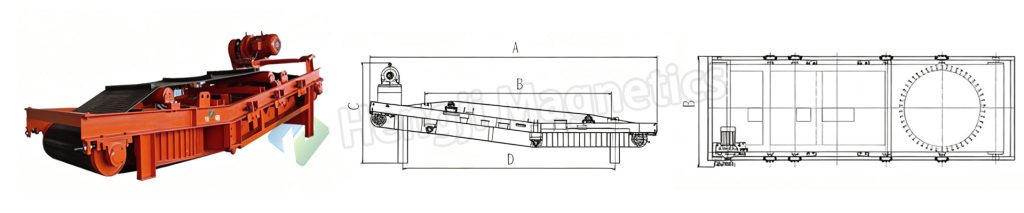

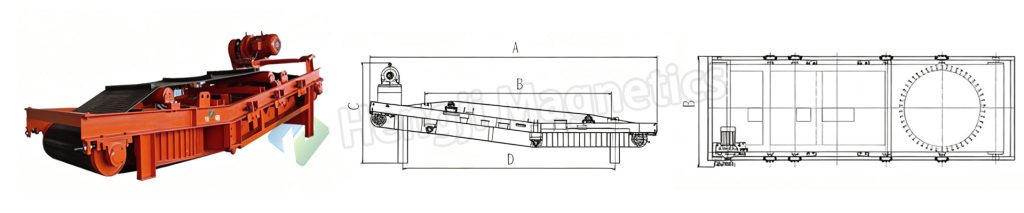

LJK Magnetic Iron Ore Separator For Conveyor Belt Product Overview

The LJK series represents a significant advancement in magnetic separation technology, specifically engineered to address the unique challenges of extracting ferrous contaminants from magnetic ores. This innovative magnetic iron ore separator utilizes specialized magnetic field configurations and high-sensitivity detection systems to effectively remove tramp iron from magnetic materials, overcoming the limitations of conventional separators that often exhibit poor performance and significant ore carryover.

As a specialized magnetic separator for conveyor belt systems handling magnetic materials, the LJK series integrates magnetic assemblies, structural framework, conveyor belt, drive system, and control cabinet. When combined with metal detectors and discharge platforms, it forms a complete iron removal solution specifically designed for magnetic ore processing applications, delivering superior performance where standard separation equipment typically fails.

LJK Magnetic Iron Ore Separator For Conveyor Belt Key Features

Innovative Magnetic System Design

Featuring a unique primary and auxiliary pole configuration, this advanced magnetic iron ore separator effectively extracts large iron plates, steel bars, and other challenging ferrous contaminants. The optimized magnetic circuit and expanded separation zone significantly reduce ore carryover, making this magnetic separator for conveyor belt systems particularly effective where conventional equipment fails.

Intelligent Control System

Equipped with specialized metal detection technology that accurately distinguishes tramp iron from magnetic ores, this magnetic iron ore separator minimizes false signals. The automated control cabinet ensures stable operation through precise programming, while optimized excitation timing prevents valuable ore loss in this sophisticated magnetic separator for conveyor belt applications.

Energy Efficient Operation

The unique magnetic core structure and circuit design substantially reduce power consumption, achieving over 30% energy savings compared to conventional separators. The self-cooling coil system in this magnetic iron ore separator provides excellent insulation with low temperature rise, ensuring efficient heat dissipation for the magnetic separator for conveyor belt.

Robust Structural Design

With fully enclosed construction and concentrated magnetic flux in the lower separation area, this magnetic iron ore separator generates immediate strong magnetic fields. The lightweight yet powerful design of this magnetic separator for conveyor belt delivers high separation efficiency while withstanding demanding operating conditions.

LJK Magnetic Iron Ore Separator For Conveyor Belt Working Principle

The LJK magnetic iron ore separator operates through a sophisticated multi-stage separation process with precise timing control, specifically designed for magnetic separator for conveyor belt applications handling magnetic materials.

Detection and Identification Phase

A specialized metal detector continuously scans conveyed materials, accurately identifying ferrous contaminants while ignoring magnetic ore signals. Upon detection, signals immediately transmit to the automatic control cabinet, initiating the separation sequence in this advanced magnetic iron ore separator.

Adsorption and Separation Phase

Instant strong excitation activates as tramp iron reaches the main magnetic poles, with immediate transition to holding excitation to minimize ore entrapment. The captured materials transport via belt for initial magnetic separation in this efficient magnetic separator for conveyor belt system.

Multi-Stage Separation Process

Bulk magnetic ores return to the conveyor during initial separation, while remaining materials enter specially configured magnetic zones for refined processing. The majority of magnetic materials successfully return to the main conveyor flow through this optimized magnetic iron ore separator design.

Final Separation Stage

Minimal remaining materials and tramp iron move to the non-magnetic discharge platform where complete de-energization enables final separation. Ferrous contaminants divert to collection while valuable ore returns to the processing system, completing the cycle of this precision magnetic separator for conveyor belt.

