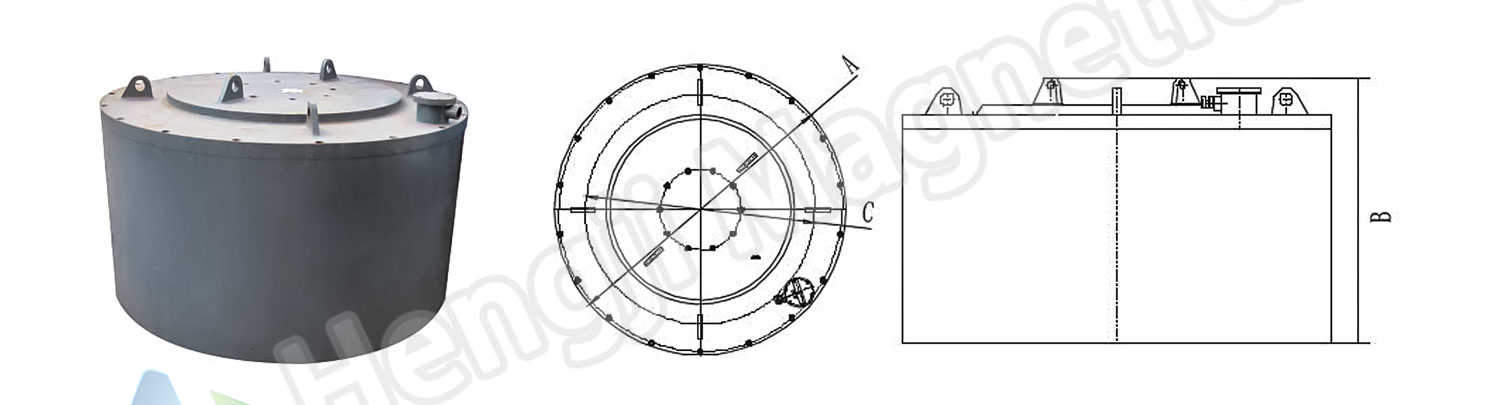

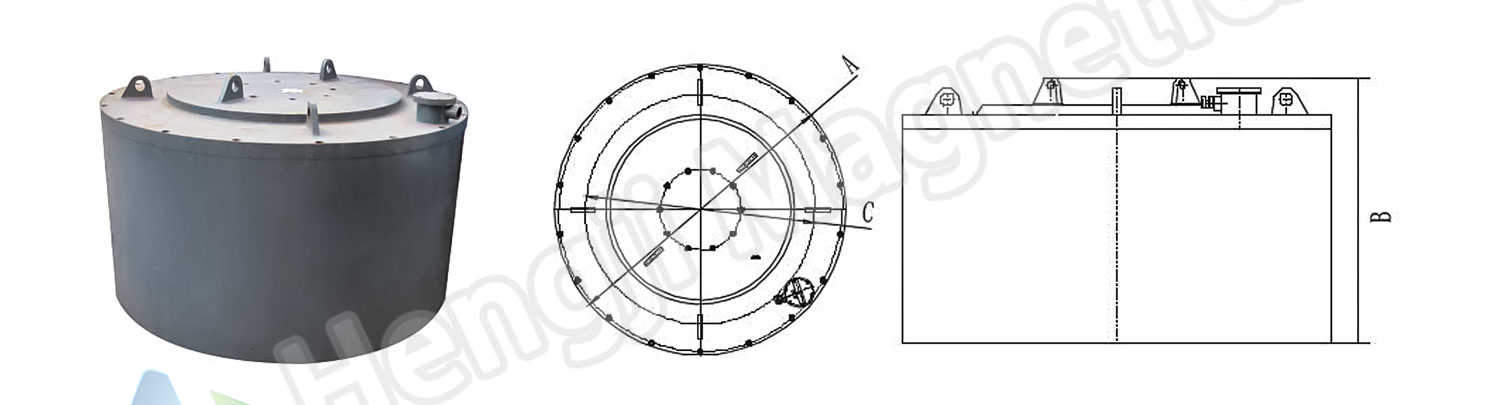

RBCDB Explosion-Proof Disc Iron Magnetic Separator Product Overview

The RBCDB series is a flame-proof electromagnetic separator. It is engineered for explosive gas and dust environments.

Certified with ExdI classification, this disc magnetic separator meets GB/T 3836.1-2010 standards. It is ideal for underground coal mines and chemical plants.

Featuring an optimized magnetic circuit, this iron magnetic separator delivers powerful force with low temperature rise.

It holds mining product safety certification. This disc magnetic separator ensures safe operation in methane and coal dust environments.

