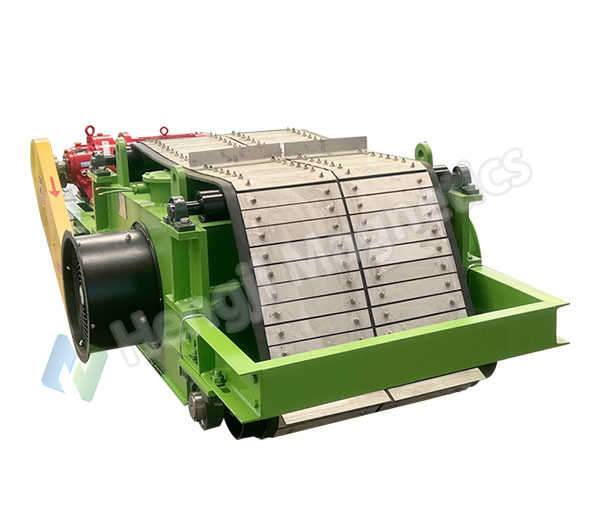

RCDB Suspended Electro Conveyor Magnet Product Overview

The RCDB series efficiently extracts ferrous contaminants from various materials. This suspended electro magnet delivers deep magnetic penetration and powerful force.

Its robust construction resists dust, moisture, and corrosion. This suspended conveyor magnet features fully sealed construction with resin potting.

It maintains stable long-term performance in challenging environments. The integrated rectifier enables precise magnetic field adjustment for this suspended electro magnet.

It optimizes separation efficiency while minimizing energy consumption. This suspended conveyor magnet is ideal for mining, metallurgy, and chemical processing.

It ensures reliable operation across various industrial scenarios. This durable suspended electro magnet is suitable for continuous use in demanding conditions.

RCDB Suspended Electro Conveyor Magnet Key Features

Powerful Magnetic Performance

-

Features a computer-optimized magnetic circuit design.

-

This provides exceptional deep penetration capability.

-

It is a key feature of this suspended electro magnet.

-

The equipment can extract ferrous contaminants weighing 0.1-50kg.

-

This effective suspended conveyor magnet handles thick material layers with ease.

-

It offers superior magnetic reach compared to standard designs.

Energy Efficient Operation

-

Comprehensive design optimization reduces power consumption by over 30%.

-

The system maintains low-noise operation for a better work environment.

-

An advanced thermal management system is integrated.

-

This system minimizes energy waste in the suspended electro magnet.

-

The overall design meets modern environmental and efficiency standards.

Durable Construction

-

The excitation coils feature high-grade Class F insulation.

-

They are protected using advanced vacuum potting technology.

-

A unique wave-finned housing is used on the suspended conveyor magnet.

-

This innovative design improves heat dissipation efficiency by 300-400%.

-

Corrosion-resistant materials are used throughout construction.

-

These features collectively ensure an extended, reliable service life.

Intelligent Control System

-

A silicon-controlled rectifier (SCR) enables precise magnetic field adjustment.

-

This precise control is a core function of the suspended electro magnet.

-

The system can automatically adapt to varying operational requirements.

-

It features a user-friendly interface for simplified operation and monitoring.

-

This enhances the usability of the suspended conveyor magnet.

Safety Compliance

-

The equipment is certified for compliance with the JB/T7689-2012 industry standard.

-

This suspended conveyor magnet operates reliably at altitudes up to 2000m.

-

Its operational temperature range is from -20℃ to +40℃.

-

It can handle ambient humidity levels of up to 90%.

-

These specifications ensure safe, reliable performance of the suspended electro magnet in diverse and challenging environments.

RCDB Suspended Electro Conveyor Magnet Working Principle

Working Principle Overview

-

The RCDB suspended electro magnet operates on electromagnetic induction principles.

-

When energized, the excitation coil generates a powerful DC magnetic field.

-

This field is concentrated through DT4 electrical pure iron pole pieces.

-

This creates a high-intensity magnetic zone directly above the conveyor system.

Magnetic Separation Process

-

As bulk materials pass beneath the magnetic zone, ferrous contaminants are extracted.

-

They are removed from the material stream and held firmly against the magnet face.

-

This extraction is the primary function of the suspended conveyor magnet.

-

The powerful magnetic field of the suspended electro magnet ensures highly effective separation.

-

Meanwhile, non-magnetic materials continue their conveyance path completely unaffected.

Iron Removal Options

-

The system offers flexible iron removal methods to suit different needs.

-

Manual Cleaning Mode: The magnetic field is de-energized to allow for contaminant removal.

-

Automated Cleaning Mode: A continuous belt system operates to remove captured iron automatically.

-

This suspended conveyor magnet design provides adaptable solutions for various applications.

-

It is suitable for standard operations as well as high-volume processing scenarios.

-

Continuous iron removal is essential in these scenarios for maintaining maximum production efficiency.

RCDB Suspended Electro Conveyor Magnet Product Parameters

RCDB Suspended Electro Conveyor Magnet Industry-Specific Applications

Power Generation Industry

-

This suspended electro magnet protects coal handling systems and crushing equipment.

-

It removes damaging tramp iron from fuel sources like coal.

-

The suspended conveyor magnet prevents costly equipment damage.

-

It ensures reliable, continuous operation in power generation facilities.

Mining and Metallurgical Operations

-

In mining, the suspended electro magnet separates contaminants.

-

It cleans processing lines for iron ore and copper ore.

-

The suspended conveyor magnet improves final product quality.

-

It achieves this through efficient ferrous material extraction in metallurgical operations.

Building Materials Production

-

It purifies raw materials like cement and limestone.

-

This suspended electro magnet protects grinding mills and processing systems from damage.

-

The suspended conveyor magnet ensures equipment longevity.

-

It also maintains high production efficiency in building materials manufacturing.

Coal and Chemical Processing

-

The suspended electro magnet removes iron from coal, fertilizers, and powdered chemicals.

-

This process significantly enhances final product quality and purity.

-

The suspended conveyor magnet provides effective contamination control.

-

This is crucial for maintaining process integrity in chemical processing applications.

Additional Applications

-

The suspended electro magnet performs critical metal separation.

-

It is used in food processing and grain handling for safety.

-

For recycling operations, the suspended conveyor magnet recovers valuable ferrous materials.

-

It supports advanced purification processes across multiple other industrial sectors.

RCDB Suspended Electro Conveyor Magnet Services

Categories

Categories