- Essential Defense: Protecting Product Quality & Process Integrity

- Core Function:Reliable removal of ferrous impurities (iron fragments, shavings, scale, fine particles) introduced through raw materials or processing.

- Critical Impact:

- Uncompromised Purity:Ensures chemical intermediates, final products, and ceramic bodies meet stringent quality standards by eliminating contamination that compromises performance, color, or clarity.

- Equipment Longevity:Prevents abrasive wear, jams, and catastrophic damage to sensitive machinery like pumps, reactors, mills, extruders, and spray dryers.

- Reduced Downtime & Waste:Minimizes production stoppages, costly rework, and batch rejection caused by metal-induced failures or product defects.

- Precision Solutions for the Chemical Industry

Hengji addresses the unique challenges of chemical processing:

- Liquid & Slurry Streams:

- Solution:Pipeline Magnetic Separators (CYG Series).

- Application:Continuous in-line purification of chemical solutions, polymer melts, pigment dispersions, dye baths, pharmaceutical intermediates, and catalyst slurries.

- Benefit:Efficiently captures ferrous particles within closed pipelines, preventing contamination of sensitive products and protecting downstream equipment. Constructed with corrosion-resistant stainless steel (SUS 304 / SUS 316L) for compatibility with aggressive media. Flange or clamp connections ensure secure integration.

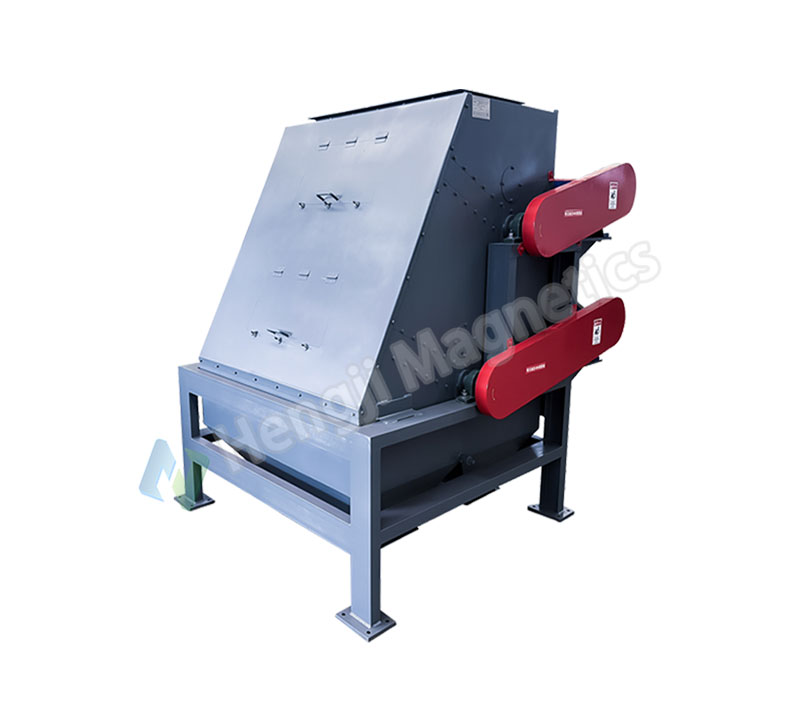

- Powdered & Granular Materials:

- Solution:Automatic Cleaning Magnetic Separators (CQZ Series).

- Application:Protecting processes handling plastic pellets, rubber compounds, powdered chemicals, catalysts, pigments, and additives.

- Benefit:Pneumatic self-cleaning mechanism removes captured tramp metal without interrupting production flow, ideal for high-volume powder handling systems. Ensures contaminant-free feed to mixers, reactors, and packaging lines.

III. Specialized Purification for Ceramic Excellence

Hengji solutions are vital for achieving defect-free ceramics:

- Raw Material Preparation:

- Solution:Vertical Pipeline Magnetic Separators (RCYZ Series), Permanent Magnetic Drums (RCT Series), Plate Magnets.

- Application:Removing iron contamination from critical ceramic ingredients: quartz sand, feldspar, kaolin, alumina, zirconia, and glaze powders/slurries.

- Benefit:Prevents tiny iron particles from causing unsightly black spots, pinholes, or weakening during firing. High-intensity conical magnetic fields (RCYZ) are particularly effective for powders and small granules directly fed from hoppers or conveyors. Plate magnets excel in gravity-fed chutes for granular materials.

- Slip & Glaze Processing:

- Solution:Pipeline Magnetic Separators (CYG Series).

- Application:Final purification of ceramic slurries and glaze suspensions before casting or spraying.

- Benefit:Ensures flawless surface finish by removing the last traces of ferrous contaminants that could mar the final fired product.

- Universal Advantages for Demanding Industries

Hengji equipment is engineered for performance and reliability:

- High-Efficiency Separation:Utilizes powerful Neodymium Iron Boron (NdFeB) permanent magnets, delivering strong magnetic fields for thorough contaminant removal without external power consumption.

- Robust & Hygienic Construction:Premium stainless steel (SUS 304 / SUS 316L) ensures corrosion resistance, durability, and suitability for demanding chemical environments and clean ceramic production.

- Simple Operation & Low Maintenance:Minimal moving parts and straightforward design. Requires only periodic cleaning of captured metal to maintain peak performance. Automatic cleaning options (CQZ) further reduce manual intervention.

- Environmentally Sound:Zero energy consumption and no chemical additives, contributing to sustainable manufacturing.

- Tangible Results for Manufacturers

Implementing Hengji magnetic separation delivers measurable benefits:

- Superior Product Quality:Eliminates ferrous contamination, ensuring consistent color, clarity, strength, and performance of chemicals and defect-free ceramic finishes.

- Reduced Production Costs:Minimizes scrap, rework, and batch losses due to contamination or equipment damage.

- Extended Equipment Life:Protects pumps, valves, nozzles, grinding media, kiln furniture, and forming equipment from abrasive wear and impact damage.

- Enhanced Process Reliability:Prevents unplanned downtime caused by metal jams or component failures.

- Optimized Efficiency:Automated cleaning systems support continuous, high-volume production.

- Sustainable Operations:Recovers valuable materials (metal), reduces waste, and lowers energy consumption.

Partner with Hengji for Flawless Production

In industries where purity defines success, Hengji provides the critical barrier against ferrous contamination. Our reliable, efficient, and corrosion-resistant magnetic separators are trusted by leading chemical producers and ceramic manufacturers to protect their products, processes, and profitability. Achieve the highest standards of quality and operational efficiency. Contact Hengji today to discover the optimal iron removal solution for your chemical or ceramic application.