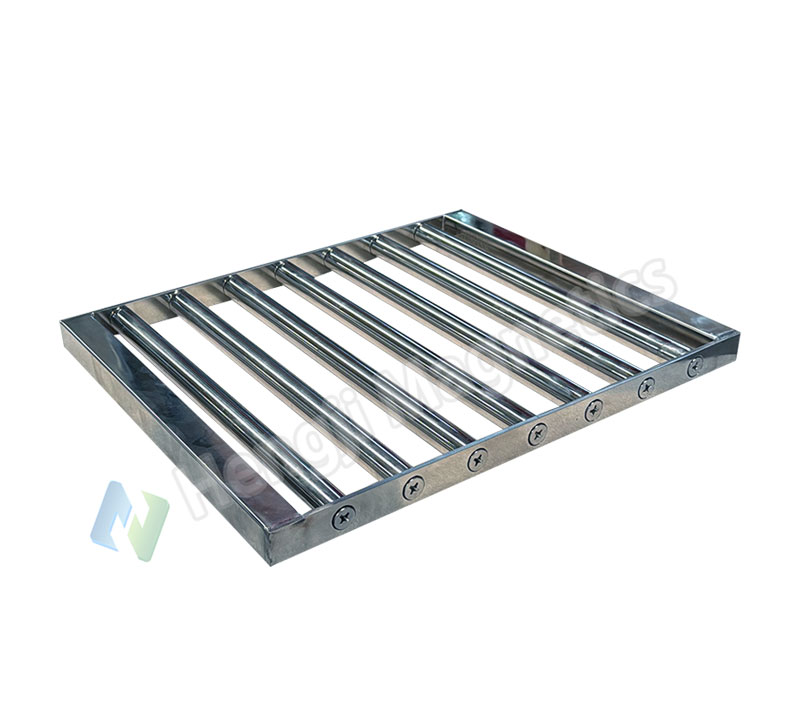

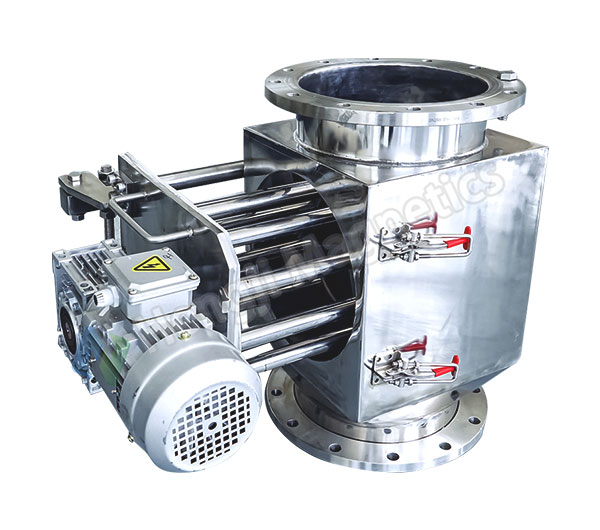

Magnetic rack

The Magnetic Rack delivers reliable ferrous contamination removal in bulk material handling systems. Engineered with high-intensity neodymium magnetic circuits (12,000+ Gauss), this robust solution captures iron particles, stainless steel fragments, and tramp metal down to 30 microns. Its modular design enables seamless installation in hoppers, bins, chutes, and processing equipment without flow disruption.

Versatile industrial protection makes this Magnetic Rack essential for food processing (sugar/flour refinement), pharmaceutical raw material handling, and chemical production where product purity is critical. The 304/316 stainless steel construction features IP69K-rated seals for washdown environments and FDA-compliant surfaces.

Operational advantages include the Magnetic Rack's tool-free cleaning system with quick-release handles, reducing maintenance time by 70%. Custom configurations (1-8 bar layers) ensure 99%+ metal capture while protecting grinders, mixers, and packaging lines downstream.

Categories

Categories