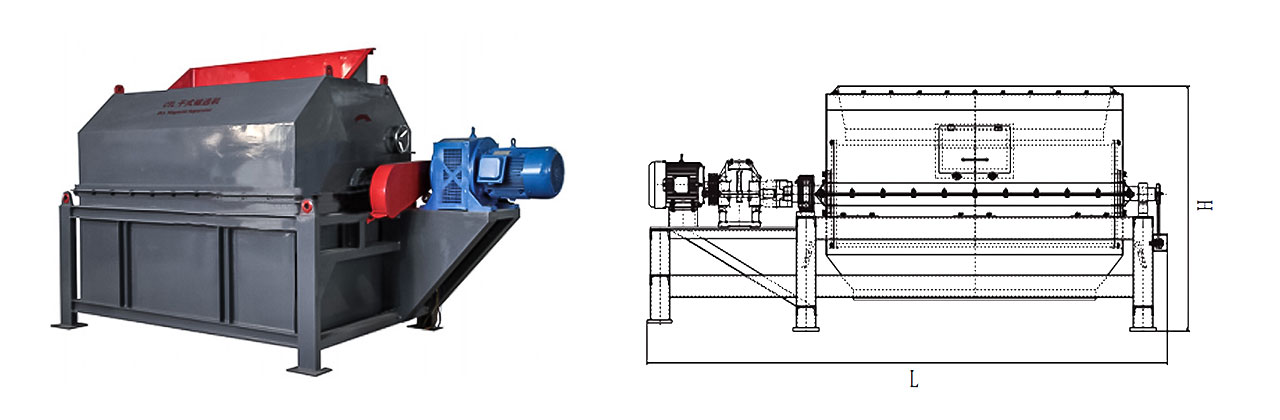

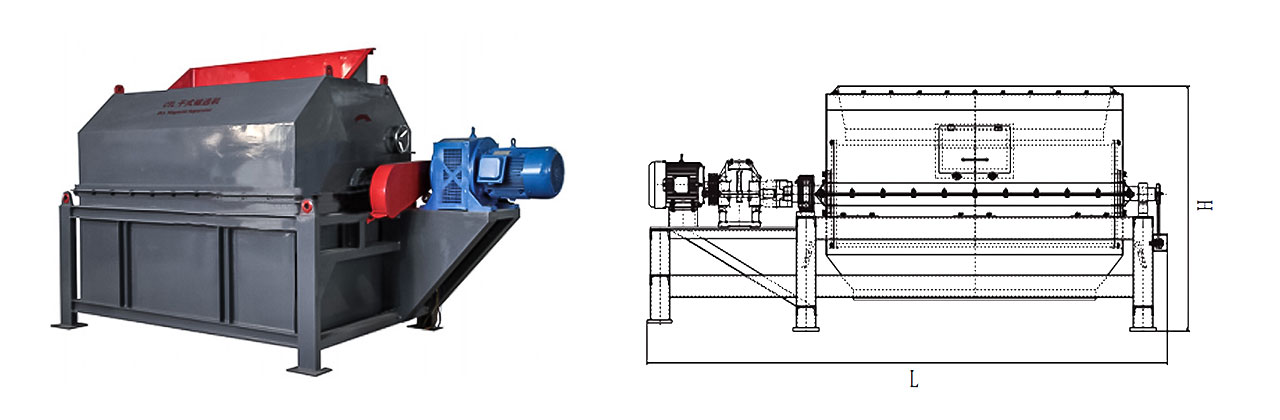

HCG Dry Drum High Intensity Magnetic Separator Product Overview

The HCG Series is an advanced dry high intensity magnetic separator for removing ferrous contaminants. It is a high-performance dry drum magnetic separator for dry powder materials.

Its unique magnetic system design is effective for magnetic iron ore pre-concentration. This dry drum magnetic separator improves grinding efficiency and reduces costs.

As an innovative dry high intensity magnetic separator, it achieves up to 1.5 times the processing capacity of conventional equipment. Speed is adjusted via a frequency converter.

This dry drum magnetic separator handles materials from 0-12mm particle size. It provides reliable solutions for various industrial applications.

ISO9001 certified, this dry high intensity magnetic separator delivers consistent performance. It maintains minimal operational costs and enhanced production efficiency.

HCG Dry Drum High Intensity Magnetic Separator Key Features

Exceptional Mineral Processing Performance

-

This advanced dry drum magnetic separator features a unique semi-circular magnetic system.

-

The system creates an extensive magnetic field area with strong capture capability.

-

The optimized magnetic circuit design ensures significant separation efficiency.

-

This dry high intensity magnetic separator effectively controls tailings loss.

-

The design simultaneously improves the final concentrate grade.

High Processing Capacity

-

The drum speed is controlled via a frequency converter.

-

This allows the dry drum magnetic separator to achieve up to 1.5 times the capacity of conventional equipment.

-

It features continuous, automatic iron removal capability.

-

This capability of the dry high intensity magnetic separator significantly enhances overall production efficiency.

-

The system also contributes to reducing long-term operational costs.

Wide Application Adaptability

-

The equipment features a unique material distribution structure.

