Struggling with sticky, damp, or ultra-fine powders in your production line? Traditional static magnets often fail, leading to clogs, downtime, and inconsistent purity. The solution is innovation in motion. A Rotary Magnetic Separator specifically engineered as a dynamic Grate Magnetic Separator is designed to conquer these exact challenges, ensuring continuous, efficient iron removal where other systems cannot.

Core Innovation: Why Rotation Makes the Difference

-

The Limitation of Static Design: A conventional grate magnetic separator relies on fixed magnetic bars. Adhesive materials like moist powders or sticky granules build up on these surfaces.

-

The Result: This buildup forms an insulating layer that shields incoming material from the magnetic field, drastically reducing capture efficiency.

-

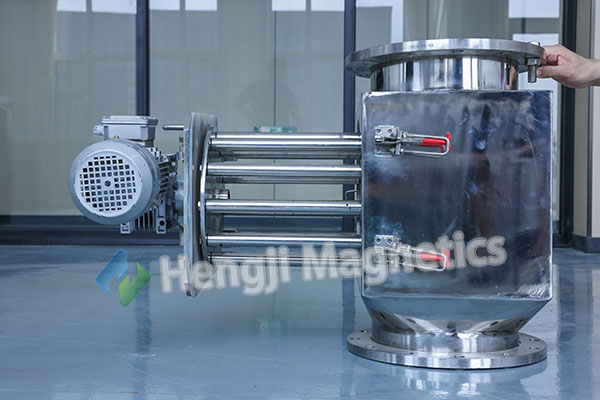

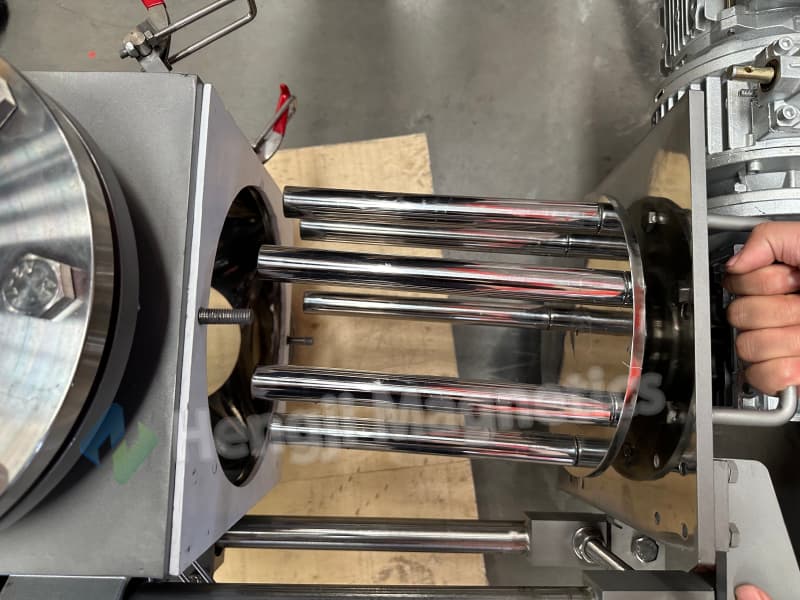

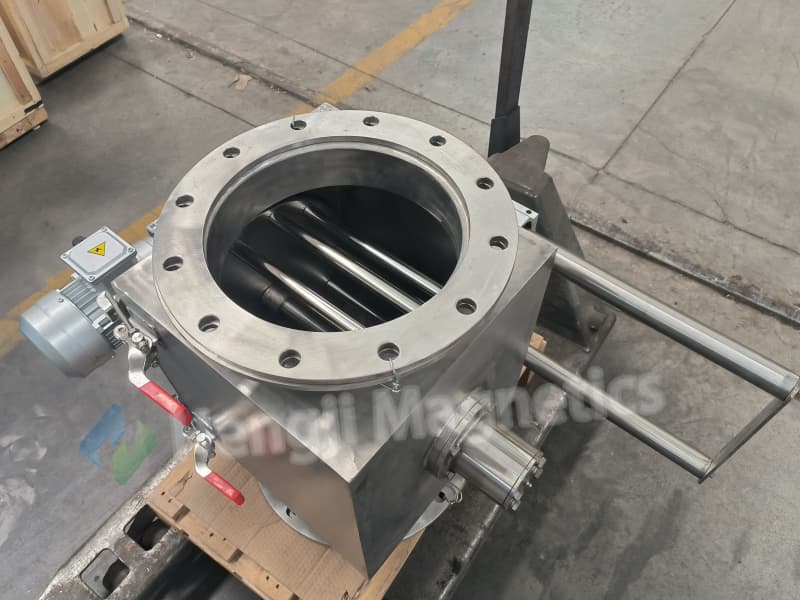

Our Solution – Active Cleaning: The heart of our rotary magnetic separator is its motor-driven magnetic core. The magnetic bars rotate continuously during operation.

-

The Key Benefit: This rotation creates a constant self-cleaning and agitating action. It scrapes away material before it can adhere and ensures the magnetic surface is always exposed for maximum contaminant capture.

Specifically Engineered for Problem Materials

This technology is not a general-purpose tool; it’s a targeted solution for difficult applications.

-

For Sticky & Caking Materials: Prevents the formation of a product layer on the magnet.

-

For Damp or Hygroscopic Products: Stops wet particles from bonding to the magnetic grid.

-

For Ultra-Fine Powders (up to 500 mesh): Prevents fine particles from “blinding” the separator, maintaining full magnetic effectiveness.

Unmatched Versatility in Material Handling

Our rotary magnetic separator is built to handle a remarkably wide spectrum of materials, making it a highly flexible grate magnetic separator solution.

-

Physical Forms: Efficiently processes powders, granules, and flakes.

-

Particle Size Range: Manages everything from large particles (>6mm) down to very fine powders.

-

Material Behavior: Works equally well on free-flowing dry goods and products prone to clumping.

Trusted by High-Standard Industries

When product purity is non-negotiable, industries turn to this reliable technology.

-

Food & Pharmaceutical: Essential for meeting stringent hygiene and safety standards, preventing metallic contamination.

