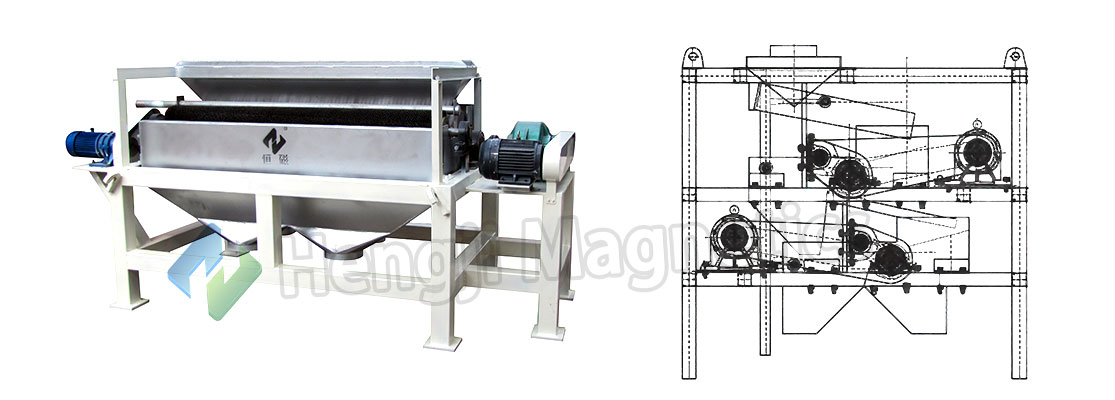

QCG Wet Perm Roll Magnetic Separator Product Overview

The QCG series is an advancement in wet separator technology. It is engineered for processing fine-grained, weakly magnetic ores.

This innovative perm roll magnetic separator features a unique multi-layer magnetic roll configuration. It enables multiple separation stages within a single compact unit.

Its modular design allows flexible combinations of magnetic field intensities. This wet separator provides exceptional adaptability to various processing requirements.

The QCG series employs permanent magnetic circuits for stable, energy-efficient performance. This perm roll magnetic separator supports configurations with up to 10 rolls.

It effectively processes complex ores containing mixtures of magnetic minerals. This advanced wet separator is ideal for operations demanding high-purity concentrates.

QCG Wet Perm Roll Magnetic Separator Key Features

Innovative Multi-Stage Separation Design

-

Features a dual-layer roll structure.

-

Configurable combinations support up to 10 separation stages.

-

Each layer offers independently adjustable parameters.

-

Specialized brush rolls ensure effective cleaning.

-

This advanced perm roll magnetic separator is highly efficient.

-

It is a versatile wet separator system.

High-Efficiency Magnetic System Configuration

-

Utilizes a rare-earth composite magnetic system.

-

Stainless steel reinforcement is included.

-

Delivers deep penetration capability.

-

Completely waterproof design.

-

Secure adhesive fixation is ensured.

-

This perm roll magnetic separator performs reliably.

-

It excels in demanding wet separator applications.

Optimized Structural Design

-

Specially designed semi-counter-flow tank prevents clogging.

-

Rational slurry flow direction improves recovery rates.

-

Cycloidal reducer transmission is employed.

-

Adjustable deflection mechanism is included.

-

This perm roll magnetic separator is versatile.

-

It is a reliable wet separator.

Reliable Operational Performance

-

Handles feed concentrations ≥10%.

-

Feed rates are adjustable.

-

Maintains stable operation.

-

Bearing temperature rise is kept below 60℃.

-

Features leak-free and low-noise operation.

-

This perm roll magnetic separator confirms industrial-grade durability.

-

It is a robust wet separator system.

QCG Wet Perm Roll Magnetic Separator Working Principle

QCG Wet Perm Roll Magnetic Separator Product Parameters

QCG Wet Perm Roll Magnetic Separator Applications

QCG Wet Perm Roll Magnetic Separator Services

Professional Technical Support

-

We provide comprehensive technical consultation and selection guidance.

-

Our experts deliver tailored equipment configuration recommendations based on specific ore characteristics for the perm roll magnetic separator.

-

We conduct detailed site assessments to develop customized solutions.

-

Our services include creating detailed process flow diagrams and layout designs for your complete wet separator system.

Installation & Commissioning

-

Our professional team guides the foundation construction process.

-

We supervise and assist with the complete equipment installation for the perm roll magnetic separator.

-

We conduct thorough system testing, including both no-load and load operations.

-

We provide comprehensive operator training to ensure optimal performance from day one.

-

Our goal is to ensure your wet separator system achieves peak efficiency from initial startup.

After-Sales Support System

-

The perm roll magnetic separator comes with a comprehensive 12-month warranty.

-

We provide lifelong technical support for your equipment.

-

We maintain detailed customer service records with regular operational follow-ups.

-

Our 24-hour technical service is available to address any concerns promptly.

-

This commitment ensures your wet separator operates at peak efficiency throughout its entire service life.

Operation Training

-

Comprehensive training covers the complete equipment structure.

-

We explain the core operational principles of the perm roll magnetic separator.

-

Training includes all standard operating procedures and safety protocols.

-

We provide detailed maintenance guidance for your wet separator system.

-

The program includes practical troubleshooting methods to maximize your team’s operational competency and system uptime.

Spare Parts Supply

-

We maintain a complete, readily available inventory of genuine spare parts.

-

Our system ensures rapid supply of all critical components for the perm roll magnetic separator.

-

Customers receive regular maintenance reminders to support proactive care.

-

We provide detailed parts lists and lifecycle support.

-

This comprehensive approach ensures the long-term reliability and performance of your wet separator investment.

Categories

Categories