This iron magnetic separator is the preferred solution for hazardous condition iron removal.

RBCDB Explosion-Proof Disc Iron Magnetic Separator Key Features

xplosion-Proof Certification

-

ExdI mining flame-proof design

-

Features clear safety markings

-

Holds national certification

-

This disc magnetic separator meets strict safety standards

-

The iron magnetic separator suits hazardous environments

High Magnetic Strength

-

Uses high-performance magnetic circuit technology

-

Achieves maximum flux density up to 150mT

-

Removes ferrous objects (0.1-50kg)

-

This disc magnetic separator delivers powerful performance

-

The iron magnetic separator handles heavy contaminants

Efficient Cooling System

-

Incorporates advanced transformer technology

-

Features vacuum-encapsulated windings

-

Improves heat dissipation by 40%

-

This disc magnetic separator outperforms standard models

-

The iron magnetic separator maintains optimal temperature

Energy-Saving Design

-

Optimized magnetic circuit structure

-

Reduces power consumption by 30%

-

Noise levels ≤65dB

-

This disc magnetic separator saves energy

-

The iron magnetic separator is eco-friendly

Enhanced Safety & Durability

-

Double explosion-proof structure

-

IP65 protection rating

-

Class F insulation coils

-

Anti-corrosion treatment

-

This disc magnetic separator ensures reliability

-

The iron magnetic separator handles high humidity

Intelligent Control & Maintenance

-

Dedicated explosion-proof control cabinet

-

Provides real-time monitoring

-

Modular design enables quick replacement

-

This disc magnetic separator simplifies maintenance

-

The iron magnetic separator offers smart control

RBCDB Explosion-Proof Disc Iron Magnetic Separator Working Principle

Operating Principle

-

Works on electromagnetic induction

-

This disc magnetic separator uses excitation coils

-

The iron magnetic separator generates strong magnetic fields

Magnetic Field Generation

-

Rectification control system powers coils

-

Magnetic flux forms closed circuit

-

Creates high-gradient magnetic field

-

This disc magnetic separator establishes working gap

-

The iron magnetic separator produces intense magnetism

Separation Process

-

Ferrous contaminants become magnetized

-

Particles attracted to separator surface

-

Magnetic force captures iron effectively

-

This disc magnetic separator removes impurities

-

The iron magnetic separator handles non-magnetic materials

Continuous Removal System

-

Attached iron particles continuously removed

-

Uses auxiliary conveying equipment

-

Enables automatic operation

-

This disc magnetic separator provides continuous cleaning

-

The iron magnetic separator maintains production flow

Cooling System

-

Specialized thermal management system

-

Maintains coil temperature within limits

-

Ensures consistent performance

-

This disc magnetic separator handles extended operation

-

The iron magnetic separator manages heat efficiently

Performance Reliability

-

Efficient thermal management

-

Handles demanding applications

-

Maintains optimal magnetic performance

-

This disc magnetic separator ensures reliability

-

The iron magnetic separator delivers consistent results

RBCDB Explosion-Proof Disc Iron Magnetic Separator Product Parameters

RBCDB Explosion-Proof Disc Iron Magnetic Separator Critical Applications

Coal Mining Applications

-

Deployed in underground conveyor systems

-

Prevents equipment damage from tramp iron

-

This disc magnetic separator ensures operational safety

-

The iron magnetic separator protects mining environments

Chemical Industry Applications

-

Performs iron removal in explosive dust environments

-

Handles fertilizer and plastic pellet production

-

This disc magnetic separator complies with safety standards

-

The iron magnetic separator ensures process safety

Metallurgical Processing

-

Handles pre-treatment of mineral powders

-

Processes sintered materials at high temperatures

-

This disc magnetic separator supports efficient operations

-

The iron magnetic separator enables metallurgical processing

Power Generation Applications

-

Protects coal mills and crushers

-

Installed in coal handling systems

-

This disc magnetic separator maintains continuous operation

-

The iron magnetic separator ensures power generation

Building Materials Applications

-

Removes iron contamination from raw meal

-

Processes clinker conveying in cement production

-

This disc magnetic separator ensures product quality

-

The iron magnetic separator maintains material purity

Port Operations

-

Facilitates metal separation during loading/unloading

-

Enhances safety in port logistics

-

This disc magnetic separator handles bulk materials

-

The iron magnetic separator protects port equipment

Special Applications

-

Supports ceramic manufacturing

-

Serves glass production processes

-

This disc magnetic separator eliminates ferrous impurities

-

The iron magnetic separator ensures high-purity requirements

RBCDB Explosion-Proof Disc Iron Magnetic Separator Services

Categories

Categories