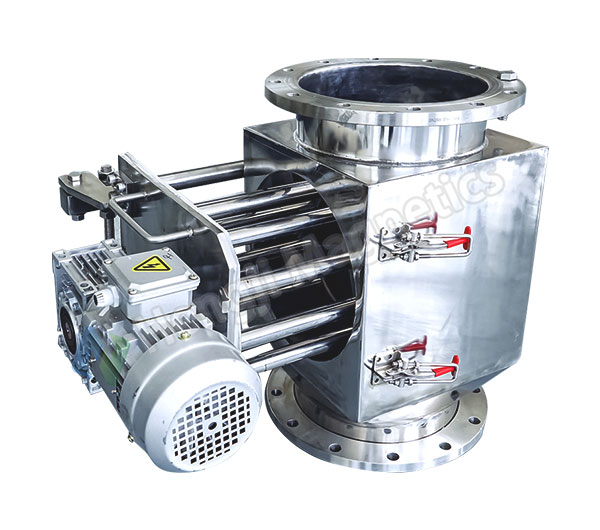

CYG Liquid Trap Magnet Separator Product Overview

The CYG series pipeline magnetic separator represents advanced permanent magnetic technology for extracting ferrous contaminants from liquids, slurries, and powders. This high-efficiency liquid magnetic separator features a pipeline design for direct system integration without disrupting processes. Utilizing rare-earth neodymium magnets, it delivers reliable performance as an effective liquid trap for metallic contaminants.

Operating without external power, this innovative trap magnet offers significant energy savings and minimal maintenance. The robust construction and flexible configurations make this liquid magnetic separator ideal for operations requiring high purity standards. ISO9001 certified and compliant with international standards, the CYG series serves as a preferred liquid trap solution for quality-focused global operations.

CYG Liquid Trap Magnet Separator Key Features

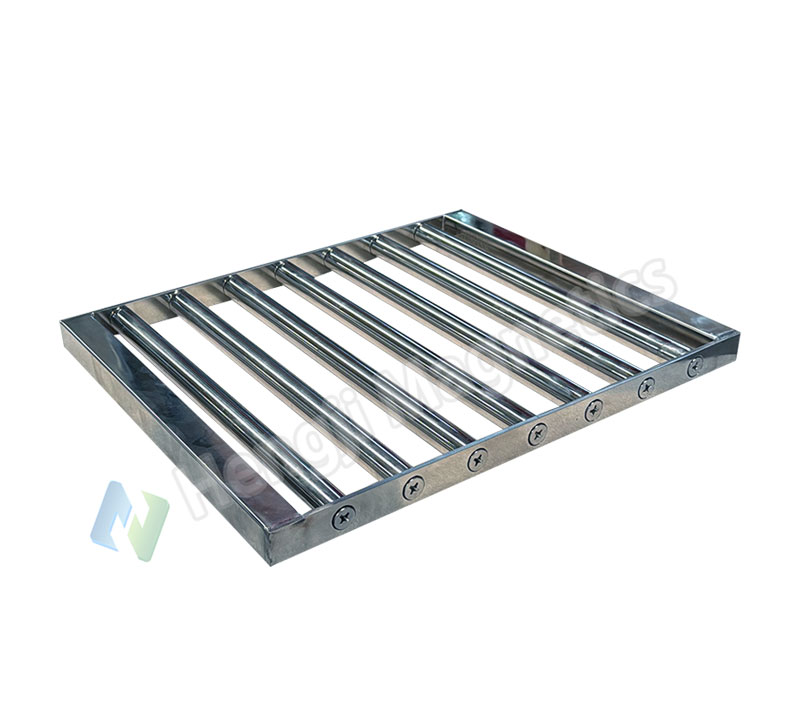

Exceptional Magnetic Performance

Utilizing high-grade NdFeB rare-earth magnets, this advanced liquid magnetic separator delivers powerful magnetic force with customizable flux density up to 12,000 Gauss. The comprehensive grid-style magnetic array ensures uniform field distribution, while the multi-layer rod design creates a gradient separation effect, making this liquid trap highly effective for comprehensive contamination removal.

Precision Engineering & Construction

Constructed from SUS304/316L stainless steel, this durable trap magnet offers excellent corrosion resistance with multiple connection options. The modular magnetic rod assembly enables easy maintenance, while the specialized sealing system maintains integrity under 0.6MPa pressure, ensuring reliable performance of this liquid magnetic separator in demanding applications.

