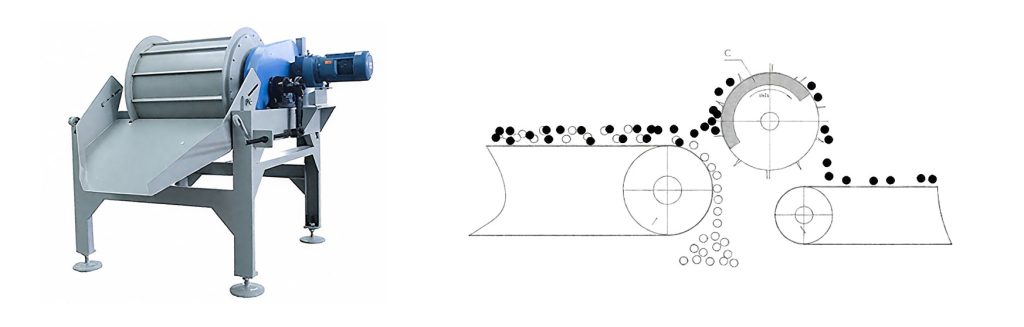

CTZS Upward Suction Permanent Drum Type Magnetic Separator Product Overview

The CTZS Series is an advanced over-belt drum type magnetic separator. It is designed for scrap metal processing, slag treatment, and waste sorting.

Utilizing high-performance NdFeB magnets, this robust permanent magnetic drum separator delivers exceptional magnetic strength. It performs reliably in challenging environments.

This specialized drum type magnetic separator effectively protects belts during high-volume processing. It maintains consistent performance while addressing key industry challenges.

Its sophisticated magnetic circuit ensures deep penetration through material layers. This permanent magnetic drum separator efficiently extracts both large and weakly magnetic contaminants.

This reliable drum type magnetic separator provides long-term performance with minimal maintenance. It is suitable for various demanding industrial applications.

CTZS Upward Suction Permanent Drum Type Magnetic Separator Key Features

Exceptional Magnetic Performance

-

This advanced drum type magnetic separator utilizes high-grade NdFeB magnets.

-

It features computer-optimized magnetic circuits for precision.

-

The system delivers strong magnetic intensity and deep penetration.

-

This permanent magnetic drum separator maintains exceptionally stable performance.

-

It exhibits less than 5% magnetic decay over an eight-year period.

-

This ensures consistent, high separation efficiency throughout its long operational lifespan.

Robust Structural Design

-

The equipment features an integrated, sturdy construction.

-

It uses a durable stainless steel drum shell with optional surface treatments.

-

This design allows the drum type magnetic separator to withstand harsh operating conditions.

-

All components of this permanent magnetic drum separator are built for durability.

-

They provide excellent resistance to both wear and impact.

-

This makes it ideal for continuous operation in abrasive industrial environments.

Intelligent Control System

-

The system’s control unit can interface directly with conveyor belts.

-

This enables fully automated operation of the drum type magnetic separator.

-

It offers both manual control and centralized control modes for flexibility.

-

This permanent magnetic drum separator features a range of customizable parameters.

-

These parameters allow the system to be finely adapted to meet specific processing requirements.

Efficient Separation Performance

-

The equipment is specifically optimized for high-volume material processing.

-

This drum type magnetic separator effectively segregates magnetic from non-magnetic materials.

-

The permanent magnetic drum separator excels in demanding applications.

-

Key applications include slag processing and municipal/industrial waste sorting.

-

It is engineered to maintain reliable, continuous operation.

-

This capability is essential for integration into modern industrial processing lines.

