Advanced Magnetic Separation for Mining and Mineral Processing

Hengji Magnetic & Electrical serves as a pivotal partner to the global mining industry, delivering advanced and reliable technology that enhances efficiency and profitability across mineral processing operations.

Our comprehensive equipment portfolio is engineered to support the entire processing circuit, from pre-concentration and roughing to cleaning and scavenging stages. We specialize in the efficient magnetic separation of minerals across a wide spectrum, handling materials from strongly magnetic to weakly magnetic, from coarse fragments to fine powders, in both dry and wet processing environments.

The core mission of our magnetic separation mining solutions is to enable operations to achieve higher concentrate grades, maximize recovery rates, and significantly reduce production costs. Our targeted equipment design makes modern magnetic separation mining processes more profitable and sustainable. We provide robust solutions for diverse challenges, from simple tramp iron removal to complex purification of weakly magnetic ores, establishing our technology as a cornerstone of efficient mineral processing plants worldwide.

I. Separation by Mineral Type: Comprehensive Coverage

Our technology is precisely engineered to address the specific magnetic properties of various ores, ensuring optimal recovery and grade in the magnetic separation of minerals. This targeted approach is fundamental to modern magnetic separation mining, maximizing efficiency across diverse mineralogical challenges.

1. Efficient Processing of Strongly Magnetic Minerals (e.g., Magnetite)

Core Equipment: The CTB Series Semi-Countercurrent Wet Drum Magnetic Separator is our flagship solution for processing strongly magnetic materials. This robust machine is expertly designed for the wet magnetic separation of minerals like magnetite, pyrrhotite, roasted ore, and ilmenite.

Application: It is predominantly deployed in the roughing and cleaning stages of magnetite concentration. The separator’s unique semi-countercurrent tank design, where feed slurry enters from the bottom and tailings are discharged counter-currently, creates an extended magnetic agitation path. This results in a high-grade concentrate while simultaneously minimizing metal losses to tailings, thereby guaranteeing high recovery rates. This machine is also critically employed in heavy media coal washing circuits for the highly efficient recovery of magnetite media.

2. Concentration and Purification of Weakly Magnetic Minerals (e.g., Manganese, Hematite, Wolframite)

Core Equipment: The QCG Series Strong Magnetic Roll Wet Separator and the GTC Series Plate-Type High-Gradient Magnetic Separator represent our advanced solutions for challenging, weakly magnetic ores.

Application:

The QCG Model features a multi-layer, strong magnetic roll design capable of multiple separation stages. It is exceptionally effective for the roughing, scavenging, and cleaning of fine-grained, weakly magnetic ores like manganese ore, hematite, limonite, and wolframite. As material passes over the successive rolls, a highly efficient and progressive separation occurs, significantly enhancing recovery rates in complex magnetic separation mining operations.

The GTC Model is a revolutionary product offering an intense magnetic field at a significantly lower operational cost than traditional high-gradient separators. It specifically solves the global industry challenge of matrix clogging when processing fine, weakly magnetic particles. It is ideal for purifying materials like quartz sand, feldspar, and fine iron ores, effectively elevating the final concentrate grade and ensuring the economic viability of the magnetic separation of minerals from low-grade deposits.

II. Separation by Process Stage: Covering the Entire Circuit

Our comprehensive equipment portfolio integrates seamlessly into every stage of the mineral processing flow, delivering optimized performance and efficiency throughout the magnetic separation mining circuit.

1. Pre-Beneficiation (Waste Discarding) Stage

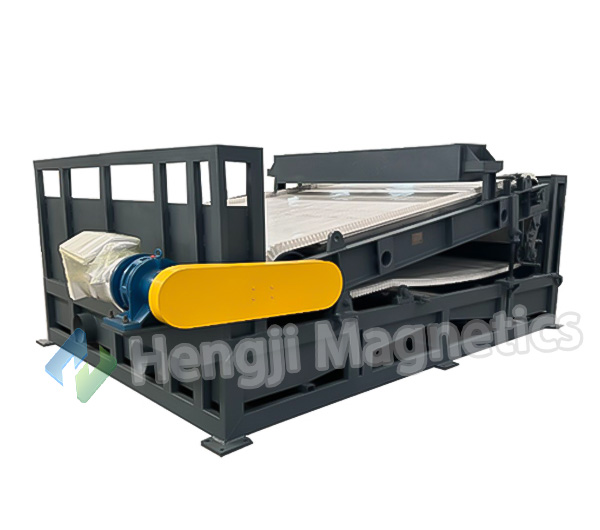

Core Equipment: HCG Series Coarse Ore Dry Magnetic Separators, RCT Series Permanent Magnet Drums.

Application: This critical initial phase focuses on pre-concentration before grinding to enhance overall plant efficiency. The HCG Dry Separator performs the magnetic separation of minerals in their natural state, pre-concentrating 0-12mm magnetite or dry powdery ores to discard substantial volumes of low-grade waste rock. This action significantly elevates the feed grade to the mill, drastically reducing grinding energy consumption and operational expenditures. The RCT Permanent Magnet Drum serves as an efficient conveyor head pulley, providing continuous tramp iron removal or initial enrichment directly during material transport, seamlessly integrating resource conservation into the material handling process.

2. Roughing and Scavenging Stages

Core Equipment: CTB, QCG, and CTN (Full Countercurrent) Series Wet Magnetic Separators.

Application: This phase forms the core of the magnetic separation mining process. The roughing stage performs the initial separation of run-of-mine or pre-concentrated ore to produce a crude concentrate. The subsequent scavenging stage treats the roughing tailings to maximize the recovery of any remaining valuable minerals, a crucial step for lowering the final tailings grade and minimizing resource waste. Our CTB and CTN magnetic separators can be flexibly configured in series or parallel to meet specific circuit requirements, ensuring that the magnetic separation of minerals is both thorough and cost-effective.

3. Cleaning Stage

Core Equipment: CTS Series Downstream Wet Magnetic Separators, CTB Series Separators.

Application: The final cleaning stage is dedicated to purity and quality. It processes the crude concentrate to remove middlings and residual impurities, producing a high-grade, marketable final product. By precisely adjusting magnetic field intensity, drum speed, and tank configuration, our separators achieve superior selectivity. The CTS Downstream model is particularly effective for cleaning coarser fractions, while CTB units are often deployed for secondary or tertiary cleaning, ensuring the concentrate meets the most stringent market specifications for the magnetic separation of minerals.