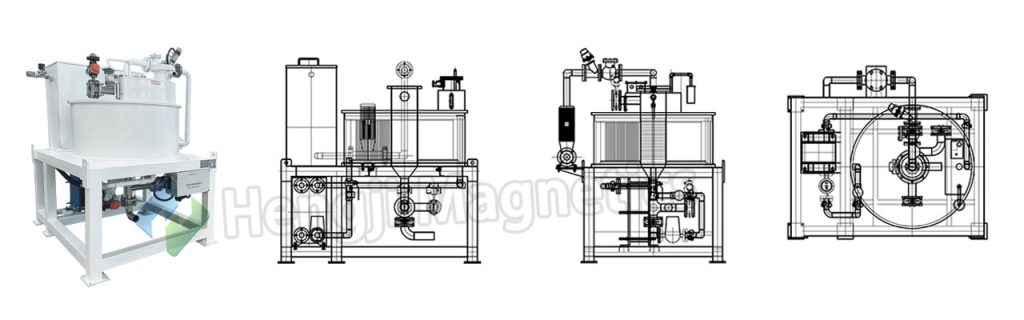

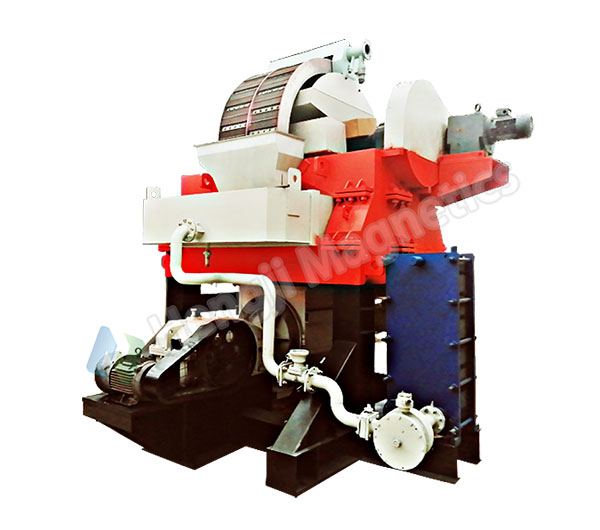

HJLH vertical ring high gradient magnetic separator

● High-Intensity Magnetic Field

Powerful NdFeB magnets deliver superior capturing force.

● Efficient Separation

Effectively captures fine, weakly magnetic materials.

● Optimized Magnetic Circuit

Computer-designed pole arrangement maximizes adsorption area.

● Stable Performance

Sealed magnetic system ensures minimal strength decay over 10 years.

● Fully Automated

Variable frequency drive enables continuous self-cleaning operation.

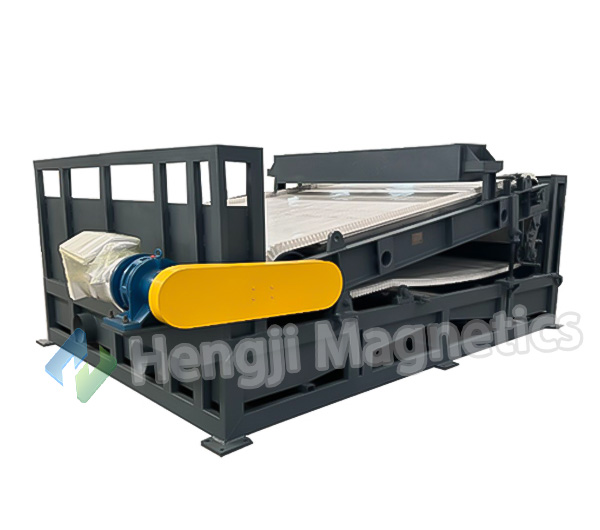

● Wide Applications

Ideal for sub-2mm weakly magnetic minerals and non-metallic ore purification.

● Compact & Durable

Low energy consumption and minimal maintenance ensure long service life.

Categories

Categories