Reliable Operational Characteristics

Operating automatically without external power, this efficient liquid trap handles temperatures from -20℃ to 80℃ (150℃ for high-temperature models) and viscosities from 0.1 to 10,000cP. The unique magnetic circuit protection in this trap magnet prevents short-circuiting, ensuring consistent performance across diverse processing conditions.

Safety & Environmental Protection

Featuring explosion-proof construction and completely enclosed design, this liquid magnetic separator prevents cross-contamination while operating silently without electromagnetic radiation. The recyclable materials in this liquid trap support sustainability initiatives, making it an environmentally responsible choice for hazardous environments.

CYG Liquid Trap Magnet Separator Working Principle

The CYG liquid magnetic separator operates through an integrated system of permanent magnetic attraction and optimized fluid dynamics, providing efficient ferrous contamination removal in liquid and slurry processing applications.

Magnetic Separation Process

As materials flow through the pipeline, powerful neodymium magnets generate a high-gradient magnetic field perpendicular to the flow direction. This advanced liquid trap system deflects ferrous particles toward the magnetic rods where they become securely captured, while non-magnetic materials continue unaffected through this efficient trap magnet configuration.

Multi-Stage Filtration

The multi-layer magnetic rod design creates a comprehensive liquid trap system that captures larger particles in initial stages while removing finer contaminants subsequently. This progressive approach ensures thorough purification throughout the liquid magnetic separator, maintaining consistent product quality across varying contamination levels.

Self-Cleaning Mechanism

For automated models, the magnetic assembly features specialized movement that transports captured metals to a discharge area. Through magnetic circuit disengagement in this advanced trap magnet, contaminants lose magnetic attraction and fall away by gravity, enabling the liquid magnetic separator to maintain continuous operation without production interruption.

CYG Liquid Trap Magnet Separator Product Parameters

Standard diameter (mm): 50, 80, 100, 120, 150, 200, 250, 300, 350, 400, 450, 500. It can be customized according to customer’s on-site requirements.

CYG Liquid Trap Magnet Separator Applications

Industry Applications

The CYG liquid magnetic separator ensures purity in food and beverage processing for juices, dairy, and edible oils. This efficient liquid trap serves chemical industries by purifying paints, resins, and adhesives, while pharmaceutical manufacturers utilize this trap magnet for iron removal under GMP standards. The equipment also processes ceramic slurries and supports environmental protection through metal recovery from wastewater.

Operational Adaptability

This versatile liquid trap handles material viscosities from 0.1 to 10,000cP with solid content up to 70%. The robust trap magnet operates from -20℃ to 80℃ (150℃ for high-temperature models) at pressures to 0.6MPa, functioning effectively at altitudes ≤3000 meters and humidity ≤90%, making this liquid magnetic separator suitable for diverse environmental conditions.

System Integration

Compatible with various pump types, this liquid magnetic separator supports parallel installation for high-flow applications. The liquid trap integrates with PLC control systems for automated operation, while the trap magnet design enables online cleaning functionality, ensuring uninterrupted maintenance and continuous processing efficiency.

CYG Liquid Trap Magnet Separator Services

Pre-Sales Technical Support

We provide complimentary sample testing and customized solution development for the liquid magnetic separator. Our services include 3D installation planning and technical documentation to ensure your liquid trap system meets specific operational requirements.

Professional Installation Guidance

Detailed installation manuals and on-site supervision ensure proper setup of your trap magnet. We provide precision pipeline alignment and comprehensive post-installation testing to guarantee optimal performance of the liquid magnetic separator.

Operation & Maintenance Training

Comprehensive training covers equipment principles and operation procedures for the liquid trap. We provide detailed maintenance manuals and 24/7 technical support for your trap magnet, ensuring efficient operation and troubleshooting capabilities.

After-Sales Service System

Our 12-month warranty includes lifelong maintenance support for the liquid magnetic separator. Strategic spare parts inventory and regular performance evaluations maintain your liquid trap efficiency, with emergency response within 48 hours.

Upgrade & Modification Services

We offer performance enhancements and functionality expansions for your trap magnet. Equipment relocation and technical improvements keep your liquid magnetic separator updated with evolving process requirements.

Categories

Categories