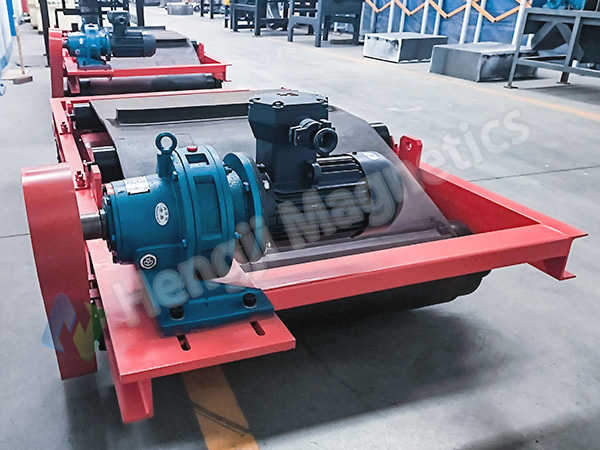

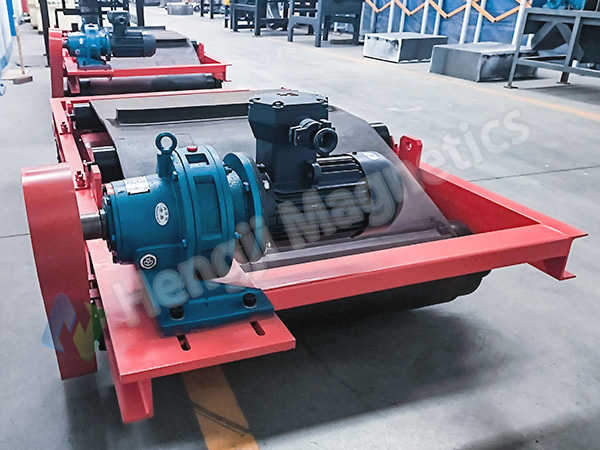

RBCYD Explosion-Proof Permanent Belt Coal Conveyor Magnetic Separator Product Overview

The RCBYD series is a permanent magnet self-cleaning separator. It serves as a highly efficient belt magnetic separator for automatic impurity removal.

Utilizing high-performance NdFeB magnets, this coal conveyor magnetic separator delivers strong magnetic force and deep penetration. It ensures a long service life.

This belt magnetic separator operates continuously without manual cleaning. It consists of a permanent magnetic system and an automatic discharge mechanism.

The coal conveyor magnetic separator is widely used in power generation and mining. It effectively protects downstream equipment from damage.

Ideal for heavy-duty use, this belt magnetic separator provides reliable, maintenance-free operation. It performs reliably in challenging industrial environments.

RBCYD Explosion-Proof Permanent Belt Coal Conveyor Magnetic Separator Key Features

Strong Magnetic Performance

-

Uses high-grade NdFeB magnets

-

Generates intense magnetic fields

-

Extracts ferrous contaminants (0.1kg-35kg)

