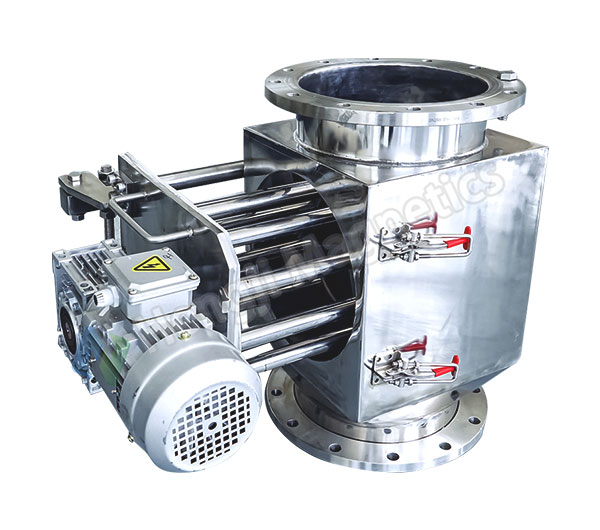

CYG Liquid Trap Magnet Separator

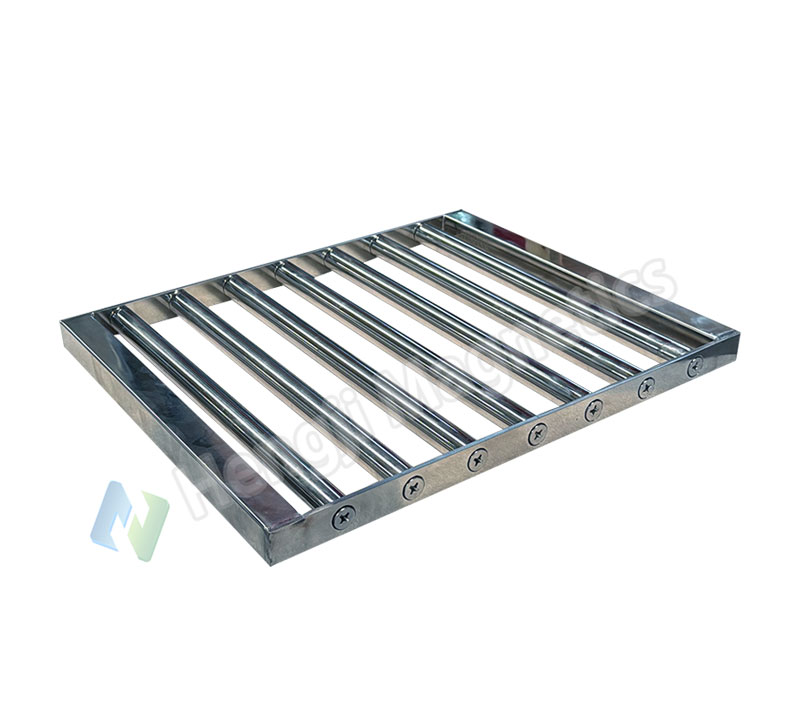

The CYG Liquid Line Magnetic Trap is an innovative solution designed to effectively remove fine ferrous contaminants, including weakly magnetic particles, from liquids, slurries, and pastes. Its advanced high-intensity magnetic technology ensures efficient extraction, making it an ideal choice for maintaining cleanliness and quality in continuous production lines.

Built with sanitary construction, the CYG Liquid Line Magnetic Trap not only protects sensitive processing equipment but also guarantees product purity by removing impurities without interrupting the production flow. Its durable design and reliable performance make it suitable for a wide range of industrial applications.

With its exceptional ability to enhance operational efficiency and ensure the highest standards of product safety, the CYG Liquid Line Magnetic Trap has become a trusted choice for industries prioritizing quality and reliability.

Categories

Categories