Smart Material Compensation:Auto-compensates for "material effect" from highly magnetic ores using multi-frequency tech.

Broad-Spectrum Metal Detection:Detects ferrous & non-ferrous metals (steel, stainless, Cu, Al) with high sensitivity (down to φ20mm).

No-Cut Installation:Window-type sensor installs without cutting the conveyor belt.

High Stability:Industrial circuits resist EMI and vibration for reliable operation.

Rugged Design:IP54 stainless steel housing; universal sensor base per GB/TD-75.

Large Tramp Metal Protection:Positioned post-magnet to intercept damaging large metal pieces before crushers.

Seamless Integration:DCS interface enables remote control and status monitoring.

The GJT Series, developed and manufactured by our company, is an advanced online detection solution specifically designed for belt conveyor systems handling bulk materials, whether magnetic or non-magnetic. This intelligent industrial metal detector addresses a critical gap in material purification by identifying and eliminating large or non-ferrous metal contaminants—such as stainless steel, manganese steel, copper, and aluminum—that traditional magnetic separators cannot remove.

Positioned as an essential safety device, its primary role is to protect valuable downstream processing equipment, including cone crushers and jaw crushers, from catastrophic damage caused by tramp metal. By ensuring stable and uninterrupted production, the GJT series represents a pivotal advancement in domestic metal detection technology, offering reliable secondary security for modern industrial operations.

Intelligent Detection Technology

This conveyor metal detector employs sophisticated digital phase-shift, multi-channel, and multi-frequency technology. It automatically analyzes the grade and composition of different ores and performs real-time “material effect” compensation. This intelligent adaptation ensures high sensitivity and consistent performance across a wide range of material types without manual retuning.

Exceptional Anti-Interference Capability

Engineered for stability, the system incorporates multiple built-in anti-interference measures and utilizes dedicated chip-based digital circuits. It effectively prevents false triggering caused by external electromagnetic fields (e.g., from welders or motors), belt vibration, and other common industrial disturbances, guaranteeing reliable operation in complex plant environments.

High Precision and Sensitivity

The device offers high and adjustable detection sensitivity, capable of identifying ferrous and non-ferrous metal objects as small as φ20–φ25mm. This precision allows for the accurate recognition and subsequent removal of various harmful metallic contaminants from the material stream, safeguarding product purity and equipment integrity.

Robust and Durable Construction

Designed for longevity, the sensor features a convenient “Window-Type” design that allows for installation without cutting the conveyor belt. The numerical control box is built with a stainless steel, powder-coated housing rated IP54 for outdoor use, providing excellent protection against water, dust, and corrosion.

Seamless Automation Integration

Facilitating modern plant control, this industrial metal detector is equipped with a DCS (Distributed Control System) interface. It enables remote start/stop control and can transmit vital device status signals—such as “Ready,” “Running,” and “Fault”—directly to a central control room for integrated process management.

-

Signal Generation: The control box converts 220V AC power to DC and uses a digital circuit to supply a high-frequency current to the sensor. This current generates a stable, high-frequency electromagnetic field within the sensor’s detection aperture.

-

Metal Identification: As material on the conveyor belt passes through the sensor, any metal object (magnetic or non-magnetic) will disturb this electromagnetic field. This disturbance causes a change in the inductance of the detection coils, producing a faint electrical signal.

-

Signal Processing: The sensor transmits this signal to the industrial-grade digital circuit within the control box. A microprocessor then digitizes, amplifies, and analyzes the signal. Once confirmed as a harmful metal contaminant, a control command is generated.

-

Output and Control: The control box outputs a “switch control signal” lasting approximately one second, activating an internal relay. This signal is available via one set of normally open and one set of normally closed contacts (2A contact capacity). It is typically used to trigger a conveyor stop or activate a diversion mechanism, allowing for the timely manual or automatic removal of the metal contaminant.

