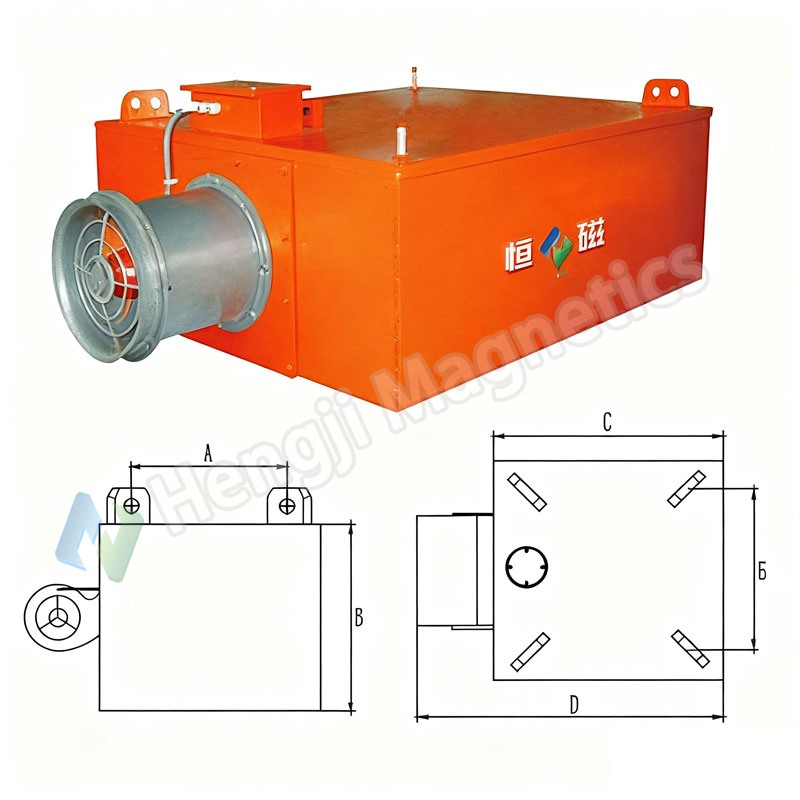

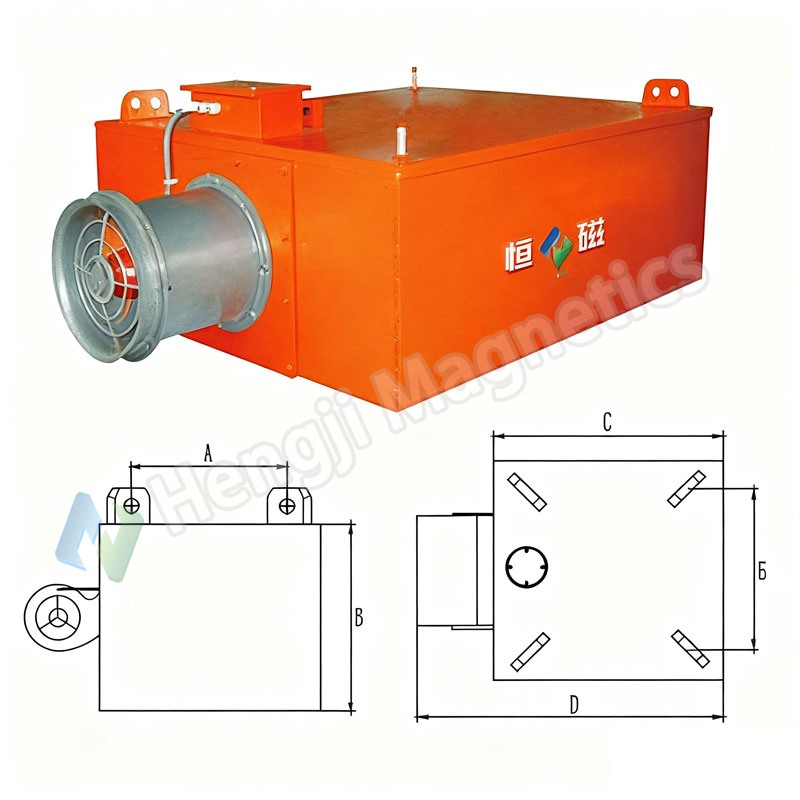

RCDA Air-cooled Industrial Electromagnet Conveyor Belt Magnetic Separator Overview

The RCDA series is an air-cooled industrial electromagnet from Weifang Hengji. This manual-cleaning conveyor belt magnetic separator uses electromagnetic excitation and forced air cooling for stable performance.

