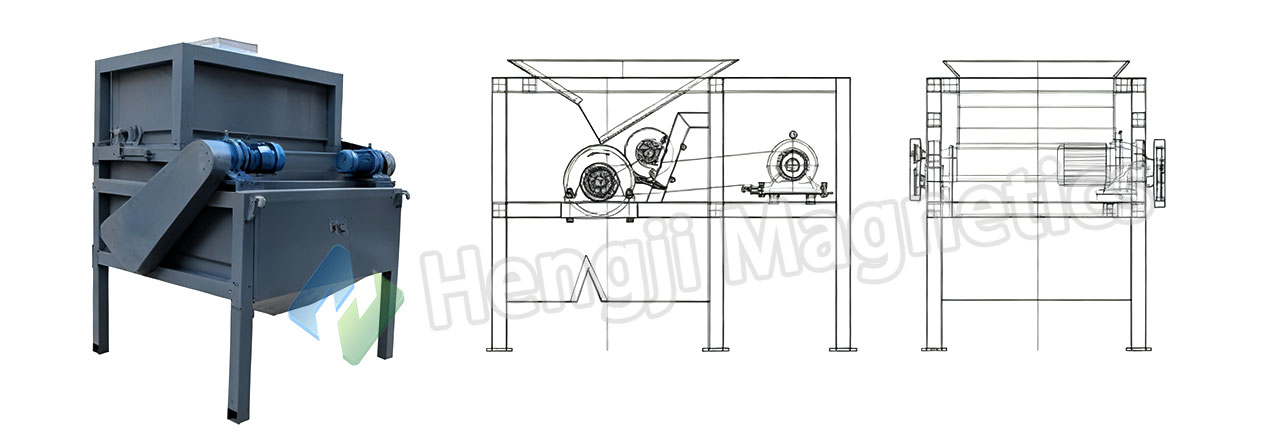

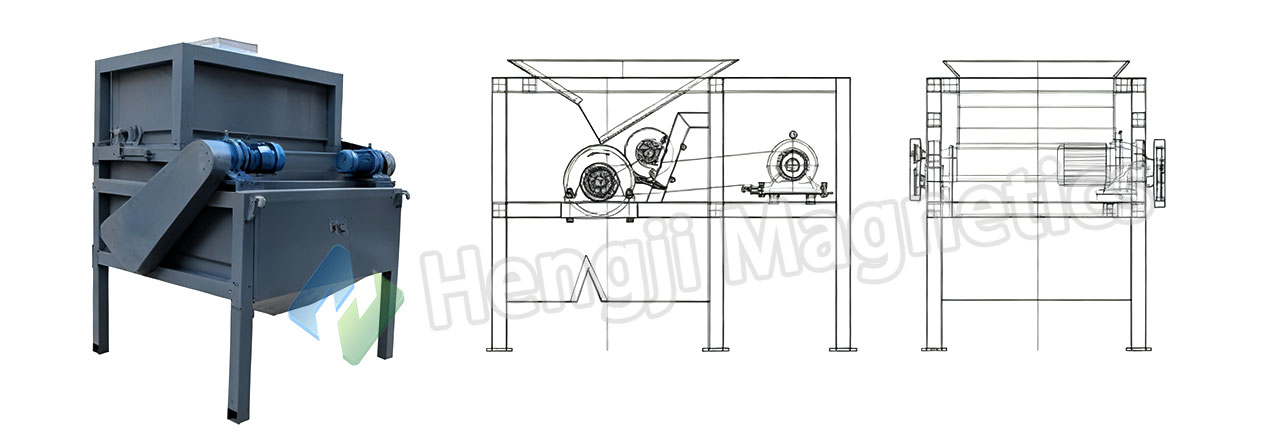

DHJ type strong Iron Ore Induced Roll Magnetic Separator Product Overview

The DHJ Series is a high-intensity induced roll magnetic separator. It utilizes advanced dry separation technology for powdered and granular materials.

This sophisticated iron ore magnetic separator uses rare-earth composite magnetic systems. It delivers exceptional magnetic strength and deep penetration.

It serves ceramics, mining, plastics, and chemical industries. This induced roll magnetic separator is also used in food processing.

Its robust construction ensures maximum separation efficiency and simple operation. Compliant with industry standards, this iron ore magnetic separator significantly improves product purity and recovery rates.

This induced roll magnetic separator is ideal for operations seeking enhanced product quality. It helps reduce processing costs effectively.

