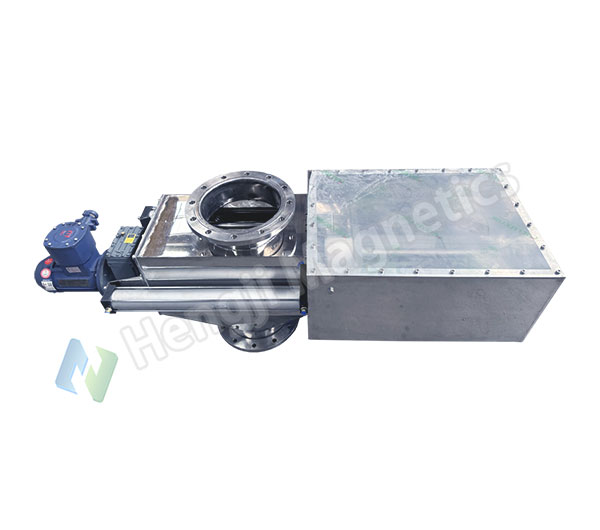

CBZ Automatic Rotary Magnet Magnetic Separator Product Overview

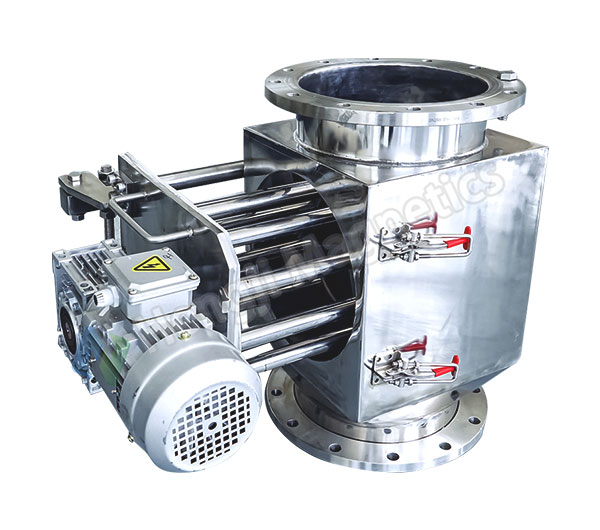

The CBZ series represents a significant advancement in magnetic separation technology with its innovative rotating system that achieves full automation in iron removal processes. This advanced rotary magnetic separator utilizes a unique magnetic arrangement and rotational operation to significantly enhance both efficiency and automation levels.

Featuring a multi-layer magnetic configuration with precisely calculated spacing, this rotary magnet system ensures optimal magnetic field utilization. The compact design and sophisticated magnetic circuit maximize strong magnetic zone utilization while maintaining low energy consumption. With applications spanning food processing, ceramics, chemicals, mining, and electronics industries, this rotary magnetic separator establishes new standards for automated magnetic separation in modern production environments.

CBZ Automatic Rotary Magnet Magnetic Separator Key Features

Innovative Magnetic System Design

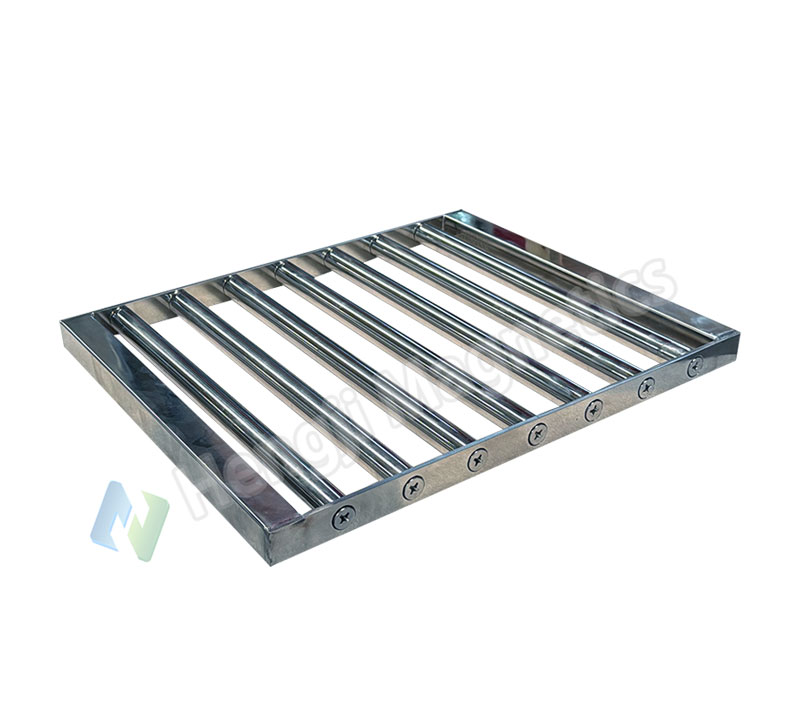

The rotary magnetic separator features a rotating magnetic assembly with precisely calculated rod spacing and multi-layer configuration. This advanced rotary magnet system utilizes high-performance NdFeB materials and unique magnetic circuit design, improving strong magnetic zone utilization by over 40% for enhanced separation efficiency.

