Core Structural Innovations

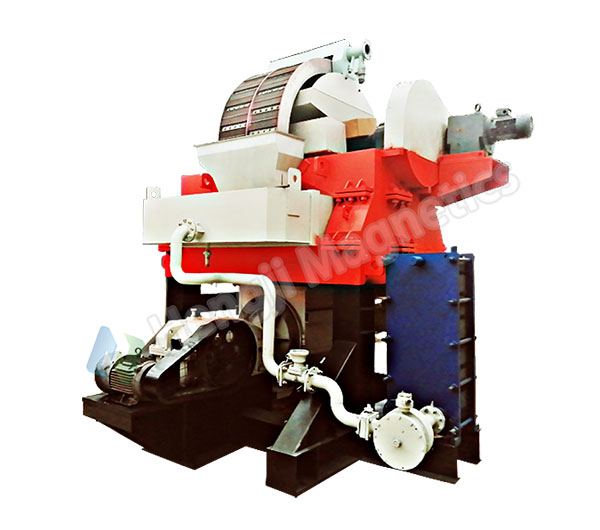

The HJLH Vertical Ring High Gradient Magnetic Separator features:

Vertical Ring Magnetic Assembly

• Rotating stainless steel rod/mesh media for particle capture

• Optimized media configuration preventing buildup

• Vertical orientation maximizing magnetic exposure

Advanced Magnetic Circuit

• Oil-Cooled Excitation System:

Sealed coils maintain 1.5T fields

• Precision magnetic yokes eliminating flux leakage

• Transformer oil immersion + forced air cooling

Intelligent Material Handling

• Variable pulsation mechanism

• Self-regulating feed system

• Corrosion-resistant construction

Efficient Separation Process

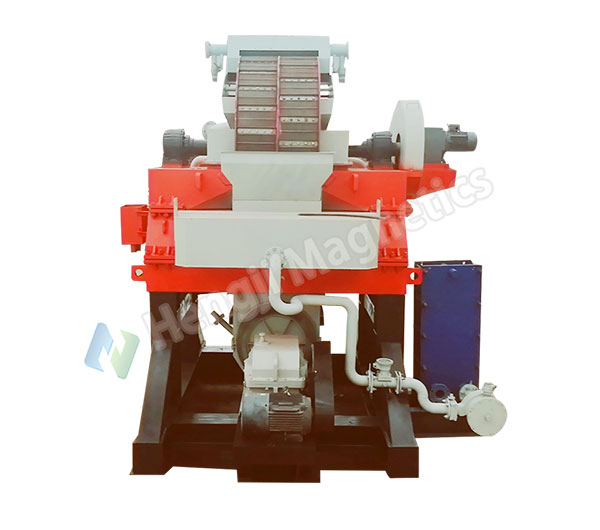

Continuous Four-Stage Operation

- Slurry introduction through precision hopper

- Magnetic Capture Phase:

Vertical ring media adsorbs particles (core function of the HJLH Vertical Ring High Gradient Magnetic Separator)

- Automatic discharge via water jets

- Tailings separation

Process Optimization

• Adjustable pulsation control

• Consistent flow dynamics

Performance Advantages

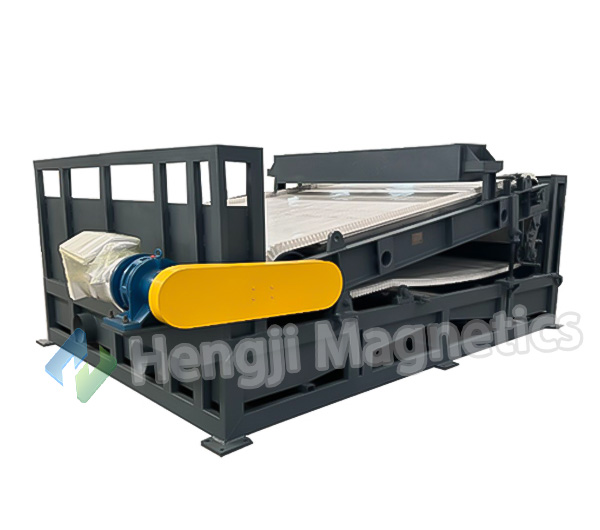

Superior Mineral Recovery

• Fine particle processing (<30μm)

• High-gradient separation efficiency

Operational Reliability

• Patented anti-clogging technology

• Low-maintenance sealed design

Adaptive Processing

• Handles hematite/manganese ores

• Adjustable parameters

Technical Differentiation

Innovative Engineering

• Oil-cooled system outperforms conventional designs

• Modular media options

• Intelligent process control

Durability Advantages

• Extended component lifespan

• Simplified maintenance access

→ *Critical for 24/7 operation of the HJLH Vertical Ring High Gradient Magnetic Separator*

Product Parameters

Industry Applications

The HJLH Vertical Ring High Gradient Magnetic Separator excels in:

• Metallic Mineral Recovery: Hematite, tungsten, rare-earth

• Industrial Purification: Quartz, feldspar, kaolin

• Tailings Reprocessing

• Non-Metallic Upgrading

Categories

Categories