I. The Critical Need for Purity in New Energy

The Challenge: Minute ferrous impurities (iron particles, shavings) in battery materials like cathode powders (NMC, LFP, LCO), anode materials, lithium concentrates (spodumene), and electrolyte precursors can severely degrade electrochemical performance, cause safety hazards (internal shorts, thermal runaway), and lead to costly batch rejections.

Hengji’s Mission: To provide robust, reliable, and highly effective magnetic separation solutions specifically tailored to the unique particle size, flow characteristics, and sensitivity of new energy materials.

II. Targeted Solutions for Key Production Stages

Hengji offers a portfolio optimized for the stringent demands of lithium battery and new energy material manufacturing:

1.Ultra-Fine Dry Powder Purification:

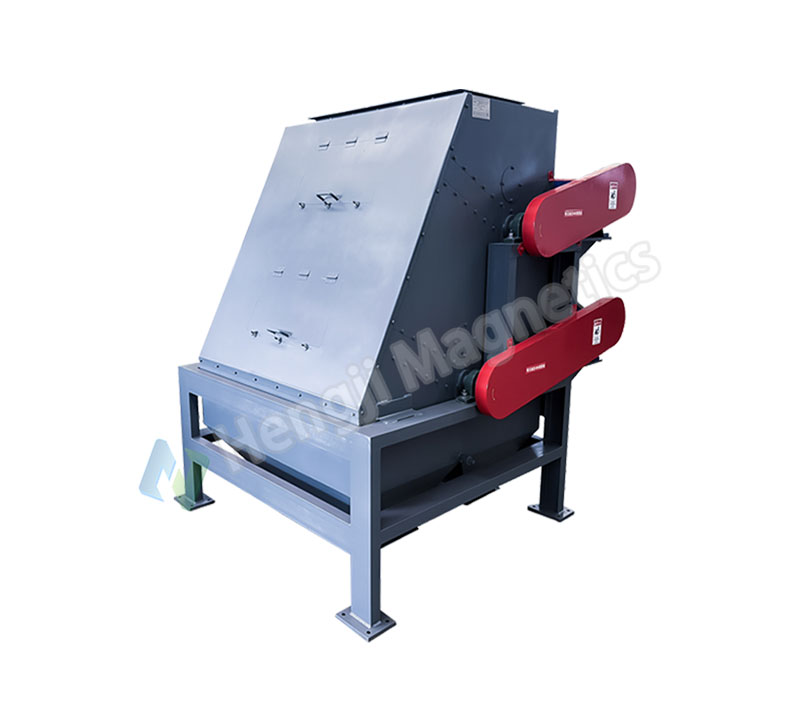

oSolution: High-Intensity Roll Magnetic Separators (CTQ Series).

oApplication: Continuous, automated removal of ferrous contaminants from sensitive cathode and anode powders (e.g., NMC, LFP, LCO, graphite) during processing and before cell assembly.

oImpact: Ensures exceptional purity of the active materials, maximizing energy density, cycle life, and safety of the final battery cell. Handles µm-sized powders efficiently with precise control.

2.Slurry & Liquid Stream Protection:

oSolution: Pipeline Magnetic Separators.

oApplication: In-line purification of slurry streams containing electrode materials or liquid precursors (e.g., electrolyte components) within closed pipeline systems.

oImpact: Prevents ferrous particles from contaminating sensitive slurries or liquids, protecting downstream coating equipment, mixers, and ensuring the integrity of the final coated electrodes or electrolyte formulation. Stainless steel construction ensures compatibility.

3.Raw Lithium Concentrate & Mineral Upgrading:

oSolution: High-Gradient Magnetic Separators (GTC Series).

oApplication: Pre-concentration and purification of weakly magnetic lithium-bearing minerals (e.g., spodumene) and other critical raw materials (e.g., manganese ores) prior to chemical processing.

oImpact: Effectively removes fine iron-bearing gangue minerals, improving the feed grade for hydrometallurgical processing, reducing acid consumption, waste generation, and overall production costs. Solves clogging issues common with fine particles.

III. Engineered for New Energy Excellence

Hengji solutions stand out through deep industry understanding and technical capability:

µm-Level Expertise: Proven experience and a comprehensive experimental database for effectively removing ferrous contaminants from micron and sub-micron powders and slurries common in battery material production.

Technology Agnostic Approach: Offering both high-performance Permanent Magnet and Electromagnetic solutions (e.g., RCDD Series) to best match specific material characteristics, process flow, and automation requirements.

Process Integration Focus: Designs (like Pipeline and Roll Separators) enable seamless integration into automated production lines, supporting 24/7 operation with minimal manual intervention.

Customization Driven by Data: Supported by a dedicated laboratory and expert team for material testing and solution optimization. Offers material trial services to validate performance before deployment.

Robust & Reliable: Built to maintain critical performance in demanding production environments, minimizing downtime.

IV. Tangible Benefits for New Energy Producers

Implementing Hengji magnetic separation delivers significant competitive advantages:

Enhanced Battery Performance & Safety: Achieves the ultra-low iron contamination levels essential for high energy density, long cycle life, and inherent safety in lithium-ion cells.

Reduced Production Risk: Minimizes the potential for costly batch contamination, rework, or rejection due to ferrous impurities.

Increased Process Yield: Optimizes the utilization of valuable raw materials by preventing contamination-related losses.

Lower Operating Costs: Reduces expenditure on consumables (e.g., acids in refining) and minimizes downtime associated with equipment damage or contamination events.

Protection of Sensitive Equipment: Safeguards precision mixers, coaters, calenders, and other downstream machinery from abrasive ferrous particles.

Faster Time-to-Market: Reliable purification enables stable, high-volume production to meet market demands.

Sustainability: Contributes to efficient resource use and reduces waste.

Partner with Hengji for the Foundation of Energy Innovation

In the race to power the future, material purity is non-negotiable. Hengji provides the essential, proven magnetic separation technology trusted by leading new energy material producers to safeguard their processes and products. From µm-scale powders to critical mineral concentrates, our solutions are engineered to meet the extreme purity demands of lithium battery manufacturing and beyond. Ensure the performance, safety, and efficiency of your next-generation energy materials. Contact Hengji today to explore how our tailored iron removal expertise can optimize your production.