyor separation.

-

High-temperature versions are available, rated for environments up to 80°C.

-

This heavy-duty overbelt magnetic separator integrates into critical systems.

-

It is used in blast furnace raw material pretreatment.

-

In these applications, these advanced electricity magnets perform a vital role.

-

They safeguard critical downstream equipment from ferrous contamination and damage.

Special Applications

-

At bulk port terminals, the overbelt magnetic separator coordinates operations.

-

It works seamlessly with large equipment like bucket wheel reclaimers.

-

This ensures continuous metal extraction during unloading.

-

In waste-to-energy plants, these reliable electricity magnets purify RDF (Refuse Derived Fuel) streams.

-

They protect sensitive processing machinery from metal damage.

-

The system maintains consistent throughput.

-

It performs reliably in these challenging material handling applications.

RCDFJ Oil Forced Circulation Electricity Magnets Overbelt Magnetic Separator Services

Categories

Categories