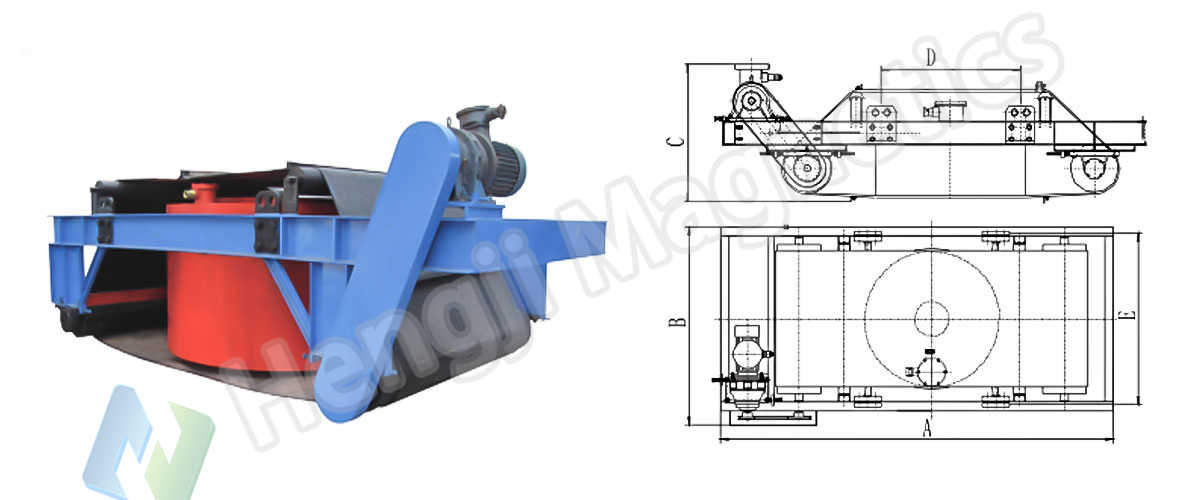

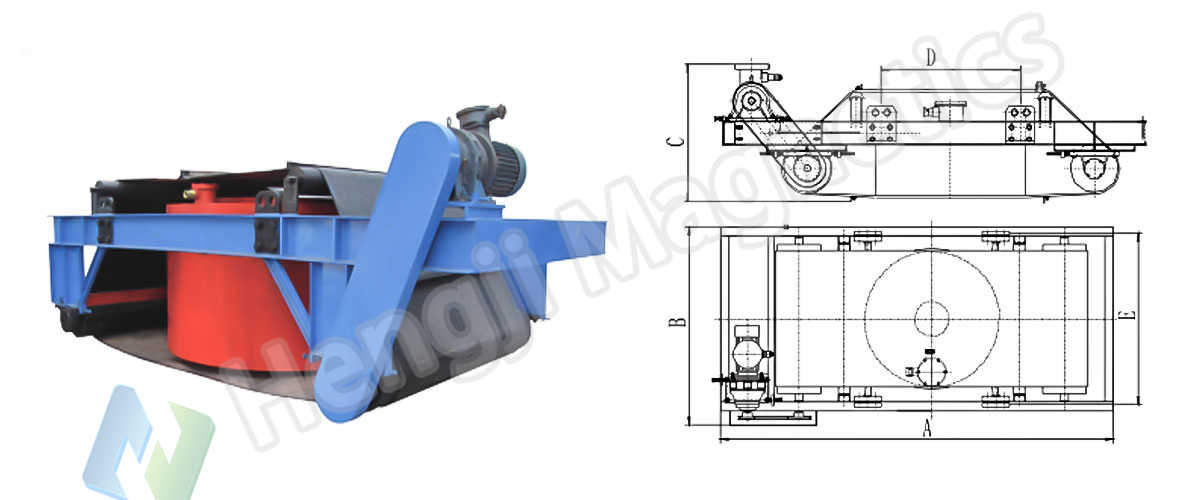

RBCDD Electromagnetic Explosion-proof Magnetic separator For Mining Conveyor Product Overview

The RBCDD series is a flameproof self-cleaning electromagnetic separator. It is designed for safe use in explosive gas or dust environments.

These magnetic separators for mining hold Exd I Mb explosion-proof certification. They comply with GB/T 3836.1-2010 standards.

Featuring a fully enclosed structure, this magnetic separator for conveyor systems integrates with belt conveyors and vibrating feeders.

Its optimized magnetic circuit and automatic cleaning enable efficient ferrous contaminant removal. This magnetic separator for conveyor ensures reliable operation.

Ideal for underground coal mines, these magnetic separators for mining meet stringent safety requirements. They provide reliable purification in hazardous locations.

