DLS Conveyor Belt Tunnel Metal Detectors Product Overview

The DLS series is a high-precision conveyor belt metal detector for bulk material systems.

This tunnel metal detector uses advanced digital signal processing. It accurately identifies various metals, including iron, copper, and aluminum.

The system outputs alarm or interlock signals to protect downstream equipment. This conveyor belt metal detector prevents damage to crushers and grinders.

This tunnel metal detector is essential for mining, power, and chemical industries. It serves as a critical safety solution for modern production lines.

With its robust design, this conveyor belt metal detector enhances safety and efficiency. It is a reliable choice for diverse industrial applications.

DLS Conveyor Belt Tunnel Metal Detectors Key Features

High Sensitivity Detection

-

Utilizes multi-frequency digital signal processing

-

Detects metal objects as small as Φ20mm iron balls

-

Identifies Φ25mm non-ferrous metals

-

Features adjustable sensitivity levels

-

This conveyor belt metal detector ensures precise operation

Strong Anti-Interference Capability

-

Equipped with automatic material compensation

-

Effectively suppresses “material effect”

-

Handles minerals and coal applications

-

Significantly reduces false alarms

-

This tunnel metal detector ensures reliable bulk material handling

Intelligent Recognition

-

Built-in microprocessor system

-

Distinguishes magnetic and non-magnetic metals

-

Automatically adjusts detection parameters

-

Adapts to material characteristics

-

This conveyor belt metal detector offers smart operation

Stability and Reliability

-

IP54 protection rating

-

Operational range: -20°C to 50°C

-

Includes self-diagnostic functions

-

Ensures reliable performance

-

This tunnel metal detector supports proactive maintenance

Multiple Output Options

-

Provides relay contacts (NO/NC)