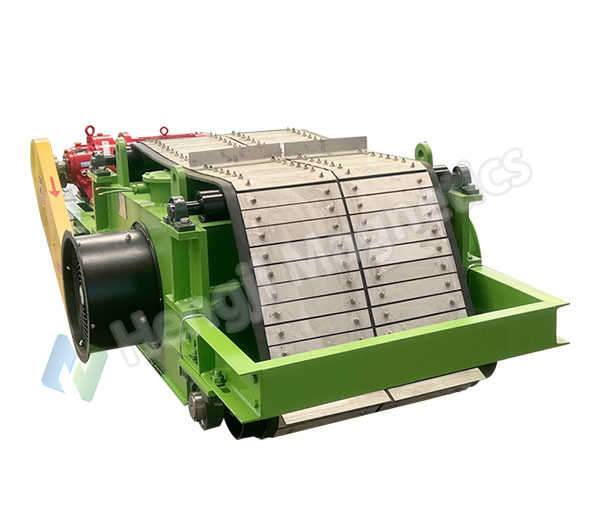

This industrial electromagnet removes ferrous impurities from bulk non-magnetic materials. It is suitable for coal, minerals, and construction materials.

Designed for power generation, mining, and metallurgy, this conveyor belt magnetic separator has a fully sealed structure. It offers excellent dust, moisture, and corrosion resistance.

This industrial electromagnet provides high magnetic field strength and deep penetration. It is ideal for small to medium-width conveyor systems.

The RCDA series conveyor belt magnetic separator protects downstream equipment like crushers. It prevents damage from tramp iron.

This industrial electromagnet ensures reliable performance in harsh environments. Its efficient cooling system maintains optimal temperature during continuous use.

RCDA Air-cooled Suspended Electromagnetic Separator Features & Benefits

Strong Magnetic Force

-

Features computer-optimized magnetic circuit design

-

Delivers 900-1500Gs magnetic strength

-

Attracts ferrous objects weighing 0.1-35kg

-

This industrial electromagnet ensures powerful separation

-

The conveyor belt magnetic separator removes iron effectively

Efficient Cooling System

-

Built-in axial fan for forced air cooling

-

Controls coil temperature rise within 80°C

-

Extends service life of this industrial electromagnet

-

Maintains consistent performance

-

The conveyor belt magnetic separator operates reliably

Energy Efficiency

-

Consumes 30% less energy than conventional separators

-

Operates below 75dB noise levels

-

Meets environmental standards

-

This industrial electromagnet reduces operational costs

-

The conveyor belt magnetic separator is eco-friendly

Robust Construction

-

Welded steel housing with anti-corrosion coating

-

Provides IP54 protection rating

-

Suitable for outdoor and dusty conditions

-

This industrial electromagnet ensures long-term reliability

-

The conveyor belt magnetic separator withstands harsh environments

Installation & Maintenance

-

Vacuum-encapsulated coils with Class F insulation

-

Reduces maintenance needs significantly

-

Supports both suspended and fixed installation

-

Accommodates belt widths from 650mm to 1400mm

-

This industrial electromagnet offers flexible setup

-

The conveyor belt magnetic separator suits various applications

RCDA Air-cooled Suspended Electromagnetic Separator Parameter Table

RCDA Air-cooled Industrial Electromagnet Conveyor Belt Magnetic Separator Working Principle

RCDA Air-cooled Industrial Electromagnet Conveyor Belt Magnetic Separator Applications

RCDA Air-cooled Industrial Electromagnet Conveyor Belt Magnetic Separator

Categories

Categories