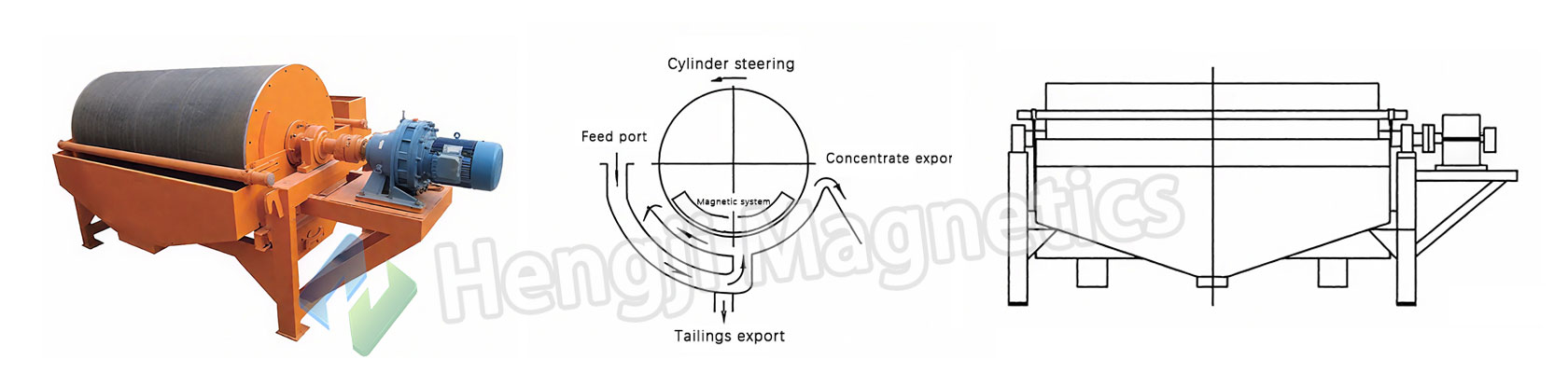

CTB Semi Countercurrent Ore Wet Permanent Magnetic Drum Separator Product Overview

The CTB Series is a semi-countercurrent wet permanent magnetic drum separator. It is designed for processing fine-grained ferromagnetic materials.

Featuring a sophisticated semi-countercurrent tank, this ore magnetic separator enhances efficiency and prevents clogging.

Its permanent magnetic system delivers consistent performance without external power. This wet permanent magnetic drum separator is ideal for various mineral processing applications.

It handles materials from 0.1-3mm particle size. The stainless steel drum of this ore magnetic separator ensures reliability in demanding environments.

This wet permanent magnetic drum separator effectively processes magnetic iron ore, pyrrhotite, and titanium iron ore. It is the preferred choice for high concentrate grade and superior recovery rates.

CTB Semi Countercurrent Ore Wet Permanent Magnetic Drum Separator Key Features

Advanced Magnetic System Design

-

Utilizes a rare-earth composite magnetic system secured with high-strength adhesive and epoxy resin.

-

Features stainless steel reinforcement and optimized magnetic field distribution.

-

This wet permanent magnetic drum separator maintains a minimal distance (≤4mm) between the drum and the magnetic system.

-

This design enhances the capture efficiency of the ore magnetic separator.

Optimized Tank Structure

-

Incorporates a specially designed semi-countercurrent tank.

-

This design in the wet permanent magnetic drum separator prevents material blockage and spillage.

-

Features a rational slurry flow direction and an adjustable gap between the tank and drum.

-

This makes the ore magnetic separator adaptable to varying processing capacities.

-

The structure significantly improves overall mineral recovery rates.

Reliable Transmission System

-

Offers flexible left or right transmission configurations for installation versatility.

-

Features a cycloidal reducer with chain wheel transmission for exceptionally smooth operation.

-

The direct vulcanized rubber drum surface provides a service life of 2-3 years.

-

This robust construction ensures the wet permanent magnetic drum separator withstands continuous operation.

-

The ore magnetic separator is built to perform reliably in harsh industrial environments.

Flexible Operational Adjustments

-

The magnetic system deflection angle is adjustable via a threaded rod mechanism.

-

This feature in the wet permanent magnetic drum separator enables precise process optimization.

-

The concentrate pipe pressure is also adjustable for fine-tuning.

-

Customizable operating parameters allow for adaptation to different mineral characteristics.

-

This high level of adjustability makes the ore magnetic separator exceptionally versatile for diverse applications.

CTB Semi Countercurrent Ore Wet Permanent Magnetic Drum Separator Working Principle