|

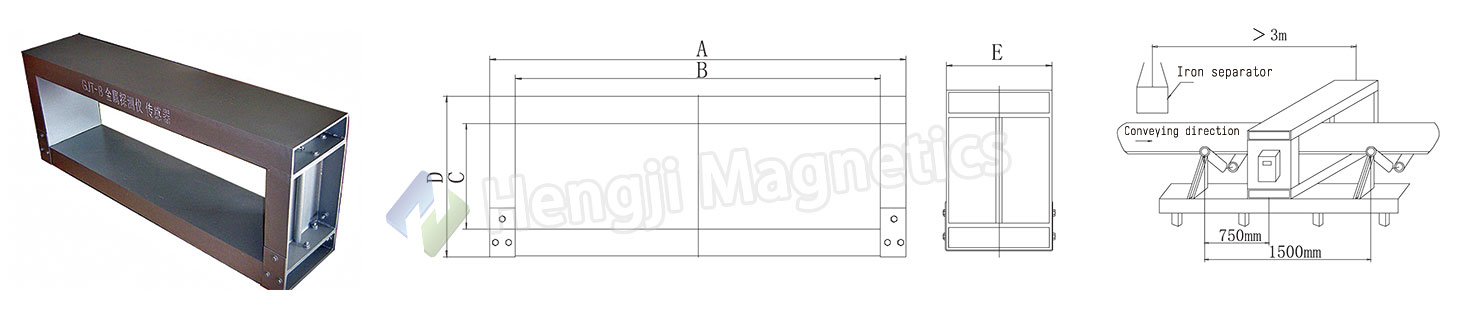

Model |

Adaptable Belt Width (mm) |

Power ≤ (W) |

Adaptable Belt Speed (m/s) |

Input Voltage ~V |

Sensitivity ≥ (mm) |

A |

B |

C |

D |

E |

|

GJT-5B |

500 |

40 |

0.8-2.5 |

220±10% 50Hz |

20 |

850 |

690 |

250 |

410 |

250 |

|

GJT-6B |

650 |

40 |

20 |

1040 |

840 |

250 |

410 |

280 |

||

|

GJT-8B |

800 |

50 |

30 |

1300 |

1100 |

300 |

460 |

280 |

||

|

GJT-10B |

1000 |

50 |

35 |

1350 |

1150 |

350 |

510 |

280 |

||

|

GJT-12B |

1200 |

50 |

40 |

1605 |

1470 |

400 |

580 |

300 |

||

|

GJT-14B |

1400 |

60 |

45 |

1830 |

1680 |

450 |

630 |

300 |

||

|

GJT-16B |

1600 |

60 |

50 |

2050 |

1890 |

500 |

680 |

300 |

||

|

GJT-18B |

1800 |

65 |

55 |

2280 |

2120 |

550 |

730 |

300 |

||

|

GJT-20B |

2000 |

70 |

60 |

2500 |

2340 |

600 |

780 |

300 |

Primary Application Scenario

The GJT conveyor metal detector is ideally installed on a belt conveyor downstream of a magnetic separator but immediately before critical crushers. Acting as a vital secondary security measure, it accurately intercepts metallic “tramp” that evades or is non-responsive to magnetic separation.

Key Protected Equipment

Its core function is to prevent large metal pieces from damaging expensive core processing machinery, such as cone crushers and jaw crushers. This proactive protection helps avoid severe incidents like machine jams, broken gears, and extensive downtime, ensuring operational continuity and significant cost savings.

Applicable Industries

-

Mining: Ferrous metal mines (e.g., iron ore) and non-ferrous metal mines.

-

Mineral Processing & Smelting: Ironworks and sintering plants.

-

Building Materials & Raw Materials: Quarries and cement plants.

-

General Industry: Suitable for any bulk material handling system that processes materials containing either magnetic or non-magnetic metals.

Professional Installation Guidance

We provide detailed installation manuals outlining critical considerations. Key instructions include positioning the sensor midway between two idlers, locating it away from strong electromagnetic interference sources, and using independent support brackets to minimize vibration.

Commissioning & Operational Support

Complete guidance is offered for pre-startup checks, recommended power-on procedures, and sensitivity adjustment to ensure optimal setup for your specific application.

Comprehensive Troubleshooting

The product manual includes clear guidelines for diagnosing and resolving common issues. The device itself is equipped with a self-diagnostic circuit to aid in quick fault identification.

Customization & Upgrade Options

The GJT series offers strong versatility. We provide model selection and custom upgrade services tailored to user-specific requirements, including conveyor belt width, belt speed, and specific detection sensitivity needs.

Categories

Categories