-

This belt magnetic separator ensures efficient iron removal

-

The coal conveyor magnetic separator handles diverse applications

Automatic Cleaning System

-

Features cycloidal reducer and drive drum

-

Includes discharge belt for continuous operation

-

Enables self-cleaning without production interruption

-

This belt magnetic separator enhances operational efficiency

-

The coal conveyor magnetic separator automates cleaning

Energy Efficiency

-

Permanent magnet system requires no electricity

-

Reduces energy consumption significantly

-

Low operating noise levels

-

This belt magnetic separator is eco-friendly

-

The coal conveyor magnetic separator supports sustainability

Robust Construction

-

Optimized magnetic circuit design

-

Minimal flux decay over time

-

Service life exceeds 10 years

-

This belt magnetic separator withstands harsh conditions

-

The coal conveyor magnetic separator ensures durability

Easy Maintenance Features

-

Online belt tension adjustment

-

Self-lubricating bearings included

-

Minimizes maintenance requirements

-

This belt magnetic separator reduces downtime

-

The coal conveyor magnetic separator lowers operational costs

Wide Applicability

-

Operating range: -20°C to 40°C

-

Handles up to 90% relative humidity

-

Suitable for indoor/outdoor installation

-

IP54 protection rating

-

This belt magnetic separator resists dust and moisture

-

The coal conveyor magnetic separator prevents corrosion

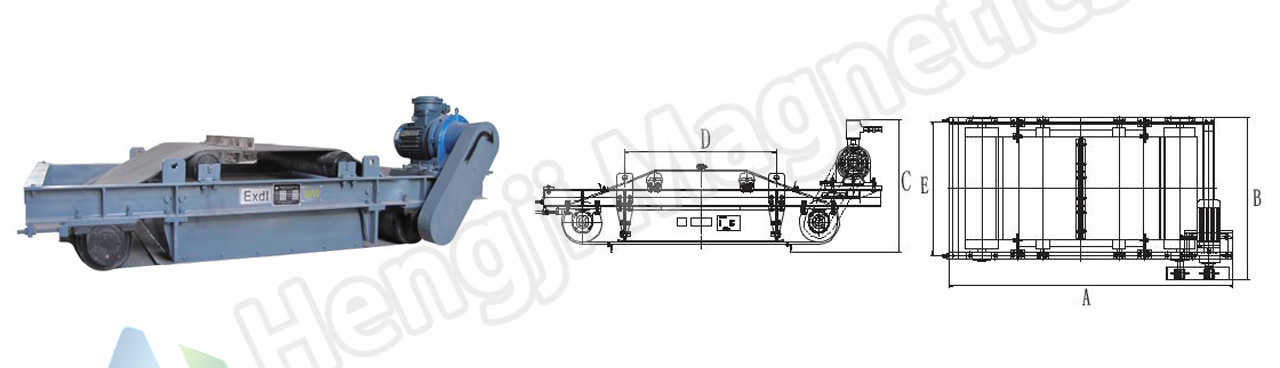

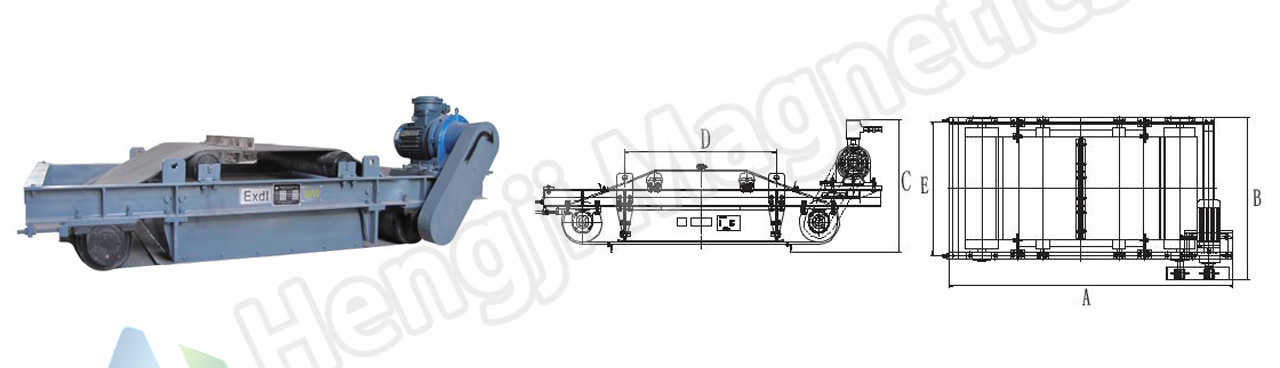

Customization Options

-

Available in various magnetic strengths

-

Multiple dimensions to choose from

-

This belt magnetic separator matches material characteristics

-

The coal conveyor magnetic separator fits conveyor widths

RBCYD Explosion-Proof Permanent Belt Coal Conveyor Magnetic Separator Working Principle