-

This structure allows for flexible adjustment of both concentrate and tailings grades.

-

This adjustability is a key feature of the dry drum magnetic separator.

-

This versatile dry high intensity magnetic separator effectively processes 0-12mm powder ores.

-

It is suitable for handling various other dry materials across multiple industries.

Reliable Mechanical Structure

-

The drum is constructed from durable stainless steel.

-

It maintains a minimal distance (≤4mm) between the magnetic system and the drum surface.

-

This design in the dry drum magnetic separator maximizes magnetic efficiency and capture rate.

-

The overall structure is robust and built with heavy-duty components.

-

This ensures the dry high intensity magnetic separator operates stably in the most demanding environments.

-

It is engineered for reliable, continuous industrial use.

HCG Dry Drum High Intensity Magnetic Separator Working Principle

Working Principle Overview

-

The HCG dry high intensity magnetic separator operates through permanent magnetic attraction principles.

-

It features a semi-circular magnetic system housed within its rotating drum.

-

This system generates an extensive and powerful magnetic field.

-

The field is designed for efficient material separation.

Magnetic Separation Process

-

As materials pass through the magnetic field zone of this dry drum magnetic separator, magnetic minerals are captured.

-

They are held by strong magnetic forces and adhere to the rotating drum surface.

-

The drum’s continuous rotation transports these captured materials to designated non-magnetic zones.

-

In these zones, gravitational force discharges the materials through the concentrate outlet.

-

This completes the efficient separation cycle in this advanced dry high intensity magnetic separator.

Material Separation Mechanism

-

Non-magnetic materials and ores with low iron content pass through the magnetic field unaffected.

-

They are not influenced by magnetic forces within the dry drum magnetic separator.

-

These materials exit the system through the tailings outlet via simple gravity flow.

-

The entire separation process of this dry high intensity magnetic separator is highly efficient.

-

It ensures minimal valuable material loss and achieves maximum product purity.

Operational Advantages

-

This efficient separation process makes the HCG dry drum magnetic separator particularly effective.

-

It is specifically designed for dry processing applications.

-

The equipment’s design prioritizes water conservation, making it an environmentally friendly choice.

-

It also emphasizes overall processing economy and low operational costs.

-

These features make this dry high intensity magnetic separator ideal for modern operations.

-

It is perfect for sites where environmental considerations and cost efficiency are paramount concerns.

HCG Dry Drum High Intensity Magnetic Separator Product Parameters

HCG Dry Drum High Intensity Magnetic Separator Applications

Primary Application Fields

-

The HCG dry drum magnetic separator excels in magnetic iron ore pre-concentration.

-

It is highly effective for dry powder ore processing.

-

This versatile dry high intensity magnetic separator performs critical non-metallic mineral iron removal.

-

It enhances the quality of various building materials.

-

The system provides industrial powder purification across multiple manufacturing sectors.

Process Application Range

-

This dry drum magnetic separator enables continuous, automatic iron removal from dry powder materials.

-

It is capable of handling 0-12mm powder ores for pre-concentration purposes.

-

The efficient dry high intensity magnetic separator improves grinding grades within mineral processing circuits.

-

It integrates seamlessly into fully automated production lines.

-

This integration helps optimize overall plant operations and consistency.

Industry Application Value

-

The dry drum magnetic separator significantly reduces overall mineral processing costs.

-

This advanced dry high intensity magnetic separator improves the economic returns of processing operations.

-

It simplifies complex production processes, making them more efficient.

-

The technology consistently enhances final product quality and purity.

-

It supports sustainable industrial operations through its water-free dry separation technology.

-

The system delivers substantial operational and economic value across a wide range of industrial applications.

HCG Dry Drum High Intensity Magnetic Separator Services

Professional Installation Guidance

-

We provide detailed installation manuals and dedicated technical support.

-

This support is for the proper setup of your dry drum magnetic separator.

-

Our process ensures correct equipment leveling and reliable grounding.

-

Our experts assist with critical verification steps, including drum rotation checks.

-

We deliver comprehensive setup services for your complete dry high intensity magnetic separator system.

Operation Training

-

We deliver complete, hands-on training covering all startup sequences.

-

Training includes making all necessary operational adjustments for the dry drum magnetic separator.

-

We provide expert guidance on using the frequency converter for speed control.

-

Training also covers magnetic field optimization techniques for your dry high intensity magnetic separator.

-

The program incorporates essential safety protocols and procedures for continuous, safe operation.

Maintenance Support

-

Our comprehensive maintenance programs include detailed wear parts identification.

-

We provide clear schedules for mandatory inspections of the dry drum magnetic separator.

-

We help establish and maintain detailed maintenance records for your equipment.

-

Our service includes providing proven troubleshooting guidance.

-

This support is dedicated to maintaining your dry high intensity magnetic separator system in peak condition.

After-Sales Service

-

Our extensive national service network provides prompt technical support.

-

This support is readily available for your dry drum magnetic separator.

-

We guarantee the supply of 100% genuine spare parts for all components.

-

We conduct regular service follow-ups with our customers.

-

This commitment ensures the optimal, long-term performance of your dry high intensity magnetic separator throughout its entire operational lifecycle.

Categories

Categories