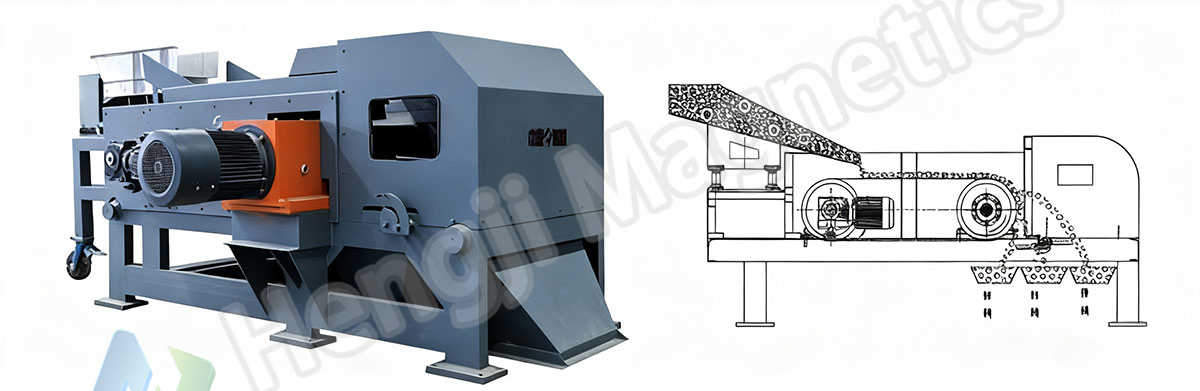

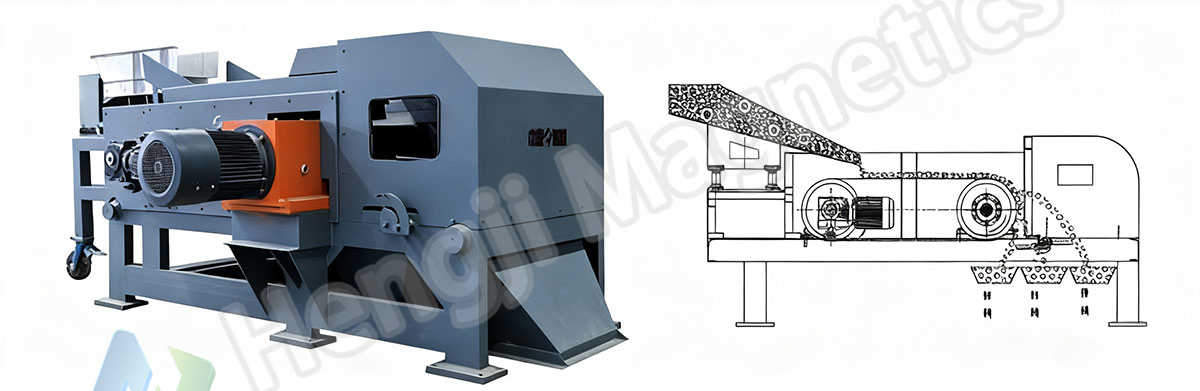

HECS Eddy Current Non-ferrous Metal Magnetic Separator Product Overview

The HECS Eddy Current Separator recovers non-ferrous metals like copper and aluminum. It is a high-efficiency eddy current metal separator for industrial and municipal waste.

Utilizing advanced technology, this eddy current magnetic separator generates a high-frequency alternating magnetic field. It effectively separates non-ferrous metals from non-metallic materials.

This eddy current non ferrous metal separator is produced by a National High-Tech Enterprise. It holds ISO9001 and CE certifications.

It is widely used in electronic waste processing and end-of-life vehicle recycling. This eddy current metal separator is essential for non-ferrous metal processing industries.

The equipment provides an intelligent, energy-saving solution. This eddy current magnetic separator improves resource recovery and supports sustainable development goals.

