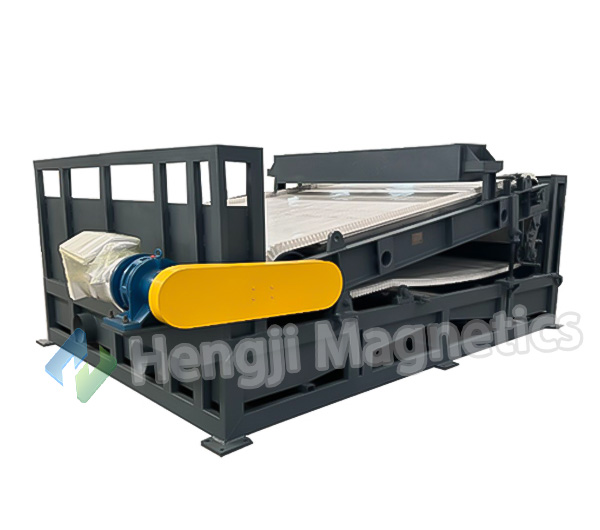

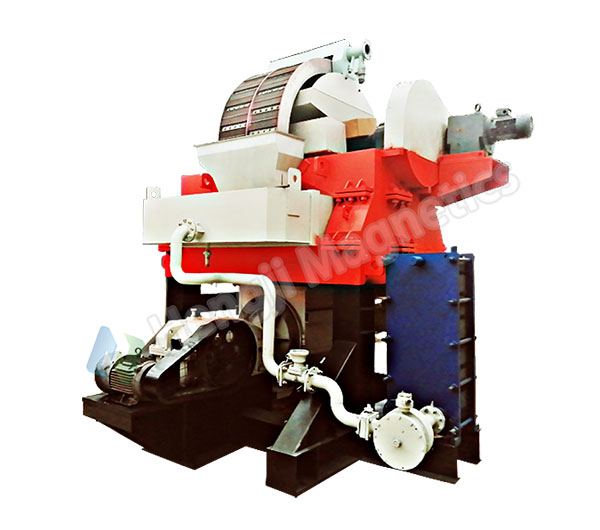

DCZ Fully Automatic Dry Electromagnetic Iron Separator Machine Product Overview

The DCZ Series is a high-performance electromagnetic separator machine. This dry electromagnetic separator is designed for powdered and granular materials.

Utilizing advanced electromagnetic technology, this electromagnetic iron separator delivers high magnetic field strength and flexible adjustability.

Ideal for chemical, building material, and food processing industries, the dry electromagnetic separator features a modular design and intelligent control.

It enables fully automated operation to improve material purity and protect downstream equipment. This electromagnetic separator machine has a robust construction for reliable performance.

The electromagnetic iron separator effectively enhances production efficiency. It provides stable and adaptive operation in diverse industrial environments.

DCZ Fully Automatic Dry Electromagnetic Iron Separator Machine Key Features

High-Efficiency Iron Removal

-

Uses high-performance electromagnetic coils

-

Generates magnetic field strengths exceeding 1.2T

-

Adsorbs micron-sized ferromagnetic impurities

-

This dry electromagnetic separator ensures thorough purification

-

The electromagnetic iron separator effectively cleans materials

Precise Adjustment Capability

-

Excitation current continuously adjustable

-

Adapts to different material characteristics

-

Enables precise iron removal

-

This electromagnetic separator machine features integrated vibration motor

-

Prevents material buildup

-

Improves separation efficiency

Intelligent Control System

-

PLC system monitors real-time parameters

-

Tracks magnetic field strength and current

-

Monitors temperature continuously

-

Supports remote operation

-

This dry electromagnetic separator has enclosed design

-

Requires minimal footprint

-

The electromagnetic iron separator integrates flexibly

Energy Efficiency and Durability

-

Uses high-efficiency silicon rectification technology

-

Reduces energy consumption significantly

-

Produces no pollution

-

Critical components made of stainless steel

-

Features wear-resistant materials

-

This electromagnetic separator machine ensures corrosion resistance

-

Provides long service life

Safety and Reliability

-

Includes over-current protection

-

Features over-temperature protection

-

Automatic alarm functions

-

Guarantees stable operation

-

This dry electromagnetic separator suits diverse environments

-

The electromagnetic iron separator ensures reliable performance

DCZ Fully Automatic Dry Electromagnetic Iron Separator Machine Working Principle

Operating Principle

-

DCZ dry electromagnetic separator uses electromagnetic induction

-

Excitation coil generates high-intensity magnetic field

-

Steel guide plates become magnetized

-

Forms strong magnetic working zone

-

This electromagnetic iron separator creates targeted separation area

Magnetic Field Generation

-

Energized coil produces magnetic field

-

Magnetizes steel plates effectively

-

Creates concentrated magnetic zone

-

This electromagnetic separator machine establishes powerful attraction

-

The dry electromagnetic separator forms optimal working area

Material Processing

-

Materials fed via vibrating conveyor

-

Enter magnetic separation zone

-

Ferromagnetic impurities are adsorbed

-

Captures iron powder and iron oxides

-

This electromagnetic iron separator attracts contaminants

-

The electromagnetic separator machine cleans materials effectively

Separation Process

-

Non-magnetic materials continue along path

-

Magnetic contaminants stay attached to plates

-

This dry electromagnetic separator ensures clean separation

-

The electromagnetic iron separator maintains material purity

Discharge System

-

Power cutoff triggers discharge

-

Magnetic field direction switching possible

-

Adsorbed impurities automatically released

-

This electromagnetic separator machine cleans itself

-

The dry electromagnetic separator automates waste removal

Vibration Control

-

Adjustable vibration system included

-

Ensures uniform material flow

-

Maintains consistent separation performance

-

This electromagnetic iron separator optimizes processing

-

The electromagnetic separator machine enhances efficiency

DCZ Fully Automatic Dry Electromagnetic Iron Separator Machine Product Parameters

DCZ Fully Automatic Dry Electromagnetic Iron Separator Machine Industry Applications

Chemical Industry Applications

-

Purifies plastic pellets effectively

-

Cleans rubber powder materials

-

Processes pigment purification

-

This dry electromagnetic separator ensures product quality

-

The electromagnetic iron separator serves chemical processing

Building Materials Applications

-

Removes iron impurities from quartz sand

-

Cleans ceramic powder materials

-

Processes cement raw meal

-

This electromagnetic separator machine protects equipment

-

The dry electromagnetic separator serves construction materials

Food Processing Applications

-

Separates metal contaminants from flour

-

Cleans starch materials

-

Processes sugar powder purification

-

This electromagnetic iron separator meets hygiene standards

-

The electromagnetic separator machine ensures food safety

Metallurgy and Recycling

-

Filters iron from metal powders

-

Cleans catalyst materials

-

This dry electromagnetic separator serves metallurgical operations

-

Enables ferrous metal recovery from e-waste

-

Processes industrial by-products

-

The electromagnetic iron separator supports recycling

Pharmaceuticals and Other Fields

-

Eliminates trace metals from medicinal powders

-

Serves precision processing of abrasives

-

Handles carbon black materials

-

Processes refractory materials

-

This electromagnetic separator machine serves specialized applications

-

The dry electromagnetic separator meets precision requirements

DCZ Fully Automatic Dry Electromagnetic Iron Separator Machine Services

Categories

Categories