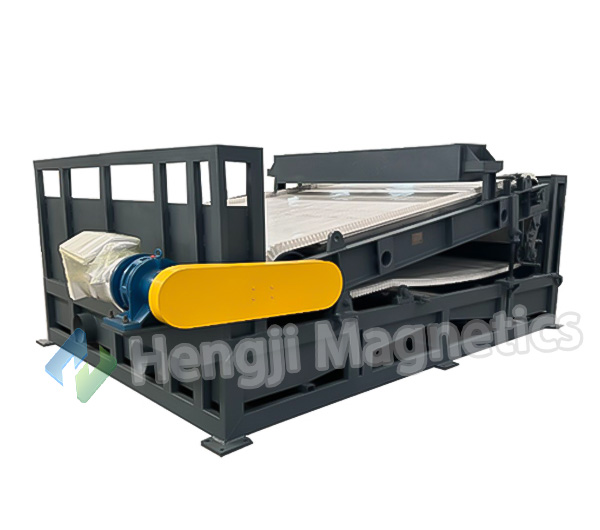

GTC Belt Wet High Intensity Magnetic Separator Product Overview

The GTC series is a breakthrough in magnetic separation. This advanced wet high intensity magnetic separator processes weakly magnetic minerals.

Featuring an innovative plate-type design, this belt magnetic separator integrates principles from physics and fluid dynamics. It achieves unprecedented separation efficiency.

Its unique magnetic pole arrangement generates up to 18,000 Gauss. This wet high intensity magnetic separator sets new benchmarks in mineral processing.

This robust belt magnetic separator handles materials below 5mm particle size. It effectively solves challenges like clogging and excessive carryover.

The GTC series offers revolutionary advancements for non-metallic mineral purification. This wet high intensity magnetic separator combines high efficiency with operational economy.

GTC Belt Wet High Intensity Magnetic Separator Key Features

Exceptional Magnetic System Performance

-

Uses high-purity NdFeB magnets

-

Delivers magnetic force up to 18,000 Gauss

-

Features innovative opposing pole arrangement

-

Fully sealed system design

-

Ensures minimal magnetic decay

-

This wet high intensity magnetic separator sets global standards

-

The belt magnetic separator provides high-gradient separation

Intelligent Control System

-

Features stepless speed regulation motors

-

Enables fully automated operation

-

Includes motorized stirring mechanism

-

Ensures uniform material distribution

-

Frequency conversion allows parameter adjustments

-

This wet high intensity magnetic separator adapts to materials

-

The belt magnetic separator offers flexibility

Optimized Structural Design

-

Constructed with stainless steel components

-

Prevents secondary contamination

-

Offers flexible configuration options

-

Includes specialized wear treatments

-

Extends equipment service life

-

Reverse counter-current design enables automatic discharge

-

This wet high intensity magnetic separator is efficient

-

The belt magnetic separator simplifies operations

Reliable Operational Performance

-

Handles 1-25 tons per hour

-

Processes weakly magnetic minerals below 5mm

-

Adapts to various slurry concentrations

-

Requires minimal maintenance

-

Offers trouble-free operation

-

This wet high intensity magnetic separator is robust

-

The belt magnetic separator serves demanding applications

GTC Belt Wet High Intensity Magnetic Separator Working Principle

Operating Principle

-

GTC plate-type wet high intensity magnetic separator uses reverse counter-current principle

-

Integrates multiple systems for efficient separation

-

This advanced belt magnetic separator combines several components

-

Includes frame support and magnetic separation plates

-

Features feeding mechanisms and water supply

-

Contains discharge systems in coordinated unit

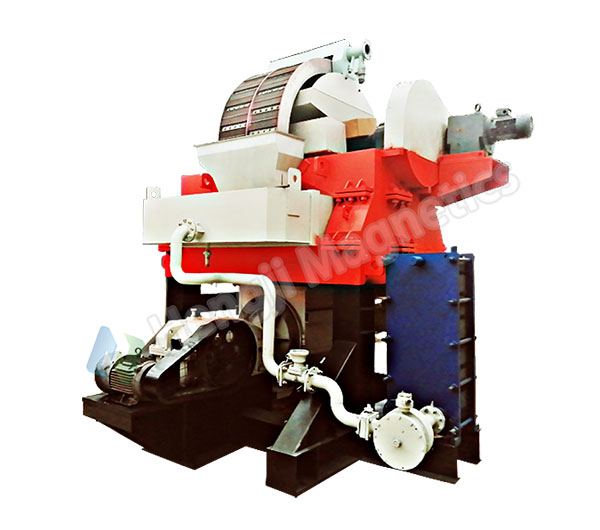

Magnetic Separation Process

-

Material flow opposes discharge system movement

-

This wet high intensity magnetic separator creates counter-current flow

-

Non-magnetic materials flow toward discharge outlet

-

Achieves complete cleaning through discharge flushing

-

Magnetic substances undergo extensive exposure

-

Long-distance, multi-stage adsorption in powerful fields

-

This belt magnetic separator captures materials effectively

-

Reverse-operating system transports materials to outlet

Material Control System

-

Precisely controls material layer thickness (1-5mm)

-

Thickness adjusted based on material concentration

-

Considers particle size variations

-

This wet high intensity magnetic separator maintains optimal conditions

-

Integrated adjustment system ensures separation efficiency

-

This belt magnetic separator provides precise control

-

Maintains consistent performance across feed variations

GTC Belt Wet High Intensity Magnetic Separator Product Parameters

GTC Belt Wet High Intensity Magnetic Separator Applications

GTC Belt Wet High Intensity Magnetic Separator Services

Professional Technical Support

-

Complimentary consultation and model selection.

-

Our experts conduct material analysis and site assessments.

-

We deliver customized solutions for the wet high intensity magnetic separator.

-

Services include layout design and foundation drawings.

-

All plans are tailored for your belt magnetic separator system.

Installation & Commissioning

-

Professional engineers supervise the entire process.

-

Precision adjustments are performed on-site.

-

We provide parameter optimization guidance.

-

Ensures your belt magnetic separator operates at peak efficiency.

-

This wet high intensity magnetic separator is optimized from initial startup.

After-Sales Support System

-

12-month warranty with lifelong maintenance included.

-

We maintain detailed customer records with regular follow-ups.

-

24-hour technical support is available.

-

Comprehensive spare parts supply is ensured.

-

Keeps your belt magnetic separator running smoothly.

-

Supports the long-term operation of your wet high intensity magnetic separator.

Operation Training

-

Detailed operation manuals are provided.

-

On-site training covers all operational procedures.

-

We offer maintenance planning guidance.

-

Online tutorials are available for your system.

-

Ensures proficient operation of your wet high intensity magnetic separator.

-

Builds expertise for your belt magnetic separator team.

Upgrade & Modification Services

-

Performance enhancements are available.

-

Functional expansions adapt to your process changes.

-

We offer professional relocation services.

-

Regular optimization recommendations are provided.

-

Keeps your wet high intensity magnetic separator up-to-date.

-

Ensures your belt magnetic separator meets evolving needs.

Categories

Categories