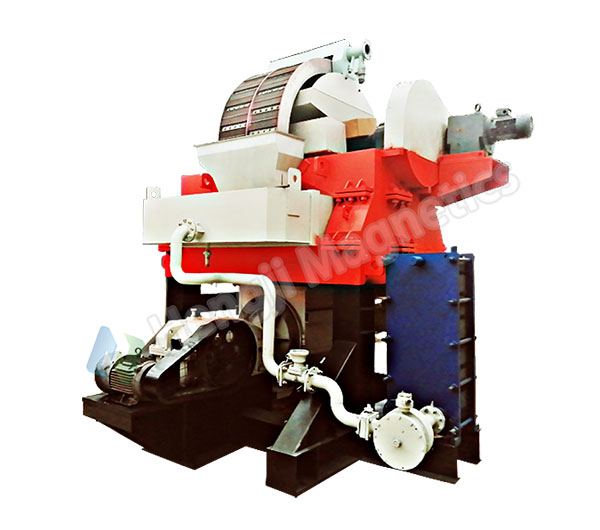

RBCDD Electromagnetic Explosion-proof Magnetic separator For Mining Conveyor

● Explosion-Proof: Exd I Mb mining certification for gas/coal dust environments

● Strong Magnetic Force: 150mT field removes 0.1–50kg iron impurities

● Auto Cleaning: Continuous belt system, >98% efficiency

● Smart Control: Explosion-proof cabinet with overcurrent protection & remote interface

● Energy Efficient: Optimized magnetic circuit, 30% less power consumption

● Durable: Fully sealed, IP65 rating, suits harsh conditions

● Safe Operation: Splash-proof design, low noise (≤75dB)

Customizable: Belt width, explosion-proof grades, and other configurations

Categories

Categories