-

4-20mA analog signals available

-

RS485 communication interfaces

-

Flexible integration with control systems

-

This conveyor belt metal detector offers versatile connectivity

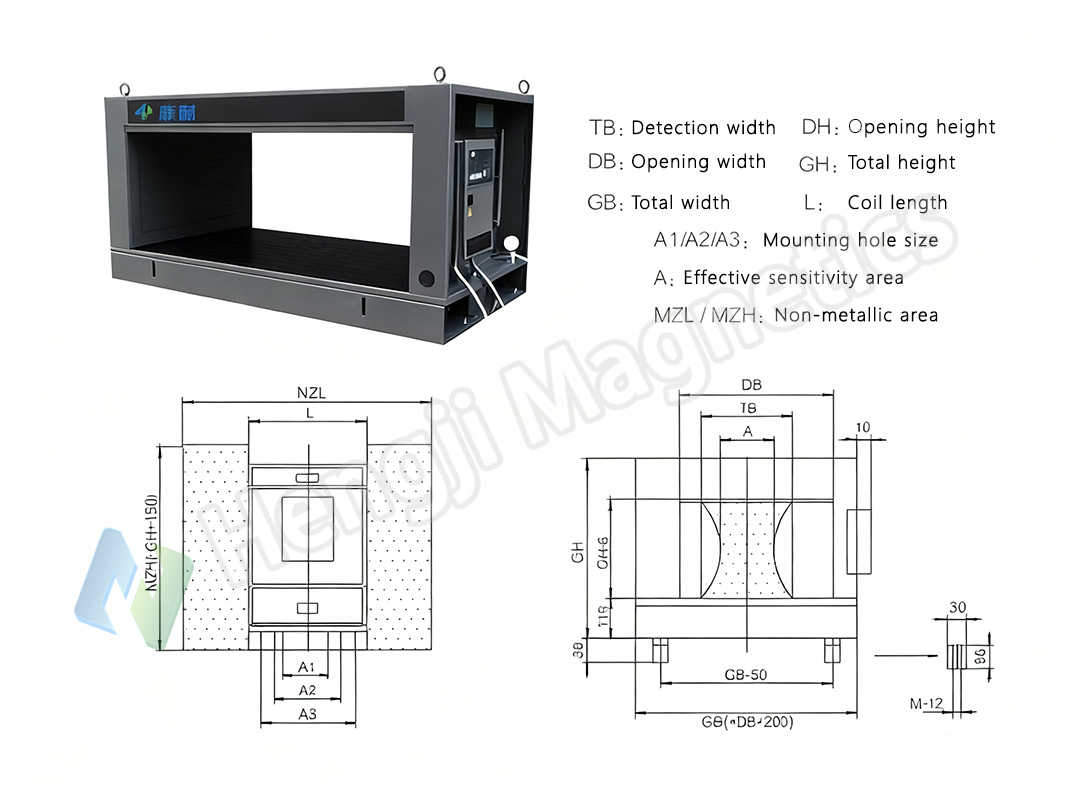

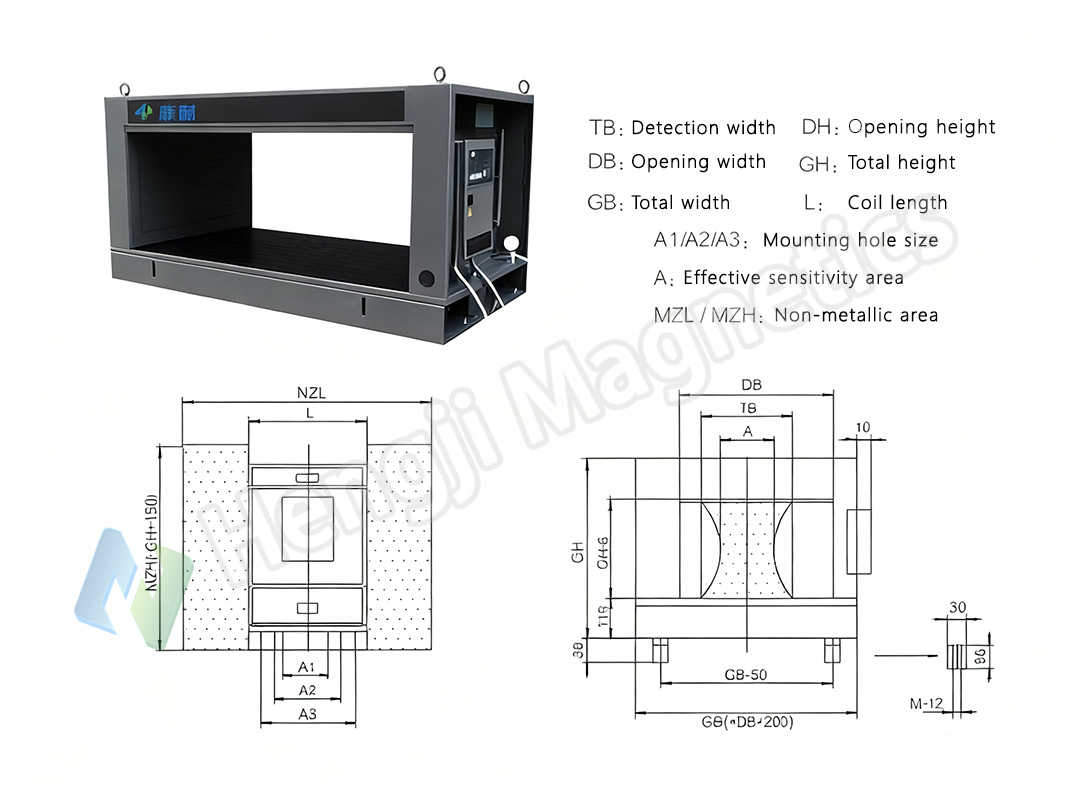

Easy Installation

-

Tunnel-style design

-

No conveyor belt cutting required

-

Supports horizontal mounting

-

Accommodates vertical configurations

-

This tunnel metal detector simplifies installation process

DLS Conveyor Belt Tunnel Metal Detectors Working Principle

Working Principle Overview

-

DLS conveyor belt metal detector uses electromagnetic induction

-

System consists of two main components

-

Includes sensor and controller units

-

The tunnel metal detector generates high-frequency electromagnetic field

Detection Process

-

Sensor creates detection zone

-

Metal objects passing through cause disturbances

-

The conveyor belt metal detector detects signal alterations

-

This tunnel metal detector monitors field changes continuously

Signal Processing

-

Controller amplifies and filters signals

-

Uses specialized digital algorithms

-

The conveyor belt metal detector processes signals accurately

-

Distinguishes metal signatures from material noise

-

This tunnel metal detector ensures reliable detection

Alarm & Control System

-

Activates audible and visual alarms

-

Outputs control signals automatically

-

The conveyor belt metal detector can stop conveyor

-

This tunnel metal detector enables material diversion

Metal Classification

-

Utilizes phase discrimination technology

-

Identifies different metal types accurately

-

Ferrous metals cause phase lag

-

Non-ferrous metals produce phase lead

-

The conveyor belt metal detector enables precise classification

-

This tunnel metal detector provides detailed metal analysis

DLS Conveyor Belt Tunnel Metal Detectors Product Parameters

DLS Conveyor Belt Tunnel Metal Detectors Applications

Mining Industry Applications

-

Ideal for iron and copper ore processing lines

-

This tunnel metal detector prevents crusher damage

-

Removes hazardous metals from coal systems

-

The conveyor belt metal detector handles detonators and tools

Power Generation Applications

-

Protects coal mills in power plants

-

Installed on fuel conveyor belts

-

This tunnel metal detector serves biomass plants

-

The conveyor belt metal detector ensures fuel safety

Building Materials Applications

