Choosing the right magnetic separator is a critical financial decision that impacts your daily operations and long-term profitability. The choice often comes down to a basic but crucial question: manual or automated? Understanding the true return on investment (ROI) between a traditional suspended magnetic separator requiring manual cleaning and a modern, self-cleaning overbelt magnetic separator is key to optimizing your plant’s efficiency and costs.

The Core Difference: Initial Investment vs. Ongoing Cost

The most visible difference is upfront.

-

Manual Suspended Magnetic Separator: This is a powerful magnet in a sealed housing. It effectively captures tramp metal but requires a complete production stop. An operator must then manually clean the collected iron, a process that involves downtime, labor, and safety procedures.

-

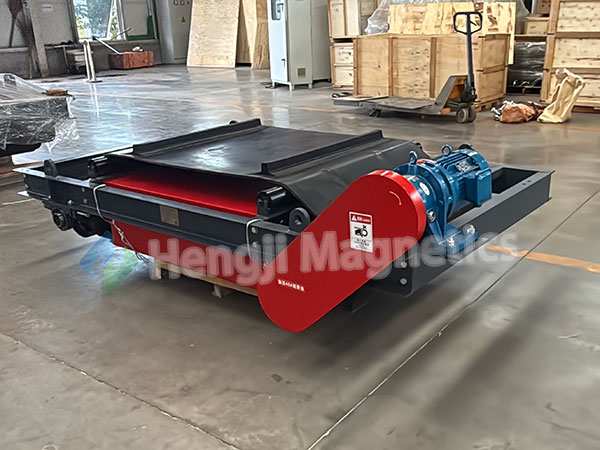

Automated Overbelt Magnetic Separator: This system integrates the magnet with a self-cleaning mechanism—a belt, motor, and scrapers. It continuously discharges captured metal into a collection bin without stopping the process line or requiring manual intervention.

While the automated overbelt magnetic separator carries a higher initial purchase price, this is only one part of the financial equation. The real analysis begins when you calculate the operational costs it eliminates.

The Hidden Costs of Manual Operation

The Hidden Costs of Manual Operation

A manual suspended magnetic separator introduces significant, recurring operational expenses that are often overlooked:

-

Labor Cost: Every cleaning cycle requires paid operator time. In high-contamination environments, this can add up to hundreds of hours per year.

-

Production Downtime Cost: Each time the line stops for cleaning, you lose valuable production output. This lost capacity is a direct hit to your revenue potential.

-

Safety & Risk Cost: Manual cleaning exposes personnel to moving machinery and heavy metal parts, increasing the risk of injury and associated liability.

-

Inconsistency & Inefficiency: Cleaning frequency depends on human schedules, leading to potential overloading of the magnet (reducing efficiency) or unnecessary early stops.

The Automated Advantage: Calculating Continuous Savings

An overbelt magnetic separator systematically converts those variable costs into predictable, automated operation. The savings are direct:

-

Eliminated Manual Labor: The cost of labor for cleaning is reduced to zero. Personnel are redeployed to more valuable tasks.

-

Zero Cleaning Downtime: Production runs continuously. The separator cleans itself on-the-fly, protecting your line’s maximum possible uptime and output.

-

Enhanced Safety: Removing personnel from the cleaning process significantly reduces workplace risk.

-

Consistent Peak Performance: The automated system maintains optimal magnetic strength by continuously discharging captured metal, ensuring protection never dips.

ROI Framework: When Does Automation Pay Off?

ROI Framework: When Does Automation Pay Off?

The Return on Investment for upgrading to an automated overbelt magnetic separator can be calculated by comparing its incremental cost against your annual savings.

Simple Payback Period = (Additional Cost of Automated System) / (Annual Operational Savings)

Annual Savings Typically Include:

-

Labor Savings: (Hourly Rate x Hours Spent Cleaning Annually)

-

Downtime Value Recovery: (Production Value per Hour x Hours of Downtime Avoided)

-

Indirect Savings: Reduced safety incidents, lower management overhead, and prevented downstream equipment damage.

Application Scenarios: Making the Right Choice

-

Choose an Automated Overbelt Magnetic Separator If:

-

Your material has moderate to high ferrous contamination.

-

Your line operates with high value-per-hour or requires maximum uptime.

-

Labor costs are high, or you are optimizing for a leaner, safer workforce.

-

Your process is part of an automated, continuous-flow system.

-

-

A Manual Suspended Magnetic Separator May Suffice If:

-

Ferrous contamination is very low and infrequent (cleaning needed only a few times a year).

-

The initial capital budget is extremely constrained, and planned, scheduled downtime is already accounted for in the process without cost penalty.

-

Conclusion: Investing in Uninterrupted Production

The decision between a manual suspended magnetic separator and an automated overbelt magnetic separator is fundamentally about how you value continuous operation. Automation represents a strategic shift from a variable operational expense (labor + downtime) to a fixed capital investment. For most modern processing facilities, the ROI is clear and compelling. The increased initial investment in an overbelt magnetic separator pays for itself—often within a surprisingly short period—through relentless uptime, eliminated labor costs, and a safer, more efficient plant. In the long run, the most expensive separator is the one that frequently stops your production line.

Categories

Categories