RBCDD Electromagnetic Explosion-proof Magnetic separator For Mining Conveyor Key Features

Explosion-Proof Certification

-

Mining flameproof design (Exd I Mb)

-

Holds national certification

-

Suitable for methane environments

-

Ideal for coal dust conditions

-

These magnetic separators for mining ensure safety

Powerful Magnetic Strength

-

DT4 electrical pure iron magnetic circuit

-

Delivers up to 150mT (T3 type)

-

Removes ferrous objects (0.1-50kg)

-

This magnetic separator for conveyor handles heavy contaminants

Intelligent Control System

-

Explosion-proof control cabinet

-

Features overcurrent protection

-

Includes temperature monitoring

-

Remote control interfaces

-

These magnetic separators for mining ensure safe operation

Efficient Cleaning Mechanism

-

Explosion-proof motor-driven system

-

Self-cleaning belt with automatic tracking

-

Achieves 98% cleaning efficiency

-

This magnetic separator for conveyor maintains performance

Durable Construction

-

Fully sealed cast steel bearing seats

-

IP65 protection rating

-

Suitable for high-humidity conditions

-

Handles dusty environments

-

These magnetic separators for mining ensure reliability

Energy Efficient Design

-

Optimized coil configuration

-

Reduces power consumption by 30%

-

Noise levels ≤75dB

-

This magnetic separator for conveyor saves energy

Wide Compatibility

-

Handles belt widths 1000-1600mm

-

Supports belt speeds ≤4.5m/s

-

Processes material thickness ≤400mm

-

These magnetic separators for mining offer versatility

RBCDD Electromagnetic Explosion-proof Magnetic separator For Mining Conveyor Working Principle

Operating Principle

-

RBCDD series magnetic separators for mining use electromagnetic induction

-

Explosion-proof control cabinet supplies DC power

-

Excitation coil generates powerful magnetic field

-

Specially designed magnetic poles concentrate field strength

Magnetic Field Generation

-

Creates high-intensity magnetic zone

-

Forms at working gap area

-

This magnetic separator for conveyor establishes strong attraction

-

These magnetic separators for mining generate focused fields

Material Processing

-

Material with ferrous contaminants passes through

-

Iron particles attracted to bottom working surface

-

This magnetic separator for conveyor captures contaminants effectively

-

These magnetic separators for mining handle various materials

Cleaning System

-

Explosion-proof motor drives cleaning belt

-

Continuous operation maintained

-

Captured ferrous materials transported away

-

This magnetic separator for conveyor automates removal

Discharge Mechanism

-

Scraping mechanism removes collected iron

-

Directs materials into designated container

-

Achieves fully automatic operation

-

These magnetic separators for mining require minimal intervention

Cooling Technology

-

Innovative wave-shaped cooling fins

-

Vacuum encapsulation technology

-

Ensures effective heat dissipation

-

This magnetic separator for conveyor maintains temperature

Performance Reliability

-

Consistent performance in extended operation

-

Suitable for demanding environments

-

These magnetic separators for mining ensure reliability

-

This magnetic separator for conveyor handles tough conditions

RBCDD Electromagnetic Explosion-proof Magnetic separator For Mining Conveyor Product Parameters

RBCDD Electromagnetic Explosion-proof Magnetic separator For Mining Conveyor Critical Applications

RBCDD Electromagnetic Explosion-proof Magnetic separator For Mining Conveyor Service and Support

Custom Engineering Solutions

-

Customized dimensions for conveyor widths (1000-1600mm)

-

Specialized protective coatings available

-

Tailored designs for magnetic separators for mining

-

Custom explosion-proof ratings

-

Adapted to material characteristics

-

Ensures safety in hazardous environments

Installation and Commissioning

-

3D installation diagrams provided

-

On-site professional guidance

-

Explosion-proof wiring services

-

Gap adjustment for optimal performance

-

Complete setup for magnetic separator for conveyor

-

Commissioning support included

Maintenance Programs

-

Quarterly explosion-proof inspections

-

Annual coil testing services

-

Maintains magnetic separators for mining reliability

-

Genuine spare parts supply

-

Explosion-proof components available

-

Preventive maintenance programs

Technical Training

-

Specialized operation training

-

Covers magnetic separator for conveyor systems

-

Fault code interpretation

-

Maintenance certification programs

-

Operational safety training

-

Technical skill development

After-Sales Guarantee

-

18-month machine warranty

-

36 months for explosion-proof parts

-

24-hour emergency response

-

Lifetime technical consultation

-

Supports magnetic separators for mining lifecycle

-

Continuous magnetic separator for conveyor support

Categories

Categories