Magnetic Field Generation

-

Generates powerful magnetic field across working surface

-

This belt magnetic separator creates strong attraction force

-

The coal conveyor magnetic separator covers entire processing area

Material Separation Process

-

Bulk materials pass beneath the unit

-

Ferrous particles are attracted and held

-

Self-cleaning belt captures contaminants

-

This belt magnetic separator effectively removes tramp iron

-

The coal conveyor magnetic separator operates during transportation

Cleaning Mechanism

-

Driven by reduction motor

-

Cleaning belt moves continuously

-

Carries ferrous contaminants away

-

This belt magnetic separator maintains material flow purity

-

The coal conveyor magnetic separator ensures continuous operation

Discharge System

-

Discharges metal objects into collection bin

-

Maintains uninterrupted operation

-

This belt magnetic separator automates waste removal

-

The coal conveyor magnetic separator requires minimal intervention

Energy Efficiency

-

External power only for cleaning mechanism

-

Highly energy-efficient design

-

This belt magnetic separator reduces operating costs

-

The coal conveyor magnetic separator optimizes power usage

Operational Flexibility

-

Adjustable belt speed available

-

Accommodates varying feed rates

-

Handles different contamination levels

-

This belt magnetic separator adapts to operational conditions

-

The coal conveyor magnetic separator ensures optimal performance

RBCYD Explosion-Proof Permanent Belt Coal Conveyor Magnetic Separator Product Parameters

RBCYD Explosion-Proof Permanent Belt Coal Conveyor Magnetic Separator Applications

Power Industry Applications

-

Protects coal crushers and pulverizers

-

Installed in coal-fired power plants

-

This coal conveyor magnetic separator ensures continuous operation

-

The belt magnetic separator maintains equipment safety

Mining & Metallurgy Applications

-

Enables pre-processing of iron ore and coal

-

Handles copper ore purification

-

This coal conveyor magnetic separator improves material purity

-

The belt magnetic separator removes ferrous contaminants

Cement & Building Materials

-

Removes tramp iron from limestone

-

Processes sandstone materials

-

This coal conveyor magnetic separator protects grinding equipment

-

The belt magnetic separator maintains product quality

Chemical Industry Applications

-

Purifies raw materials including fertilizer

-

Handles plastic pellet processing

-

This coal conveyor magnetic separator ensures product quality

-

The belt magnetic separator maintains process safety

Coal Processing & Recycling

-

Enhances raw coal cleaning efficiency

-

Removes iron contaminants effectively

-

This coal conveyor magnetic separator facilitates metal recovery

-

The belt magnetic separator protects processing machinery

Port Operations

-

Provides iron removal during loading/unloading

-

Serves ports and terminals operations

-

This coal conveyor magnetic separator ensures material purity

-

The belt magnetic separator protects logistics equipment

RBCYD Explosion-Proof Permanent Belt Coal Conveyor Magnetic Separator Service and Support

Technical Consultation

We provide material analysis, magnetic selection advice, and system design support for belt magnetic separator and coal conveyor magnetic separator applications.

Custom Solutions

-

Adaptation to belt widths from 500mm to 2000mm

-

Custom designs for high-temperature, explosive, or corrosive environments

-

Integration with intelligent control systems and metal detectors for belt magnetic separator and coal conveyor magnetic separator

Installation & Commissioning

On-site guidance for mounting height, location, and belt tension adjustment ensures optimal performance of coal conveyor magnetic separator systems.

Training & Maintenance

Comprehensive operation manuals and maintenance guidance are provided for all belt magnetic separator installations.

After-Sales Service

-

12-month warranty

-

24-hour technical support for coal conveyor magnetic separator systems

-

Lifelong supply of spare parts including magnets, belts, and reducers for belt magnetic separator equipment

Categories

Categories