DHJ type strong Iron Ore Induced Roll Magnetic Separator Key Features

Advanced Magnetic System Design

-

This induced roll magnetic separator utilizes rare-earth composite magnetic rings.

-

It delivers both high magnetic intensity and extended penetration depth.

-

The system features high-strength adhesive bonding and optimized magnetic field distribution.

-

These elements ensure exceptional separation efficiency.

-

This makes the equipment a highly effective iron ore magnetic separator for diverse processing applications.

Optimized Structural Design

-

It features a modular design with configurable 1-10 layer arrangements.

-

This offers flexible adaptation for the induced roll magnetic separator to meet space constraints and specific processing needs.

-

The integrated system includes magnetic rolls, brush rolls, and robust frame assemblies.

-

This design provides strong performance with minimal maintenance requirements.

-

It enhances the versatility of this iron ore magnetic separator.

Efficient Transmission System

-

The system employs a reduction gear transmission with sprocket and chain connection.

-

This ensures exceptionally smooth operation of the induced roll magnetic separator.

-

Precision engineering minimizes operational vibration and noise.

-

Heavy-duty bearing assemblies are used to provide stable, reliable rotation.

-

These features guarantee the dependable performance of this iron ore magnetic separator.

Reliable Separation Performance

-

A specialized brush roll system is integrated into the induced roll magnetic separator.

-

This system thoroughly cleans captured magnetic materials from the roll surfaces.

-

This cleaning action significantly improves overall mineral recovery rates.

-

This efficient iron ore magnetic separator delivers consistent, high-quality results.

-

It performs reliably across various material types and a wide range of particle sizes.

-

The system ensures optimal separation performance in demanding conditions.

DHJ type strong Iron Ore Induced Roll Magnetic Separator Working Principle

Working Principle Overview

-

The DHJ series iron ore magnetic separator operates through an advanced multi-layer process.

-

This sophisticated induced roll magnetic separator utilizes high-intensity magnetic rolls.

-

The rolls extract ferrous contaminants as materials pass across their surfaces.

-

Magnetic particles are securely held against the continuously rotating rolls.

Magnetic Separation Process

-

The system features an innovative layered design, configurable from 1 to 10 layers.

-

It offers both single or paired magnetic roll arrangements.

-

This flexible design enables multiple separation stages within the iron ore magnetic separator.

-

The induced roll magnetic separator leverages the magnetic differences between various minerals.

-

Materials within the separator experience a combination of forces: magnetic, gravitational, and centrifugal.

-

Based on their magnetic properties, minerals follow different trajectories, achieving effective segregation.

Multi-Stage Separation Design

-

The progressive separation stages in the iron ore magnetic separator ensure thorough contaminant removal.

-

Captured magnetic materials are transported by the roll rotation to designated non-magnetic zones.

-

In these zones, specialized brush mechanisms integrated into the induced roll magnetic separator activate.

-

These brushes guarantee the complete discharge of all captured magnetic material.

-

This design maintains continuous, uninterrupted operation.

-

The system delivers optimal separation efficiency across a wide variety of material types and particle sizes.

DHJ type strong Iron Ore Induced Roll Magnetic Separator Product Parameters

DHJ type strong Iron Ore Induced Roll Magnetic Separator Applications

Primary Industry Applications

-

The DHJ induced roll magnetic separator serves a diverse range of industrial sectors.

-

These sectors include ceramics, mining, plastics, and chemical processing.

-

This versatile iron ore magnetic separator also provides essential support to other key industries.

-

These industries are pharmaceuticals, food processing, environmental protection, and metallurgy.

-

The system provides comprehensive and reliable iron removal solutions across a wide variety of material types.

Specific Application Scenarios

-

This high-performance induced roll magnetic separator effectively removes ferrous contaminants.

-

It processes various material forms, including powdered, flaky, and granular materials.

-

The equipment enables continuous, automatic iron removal directly within material processing lines.

-

This capability makes the iron ore magnetic separator an ideal solution for specific operational goals.

-

These goals include improving overall recovery rates and enhancing the final concentrate grade.

Process Advantages

-

The induced roll magnetic separator simplifies overall mineral processing circuits.

-

Its efficient operation significantly reduces long-term operational costs.

-

This efficient iron ore magnetic separator enhances economic returns for the plant.

-

This is achieved through demonstrable improvements in both product quality and mineral recovery.

-

The system offers fully customizable configurations.

-

It can be tailored to meet the precise purification requirements of various specific applications.

DHJ type strong Iron Ore Induced Roll Magnetic Separator Services

Categories

Categories