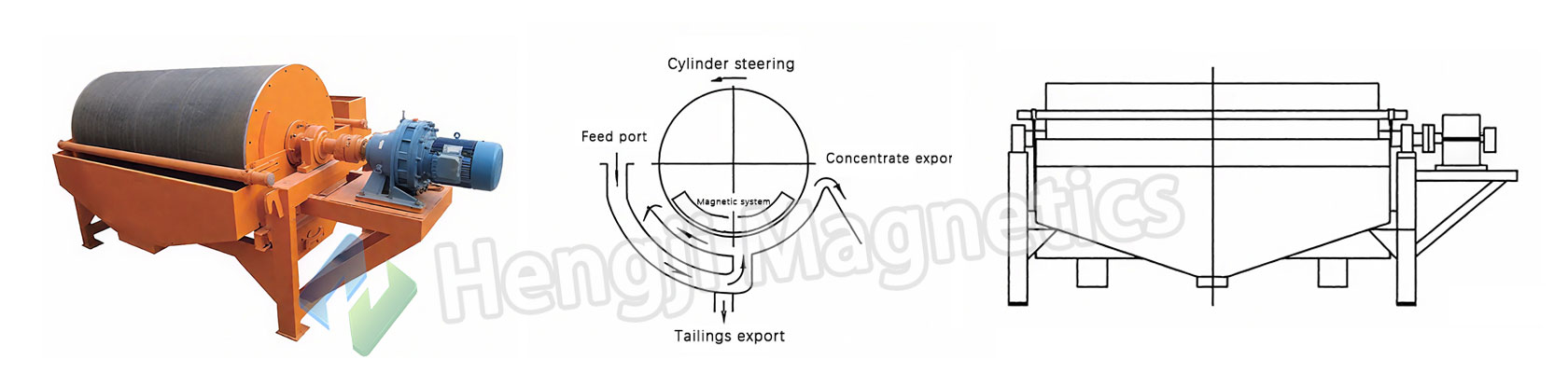

Working Principle Overview

-

The CTB ore magnetic separator operates through an advanced wet magnetic separation process.

-

Slurry enters the system through flange connections into the feed box.

-

Initial dilution occurs within the feed box.

-

The material is then evenly distributed across the rotating drum surface of the separator.

Magnetic Separation Process

-

Under the powerful magnetic field generated by the wet permanent magnetic drum separator, ferromagnetic particles are extracted from the slurry.

-

These extracted particles firmly adhere to the rotating drum surface.

-

The drum’s continuous rotation transports the captured magnetic materials to the concentrate discharge zone.

-

Meanwhile, non-magnetic particles continue their flow and exit through separate tailings outlets.

-

This process is the core function of the ore magnetic separator.

Automated Discharge System

-

The ore magnetic separator utilizes strategically placed high-pressure water sprays.

-

These sprays efficiently flush and discharge the concentrated materials into dedicated collection systems.

-

The wet permanent magnetic drum separator allows for precise adjustment of the magnetic system deflection angles.

-

Flushing pressure can also be finely tuned to match specific mineral characteristics.

-

This precise control ensures optimal mineral recovery rates and final product grade quality.

-

The entire system supports continuous, high-volume processing operations with minimal downtime.

CTB Semi Countercurrent Ore Wet Permanent Magnetic Drum Separator Product Parameters

CTB Semi Countercurrent Ore Wet Permanent Magnetic Drum Separator Applications

Primary Application Fields

-

The wet permanent magnetic drum separator effectively processes ferromagnetic materials, including:

-

Magnetic iron ore

-

Pyrrhotite

-

Ilmenite

-

This versatile ore magnetic separator performs critical iron removal operations for:

-

Coal

-

Non-metallic minerals

-

Building materials

-

The equipment also enables high-precision magnetic medium recovery in:

Special Process Applications

-

For enhanced tailings reprocessing, the wet permanent magnetic drum separator utilizes efficient double-drum configurations to maximize recovery rates.

-

This high-performance ore magnetic separator is essential for recovering magnetic materials such as iron and ferrosilicon in dense medium separation circuits.

-

It serves complex mineral processing flowsheets that require simultaneous improvements in both final product grade and overall recovery yield.

-

The system is designed to minimize valuable mineral losses during processing.

Process Benefits

-

The wet permanent magnetic drum separator significantly improves overall mineral recovery rates through its precise and efficient separation mechanism.

-

This reliable ore magnetic separator consistently enhances the quality of the final concentrate.

-

A key benefit is the effective reduction of valuable minerals lost to tailings.

-

The system simplifies overall processing circuits, leading to more streamlined operations.

-

These combined advantages lower operational and processing costs.

-

Ultimately, the equipment delivers substantially improved economic returns across a wide range of mineral processing applications.

CTB Semi Countercurrent Ore Wet Permanent Magnetic Drum Separator Services

Installation & Commissioning

-

We provide detailed, step-by-step installation guidance for the wet permanent magnetic drum separator.

-

Our standards ensure critical installation metrics, such as frame levelness ≤2mm, are strictly met.

-

Comprehensive system testing includes both no-load and load operations for thorough verification.

-

Our technicians perform critical parameter adjustments, focusing on tank-drum gap optimization.

-

This meticulous approach is designed to maximize the performance and efficiency of your ore magnetic separator.

Operation Training

-

We deliver complete operational procedure training for the entire wet permanent magnetic drum separator system.

-

Our training covers all aspects of routine maintenance and provides clear guidance for daily operations.

-

We equip your team with effective troubleshooting methodologies for common and complex issues.

-

The goal is to ensure the safe, reliable, and efficient long-term operation of your ore magnetic separator.

-

All training is based on established industry best practices.

Maintenance Support

-

Our structured maintenance program for the wet permanent magnetic drum separator is designed for reliability.

-

It includes mandatory monthly bearing lubrication to prevent wear.

-

Comprehensive six-monthly reducer servicing is performed to ensure smooth transmission.

-

We provide and manage a preventive maintenance schedule tailored to your operation.

-

This proactive approach safeguards your investment and ensures the long-term reliability of your ore magnetic separator.

Spare Parts Supply

-

We guarantee the availability of 100% genuine spare parts for the wet permanent magnetic drum separator.

-

Our support system ensures rapid technical response to any operational inquiries or issues.

-

We provide clear identification and sourcing for all critical wear parts.

-

This comprehensive parts and support system is crucial for maintaining the peak operational efficiency of your ore magnetic separator.

-

Our service minimizes downtime and protects your production continuity.

Categories

Categories