CGB Permanent Rotating Magnet Magnetic Field Separator Product Overview

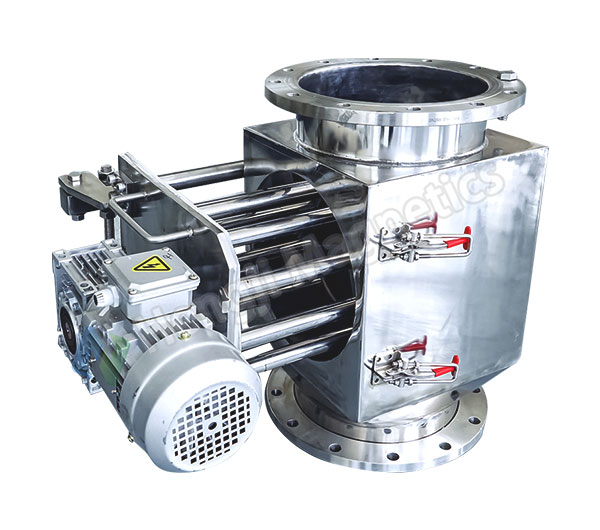

The CGB series semi-automatic magnetic rod separator introduces a significant innovation for processing powdery, granular, and easily agglomerated materials. This advanced rotating magnet system effectively resolves common clogging issues through its unique motor-driven rotating magnetic rod design. The equipment’s modular construction and flexible configuration make it ideal for chemical, food, pharmaceutical, and building materials industries.

Utilizing high-performance NdFeB magnets, this permanent rotating magnetic field separator delivers exceptional magnetic strength with operational simplicity. The semi-automatic cleaning ensures consistent performance with minimal intervention. The rotating magnet design prevents material buildup through dynamic magnetic fields, making this permanent rotating magnetic field separator particularly effective for challenging applications with varying material characteristics.

CGB Permanent Rotating Magnet Magnetic Field Separator Key Features

Anti-Clogging Design Innovation

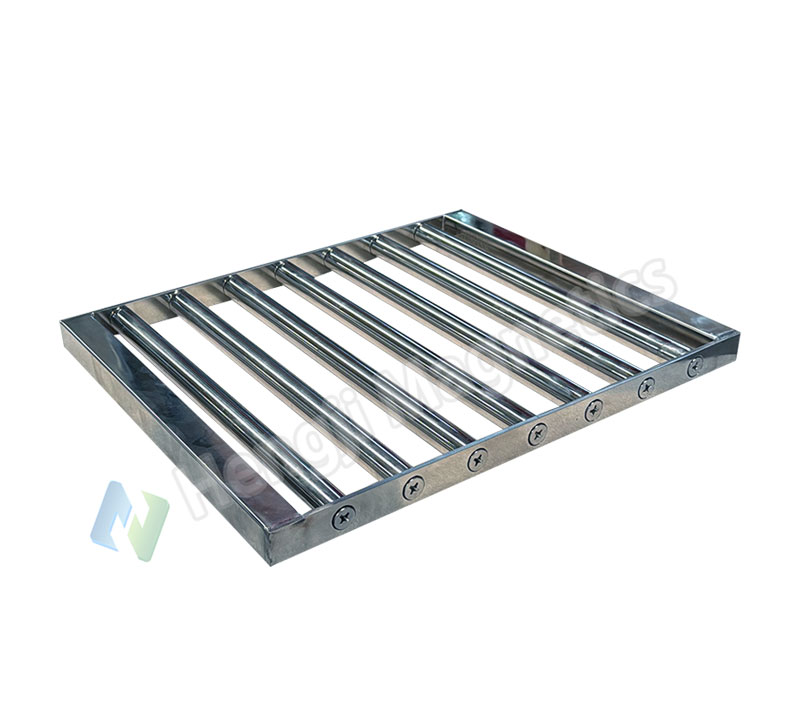

The motor-driven rotating magnet system prevents material adhesion through continuous rod rotation. This innovative permanent rotating magnetic field separator features special surface treatments and optimized magnetic rod arrangements that minimize material buildup while ensuring complete exposure to magnetic fields, maintaining consistent flow and separation efficiency.

Powerful Magnetic System

Utilizing high-performance NdFeB magnets, this rotating magnet delivers surface strength exceeding 12,000 Gauss. The multi-layer rod configuration creates gradient magnetic fields in this permanent rotating magnetic field separator, with computer-optimized circuits providing deep penetration to capture ferrous contaminants from micron to millimeter scale.

Flexible Configuration Options

Available in multiple diameters (150-500mm) with custom options, this rotating magnet adapts to various installations including free-fall and pipeline applications. The permanent rotating magnetic field separator features adjustable rotation speeds and modular design, accommodating different material characteristics and space constraints.