HECS Eddy Current Non-ferrous Metal Magnetic Separator Key Features

High Sorting Efficiency

-

Processes up to 12 m³/h of material

-

Sorting efficiency exceeds 95%

-

Ensures optimal recovery rates

-

This eddy current metal separator excels in recycling operations

Precision Sorting Capability

-

Separates materials based on conductivity

-

Uses density ratios for classification

-

Enables precise non-ferrous metal recovery

-

This eddy current magnetic separator handles complex waste streams

Adjustable Operating Parameters

-

Features variable frequency drive technology

-

Drum speed adjustment: 50 to 2800 rpm

-

Accommodates different material characteristics

-

This eddy current non ferrous metal separator offers flexibility

Robust Construction Design

-

Permanent magnetic drum with stainless steel protection

-

Wear-resistant conveyor belt included

-

Modular design simplifies installation

-

This eddy current metal separator ensures durability

-

Easy maintenance design

Intelligent Control System

-

Equipped with frequency converter adjustment

-

Provides simple and intuitive operation

-

Maintains low energy consumption

-

This eddy current magnetic separator offers smart control

Environmental Compatibility

-

Operates without secondary pollution

-

Supports eco-friendly processing

-

Handles electronic waste materials

-

Processes industrial residues

-

This eddy current non ferrous metal separator is environmentally safe

HECS Eddy Current Non-ferrous Metal Magnetic Separator Working Principle

Operating Principle

-

Based on alternating magnetic fields generating alternating electric fields

-

This eddy current magnetic separator uses high-frequency magnetic fields

-

The eddy current metal separator induces currents in conductive materials

Magnetic Field Generation

-

Sorting magnetic drum produces alternating magnetic field

-

High-frequency field created during operation

-

This eddy current non ferrous metal separator targets passing metals

-

The eddy current metal separator activates conductive materials

Eddy Current Induction

-

Alternating fields induce eddy currents

-

Currents flow within non-ferrous metals

-

This eddy current magnetic separator generates internal currents

-

The eddy current non ferrous metal separator activates metal particles

Separation Mechanism

-

Eddy currents create secondary magnetic field

-

Secondary field opposes original magnetic field

-

Magnetic repulsion propels metals forward

-

This eddy current metal separator separates materials effectively

-

The eddy current magnetic separator uses repulsion force

Material Processing

-

Separates conductive metals from non-metallics

-

Propels non-ferrous metals along conveyor

-

This eddy current non ferrous metal separator ensures clean separation

-

The eddy current metal separator handles mixed streams

Separation Efficiency Factors

-

Efficiency depends on conductivity-to-density ratio

-

Higher ratio materials separate more easily

-

This eddy current magnetic separator excels with aluminum and copper

-

The eddy current non ferrous metal separator recovers valuable metals

Target Applications

-

Particularly effective for aluminum recovery

-

Excellent for copper separation

-

This eddy current metal separator processes mixed waste streams

-

The eddy current magnetic separator handles recycling operations

HECS Eddy Current Non-ferrous Metal Magnetic Separator Applications

Waste Recycling Applications

-

Recovers non-ferrous metals from e-waste

-

Handles refrigerators and air conditioners

-

This eddy current metal separator processes automotive recycling

-

The eddy current magnetic separator separates aluminum and copper components

-

Handles shredded end-of-life vehicles

Industrial Applications

-

Recovers valuable metals from boiler bottom ash

-

Separates aluminum cans from mixed waste

-

This eddy current non ferrous metal separator serves industrial waste processing

-

The eddy current metal separator handles construction material recycling

-

Separates non-ferrous metals from glass and plastic waste

Production Purification

-

Ensures product quality in plastic recycling

-

Removes non-ferrous metal impurities

-

This eddy current magnetic separator processes production lines

-

The eddy current non ferrous metal separator serves wood processing

-

Separates metal contaminants from wood waste

Environmental Protection

-

Enables efficient recovery in municipal solid waste treatment

-

Supports circular economy initiatives

-

This eddy current metal separator promotes sustainable resource management

-

The eddy current magnetic separator handles various recycling applications

HECS Eddy Current Non-ferrous Metal Magnetic Separator Product Parameters

HECS Eddy Current Non-ferrous Metal Magnetic Separator Services and Support

Customization Services

-

Customized dimensions available

-

Tailored sorting parameters

-

Magnetic drum diameters: 320mm/400mm

-

Specialized solutions for specific materials

-

This eddy current metal separator offers flexible configurations

-

Custom designs for eddy current magnetic separator

Installation & Commissioning

-

Professional leveling calibration

-

On-site belt tracking adjustment

-

Optimizes splitter plate position

-

Trial operation guidance provided

-

Complete setup for eddy current non ferrous metal separator

-

Technical commissioning for eddy current metal separator

Maintenance Services

-

Regular reducer inspection

-

Bearing lubrication services

-

Monitors conveyor belt wear

-

Replacement services available

-

Comprehensive maintenance guidance

-

Complete care for eddy current magnetic separator

-

Magnetic drum system support for eddy current non ferrous metal separator

Technical Training

-

Equipment operation training

-

Fault diagnosis procedures

-

Safety protocols covered

-

Troubleshooting common issues

-

Professional training for eddy current metal separator

-

Comprehensive education for eddy current magnetic separator

-

Operational guidance for eddy current non ferrous metal separator

After-Sales Support

-

12-month machine warranty

-

24-month core component coverage

-

24-hour technical consultation

-

Rapid maintenance services

-

Lifetime spare parts supply

-

Continuous support for eddy current metal separator

-

Lifecycle support for eddy current magnetic separator

Categories

Categories