High-Efficiency Separation Performance

Achieving over 99.5% efficiency for iron powders and fine particles, this rotary magnetic separator handles 0.5-10 tons per hour. The fully automated rotary magnet ensures complete material exposure to magnetic fields through special arrangement, requiring no manual intervention during operation.

Intelligent Control System

Programmable controllers enable parameter adjustments based on material characteristics in this rotary magnetic separator. The rotary magnet features variable frequency speed control, automatic alarm monitoring, and self-diagnostic functions for precise operation and easy maintenance.

Robust Structural Design

Constructed with stainless steel for corrosion resistance, this rotary magnetic separator provides excellent sealing to prevent dust leakage. The precision reduction motor and modular design ensure reliable operation and simplified maintenance for this durable rotary magnet system.

CBZ Automatic Rotary Magnet Magnetic Separator Working Principle

The CBZ rotary magnetic separator operates through dynamic magnetic field adsorption, creating an efficient automated separation process for continuous production environments.

Magnetic Separation Process

When activated, the rotary magnet system begins slow rotation as materials enter uniformly through the inlet. The rotating magnetic assembly generates a dynamically changing field that subjects ferrous contaminants to alternating magnetic forces. This advanced rotary magnetic separator effectively extracts and holds ferrous particles on the magnetic rod surfaces while non-magnetic materials pass through unaffected by gravity.

Automatic Cleaning Operation

The continuous rotation of this rotary magnet transports captured contaminants away from the working zone to dedicated discharge positions. As the rods reach specific locations, automatic cleaning mechanisms activate to remove accumulated ferrous materials. This sophisticated rotary magnetic separator maintains uninterrupted operation through programmed intermittent cleaning cycles.

Automated Production Integration

The entire process – feeding, separation, discharge, and cleaning – operates fully automatically in this rotary magnet system. The intelligent programming enables continuous operation without production stoppages, making this rotary magnetic separator particularly valuable for modern production lines where efficiency and automation are paramount.

CBZ Automatic Rotary Magnet Magnetic Separator Product Parameters

Standard diameter (mm): 150, 200, 250, 300, 350, 400, 450, 500. Can be customized according to customer’s on-site requirements.

CBZ Automatic Rotary Magnet Magnetic Separator Applications

Industry Applications

The rotary magnetic separator provides essential purification in food processing for flour, starch, and milk powder. This efficient rotary magnet serves chemical industries by removing iron from plastic pellets and pigments, while ceramic manufacturers utilize it for glaze and kaolin purification. The equipment also processes non-metallic minerals and electronic materials, demonstrating the rotary magnetic separator‘s versatility across multiple precision industries.

Material Specifications

This advanced rotary magnet handles dry powders and fine granular materials within 100-400 mesh particle size ranges. The rotary magnetic separator operates effectively in environments from -20℃ to 40℃, processing materials with humidity not exceeding 5% to maintain optimal separation performance and equipment reliability.

Typical Application Scenarios

The rotary magnet performs in-line purification within powder conveying systems and provides feed inlet protection against iron contamination. This versatile rotary magnetic separator ensures final product purity before packaging and enhances recycled material quality, offering automated solutions for various processing stages where consistent ferrous removal is critical.

CBZ Automatic Rotary Magnet Magnetic Separator Services

Technical Consultation

We provide complimentary sample testing and customized solutions for the rotary magnetic separator. Our experts conduct on-site assessments and offer equipment selection guidance, ensuring optimal integration of the rotary magnet into your production line through regular technical exchanges.

Installation Support

Detailed installation drawings and technical parameters ensure proper setup of your rotary magnetic separator. Professional engineers supervise installation while providing commissioning services and operator training for the rotary magnet system.

After-Sales Support

Our 18-month warranty includes lifelong maintenance for the rotary magnetic separator. We maintain customer records with regular follow-ups, 24/7 technical support, and strategic spare parts inventory to keep your rotary magnet operating efficiently.

Upgrade Services

Performance enhancements and functional modifications adapt the rotary magnetic separator to process changes. We provide relocation services and regular optimization recommendations to maximize benefits from your rotary magnet investment.

Training & Knowledge Transfer

Comprehensive operation manuals and regular training programs support your rotary magnetic separator. Online tutorials and user exchange platforms enhance operational knowledge of the rotary magnet system.

Categories

Categories