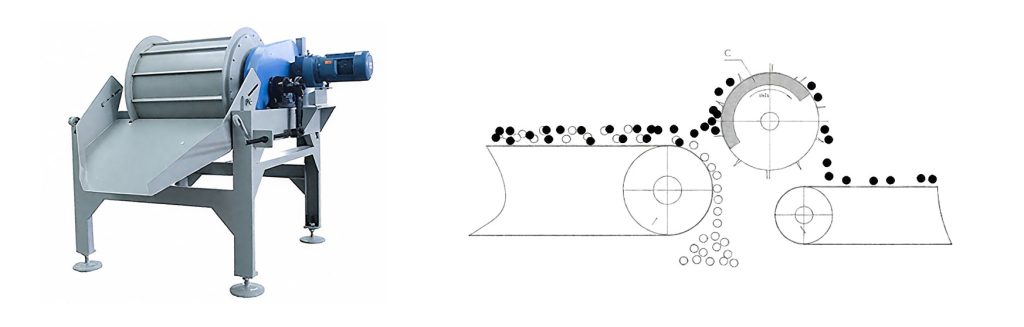

CTZS Upward Suction Permanent Drum Type Magnetic Separator Working Principle

Working Principle Overview

-

The CTZS permanent magnetic drum separator operates through the combined action of multiple forces.

-

Magnetic attraction and mechanical forces act on material particles simultaneously.

-

This efficient drum type magnetic separator creates distinct trajectories for different materials.

-

This separation occurs as materials pass through its effective magnetic field zone.

Magnetic Separation Process

-

When materials transport beneath the magnetic drum, ferrous contaminants are immediately extracted.

-

They are captured by the powerful, concentrated magnetic field.

-

This is the core function of the permanent magnetic drum separator.

-

The captured materials firmly adhere to the surface of the continuously rotating drum.

-

Meanwhile, non-magnetic particles continue their natural trajectory completely unaffected.

-

This precise separation is achieved by the advanced drum type magnetic separator system.

Material Discharge Mechanism

-

The drum’s continuous rotation transports the captured ferrous materials.

-

They are moved beyond the active magnetic field zone of the permanent magnetic drum separator.

-

Once beyond the magnetic influence, these materials discharge via gravitational force.

-

They fall into designated collection points or hoppers.

-

Non-magnetic materials exit the system through completely separate flow channels.

-

This reliable discharge mechanism is a key feature of the drum type magnetic separator.

Operational Advantages

-

This efficient, continuous separation process makes the CTZS permanent magnetic drum separator highly effective.

-

It is particularly suited for applications requiring continuous extraction of ferrous materials.

-

The system features efficient material handling and reliable discharge mechanisms.

-

These features ensure the optimal and consistent performance of this drum type magnetic separator.

-

The equipment is designed to perform reliably in various demanding industrial processing environments.

CTZS Upward Suction Permanent Drum Type Magnetic Separator Product Parameters

CTZS Upward Suction Permanent Drum Type Magnetic Separator Applications

Primary Application Fields

-

The CTZS drum type magnetic separator effectively recovers ferrous materials.

-

Its primary use is in steel slag processing and recycling operations.

-

This robust permanent magnetic drum separator serves waste sorting facilities.

-

It is used for metal recovery from municipal and industrial waste streams.

-

Scrap metal processors also utilize this equipment.

-

They use it for efficient material separation after shredding operations.

-

The system excels in high-capacity bulk processing applications.

-

These applications require continuous, automated ferrous metal extraction.

Specialized Application Conditions

-

This durable drum type magnetic separator performs reliably in challenging environments.

-

It is specifically designed to handle sharp and abrasive materials.

-

The permanent magnetic drum separator maintains consistent, high-level performance.

-

This is crucial in continuous, automated processing lines.

-

In such lines, equipment durability and uptime are paramount.

-

The system is engineered for high-volume ferrous removal.

-

It delivers exceptional reliability in the most demanding operational conditions.

System Integration

-

The equipment is fully compatible with standard belt conveyor systems.

-

This drum type magnetic separator enables continuous, in-line separation on moving belts.

-

The versatile permanent magnetic drum separator supports both stationary and mobile operations.

-

It integrates seamlessly with other separation equipment like eddy current separators or screens.

-

The system offers flexible configuration and mounting options.

-

This adaptability allows it to fit various plant layouts and meet specific processing requirements.

CTZS Upward Suction Permanent Drum Type Magnetic Separator Services

Categories

Categories