LJK Magnetic Iron Ore Separator For Conveyor Belt Product Parameters

|

Model

|

Cooling Method

|

Applicable Belt Width (mm)

|

Average Power (kW)

|

Main Magnetic Pole Power (kW)

|

Auxiliary Magnetic Pole Power (kW)

|

Iron Unloading Belt Width (mm)

|

Driving Power (kW)

|

Matching Electrical Control Model

|

Overall Dimensions (mm) – A

|

Overall Dimensions (mm) – B

|

Overall Dimensions (mm) – C

|

Overall Dimensions (mm) – D

|

Overall Dimensions (mm) – E

|

Weight (kg)

|

|

LJK-3506

|

Natural Cooling

|

650

|

≤2.4

|

8.1

|

12.9

|

500

|

3.0

|

GLA-LK-3506

|

2950

|

850

|

1000

|

2100

|

1700

|

1470

|

|

LJK-4008

|

Natural Cooling

|

800

|

≤4

|

18.4

|

18.9

|

650

|

4.0

|

GLA-LK-4008

|

3300

|

1060

|

1180

|

2400

|

1950

|

2200

|

|

LJK-4510

|

Natural Cooling

|

1000

|

≤5.2

|

25.2

|

24.6

|

800

|

5.5

|

GLA-LK-4510

|

3500

|

1263

|

1263

|

2545

|

2100

|

3000

|

|

LJK-5012

|

Natural Cooling

|

1200

|

≤6

|

27.4

|

30.5

|

1000

|

7.5

|

GLA-LK-5012

|

4145

|

1463

|

1460

|

3032

|

2675

|

3800

|

|

LJK-5514

|

Natural Cooling

|

1400

|

≤7

|

28.3

|

32

|

1200

|

11

|

GLA-LK-5514

|

4330

|

1720

|

1560

|

3240

|

2650

|

5300

|

|

LJK-6016

|

Natural Cooling

|

1600

|

≤8.8

|

32

|

36

|

1400

|

15

|

GLA-LK-6016

|

4600

|

1910

|

1620

|

3370

|

2700

|

6100

|

|

LJK-6518

|

Natural Cooling

|

1800

|

≤10.5

|

47

|

40

|

1600

|

15

|

GLA-LK-6518

|

4800

|

2130

|

1800

|

3565

|

3000

|

9000

|

|

LJK-7020

|

Natural Cooling

|

2000

|

≤12.6

|

57

|

44

|

1800

|

18.5

|

GLA-LK-7020

|

5000

|

2420

|

1800

|

3700

|

3200

|

13000

|

|

LJK-7522

|

Natural Cooling

|

2200

|

≤14.1

|

71

|

48

|

2000

|

22

|

GLA-LK-7522

|

5400

|

2620

|

2000

|

4100

|

3500

|

16800

|

LJK Magnetic Iron Ore Separator For Conveyor Belt Application

Magnetic Ore Processing

The magnetic iron ore separator provides essential raw material purification in iron ore beneficiation plants, while ensuring comprehensive conveyor system protection during magnetic ore handling. This specialized magnetic separator for conveyor belt applications effectively safeguards crushers and grinding equipment throughout ore processing operations.

Metallurgical Industry

In steel production facilities, the magnetic iron ore separator enables reliable raw material pre-treatment, while also serving non-ferrous metal smelting operations. This versatile magnetic separator for conveyor belt systems efficiently removes iron contaminants from various metallurgical auxiliary materials.

Building Materials Sector

Cement plants utilize the magnetic iron ore separator for processing magnetic raw materials, while glass manufacturers benefit from its iron purification capabilities. This adaptable magnetic separator for conveyor belt installations also ensures contaminant removal in refractory material production.

Additional Applications

The technology provides crucial conveyor system protection across mining operations and supports industrial waste recovery processes. The magnetic iron ore separator meets specialized material purification requirements, demonstrating the flexibility of this advanced magnetic separator for conveyor belt technology across multiple industrial sectors.

LJK Magnetic Iron Ore Separator For Conveyor Belt Services

System Commissioning

We provide comprehensive commissioning for your magnetic iron ore separator, including complete system debugging and metal detector sensitivity calibration. Our technicians perform precise magnetic pole positioning and field strength optimization to ensure your magnetic separator for conveyor belt operates at peak efficiency from initial startup.

Technical Training

Our training programs cover operational principles and standard procedures for both the magnetic iron ore separator and magnetic separator for conveyor belt systems. We provide detailed troubleshooting guidance and parameter adjustment techniques to maximize equipment performance and longevity.

After-Sales Support

Complete wear parts identification and replacement guidance specific to your magnetic iron ore separator configuration. Our 24/7 technical consultation services and regular performance evaluations ensure your magnetic separator for conveyor belt maintains optimal operation throughout its service life.

Customized Solutions

We develop tailored solutions based on your specific material characteristics and operating conditions. Our engineering team provides equipment modifications and system upgrade recommendations to optimize your magnetic iron ore separator and magnetic separator for conveyor belt for unique application requirements.

Categories

Categories