Reliable Performance Characteristics

With IP65 protection and corrosion-resistant stainless steel construction, this rotating magnet withstands harsh environments. The low-power motor ensures quiet operation, while robust construction guarantees long-term reliability for this permanent rotating magnetic field separator with minimal maintenance requirements.

CGB Permanent Rotating Magnet Magnetic Field Separator Working Principle

The CGB separator operates through an integrated system of permanent magnetic attraction and dynamic mechanical cleaning, providing efficient ferrous separation for challenging materials.

Magnetic Separation Process

As materials containing ferrous contaminants pass through the separator, the rotating magnet system generates a dynamic magnetic field that effectively captures iron particles. The continuous rotation of magnetic rods (typically 5-15 rpm) in this permanent rotating magnetic field separator ensures thorough exposure of all material to the magnetic field, extracting contaminants from the material stream and securely holding them on the rod surfaces.

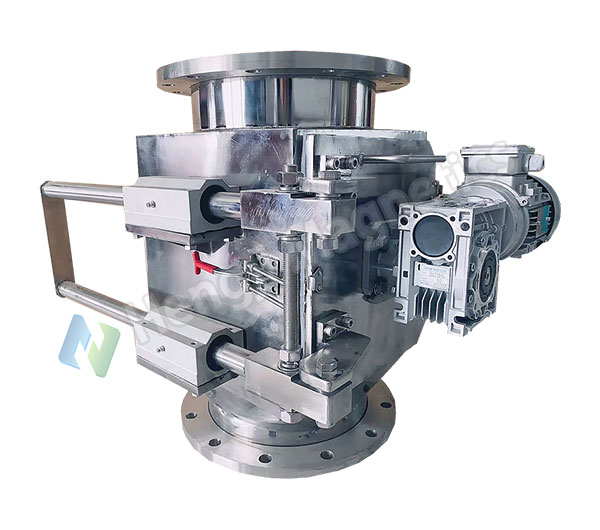

Dynamic Cleaning Mechanism

The rotating magnet transports captured materials to designated non-working zones where reduced magnetic strength and centrifugal force facilitate partial automatic discharge. For remaining contaminants, this permanent rotating magnetic field separator employs semi-automatic cleaning through simple manual operation that quickly removes accumulated metals without requiring complex disassembly procedures.

Anti-Clogging Advantage

The relative motion between material flow and rotating rods in this rotating magnet prevents material buildup, making the permanent rotating magnetic field separator particularly effective for sticky, agglomerating materials that typically challenge conventional separation systems, ensuring consistent performance in demanding applications.

CGB Permanent Rotating Magnet Magnetic Field Separator Applications

Industry Applications

The rotating magnet system provides essential purification in chemical processing for plastic pellets, pigments, and fertilizers. This efficient permanent rotating magnetic field separator serves food processing by removing iron from flour, starch, and milk powder, while pharmaceutical manufacturers utilize this rotating magnet for active ingredient purification. The equipment also processes building materials and supports recycling operations, demonstrating exceptional versatility across multiple industrial sectors.

.jpg)

Material Specifications

This advanced permanent rotating magnetic field separator handles particle sizes from 10-500 mesh fine powders to 6mm+ large particles. The rotating magnet effectively processes dry powders, granular materials, and flakes, with special suitability for easily agglomerated and adhesive materials. Processing capacities range from 0.5-20 tons per hour across different models of this permanent rotating magnetic field separator.

Typical Application Scenarios

The rotating magnet provides feed inlet protection against iron contamination in production systems. This versatile permanent rotating magnetic field separator performs in-line purification within conveying systems and ensures final product quality before packaging. The rotating magnet also enhances recycled material quality, offering comprehensive solutions for various processing stages where reliable ferrous separation is required.

CGB Permanent Rotating Magnet Magnetic Field Separator Services

Customized Engineering Solutions

We provide personalized design adaptations for the rotating magnet to address space constraints and layout challenges. Our engineers optimize magnetic circuits for specific materials and deliver complete system solutions for the permanent rotating magnetic field separator, including complementary equipment selection and integration planning.

Professional Installation Guidance

Detailed foundation drawings and pipeline diagrams ensure proper installation of your rotating magnet. We supervise equipment leveling and concentricity adjustments while providing integration support to seamlessly incorporate the permanent rotating magnetic field separator into existing production lines.

Comprehensive Operation Training

On-site training covers operational procedures and safety protocols for the rotating magnet. We demonstrate proper cleaning techniques and maintenance planning for the permanent rotating magnetic field separator, ensuring your team can effectively manage daily operations and record-keeping.

After-Sales Technical Support

Our 24-month quality assurance includes rapid response technical guidance for the rotating magnet. Regular performance evaluations and optimization recommendations maintain your permanent rotating magnetic field separator at peak efficiency, supported by guaranteed spare parts inventory and equipment upgrade services.

Categories

Categories

.jpg)