-

Used in cement production lines

-

Detects metal in limestone conveyors

-

This tunnel metal detector inspects clinker

-

The conveyor belt metal detector processes aggregates

Metallurgy & Chemical Applications

-

Essential for steel plant pre-processing

-

This tunnel metal detector ensures material purity

-

Inspects plastic pellets and fertilizers

-

The conveyor belt metal detector maintains quality

Other Industry Applications

-

Supports metal recovery in waste treatment

-

Ensures metal-free food processing

-

This tunnel metal detector handles grain operations

-

The conveyor belt metal detector offers versatile solutions

DLS Conveyor Belt Tunnel Metal Detectors Purchase Service

Technical Support Services

-

On-site installation guidance provided

-

Professional commissioning services available

-

Free operator training programs

-

Covers conveyor belt metal detector principles

-

Includes daily maintenance procedures

-

Troubleshooting guidance for tunnel metal detector

Customized Solutions

-

Detection parameters optimized for material properties

-

Considers material size, moisture, conductivity

-

Custom conveyor belt metal detector versions available

-

Explosion-proof models offered

-

High-temperature resistant tunnel metal detector

-

Extra-wide belt configurations

System Integration

-

Integrates with magnetic separators and belt scales

-

Enables centralized control systems

-

The conveyor belt metal detector connects seamlessly

-

Communication interface development services

-

DCS/PLC system integration for tunnel metal detector

After-Sales Service

-

18-month warranty on all units

-

Lifelong maintenance support

-

48-hour emergency response guaranteed

-

Quick-replacement spare parts service

-

Comprehensive conveyor belt metal detector support

-

Reliable tunnel metal detector maintenance

Product Advantages

-

DLS Series recognized for high reliability

-

Intelligent operation capabilities

-

Flexible configuration options

-

Preferred conveyor belt metal detector across industries

-

The tunnel metal detector ensures optimal performance

Selection Guidance

-

Careful selection based on material properties

-

Consider conveyor specifications

-

Account for process requirements

-

The conveyor belt metal detector requires proper configuration

-

This tunnel metal detector delivers best results when correctly specified

Categories

Categories