-

Chemicals & Plastics: Protects sensitive processes and ensures the quality of final compounds.

-

Minerals Processing: Critical for purifying materials like quartz sand, feldspar, mica, and fly ash to required specifications.

Built with Performance and Adaptability in Mind

Beyond its rotating core, our separator is designed for power and integration ease.

-

High-Intensity Magnetic Force: Utilizes powerful rare-earth (Neodymium) magnets to ensure strong, deep magnetic fields that capture even weakly magnetic or fine ferrous particles.

-

Flexible Configuration & Installation:

-

Mounting Options: Can be installed in gravity-fed chutes, inline within pipes, or as a standalone unit.

-

Custom Sizing: Available in standard and custom sizes to match your specific pipeline diameter and throughput requirements.

-

Tangible Benefits for Your Operation

Investing in a rotary magnetic separator translates into direct operational improvements over a standard grate magnetic separator.

-

Maximized Uptime: Dramatically reduces clog-related stoppages for cleaner-in-place (CIP) or manual cleaning.

-

Consistent Product Quality: Delivers stable, high-purity output by maintaining peak magnetic efficiency.

-

Reduced Labor & Maintenance: The self-cleaning design lowers the frequency and intensity of required maintenance.

-

Protects Downstream Equipment: By reliably removing tramp metal, it prevents damage to grinders, extruders, and other valuable machinery.

Is a Rotary Grate Magnetic Separator Right for You?

Consider this solution if your process involves:

-

Materials with high moisture or fat content.

-

Powders finer than 100 mesh.

-

Products that are tacky or tend to cake.

-

Applications where frequent magnet cleaning is a production bottleneck.

Conclusion: Stop Compromising, Start Optimizing

Don’t let challenging material characteristics dictate your production limits or product quality. The advanced Rotary Magnetic Separator provides a definitive, reliable answer. It combines the thorough filtration of a Grate Magnetic Separator with an active, self-cleaning mechanism to solve problems that static magnets cannot.

Ready to achieve new levels of efficiency and purity? Contact our technical experts today. We’ll help you determine the perfect rotary grate magnetic separator configuration to optimize your process, protect your product, and boost your bottom line.

Categories

Categories