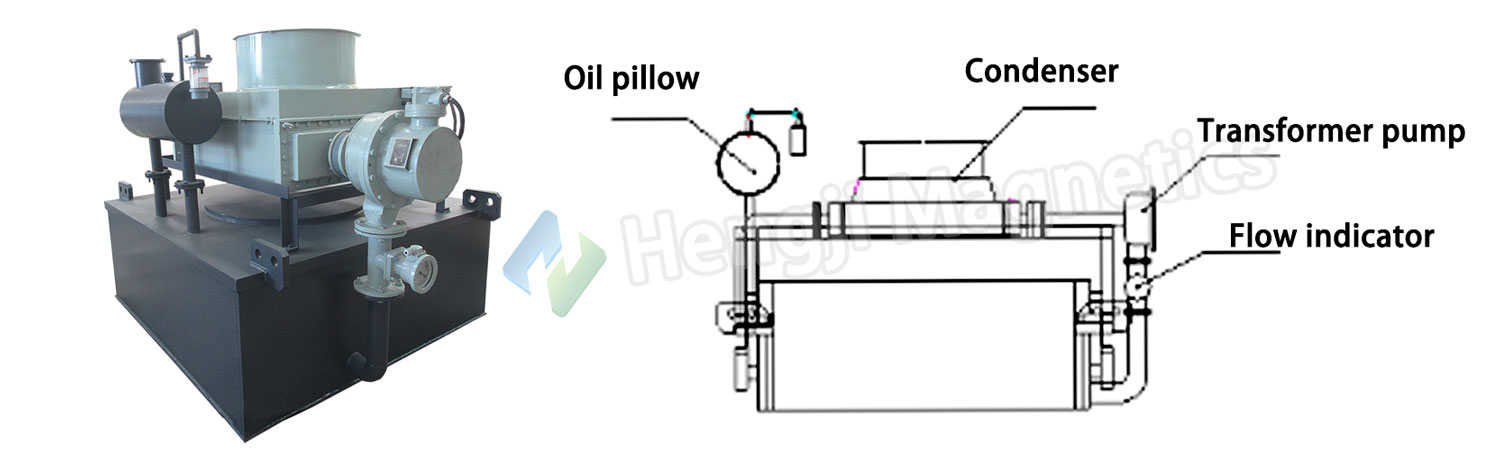

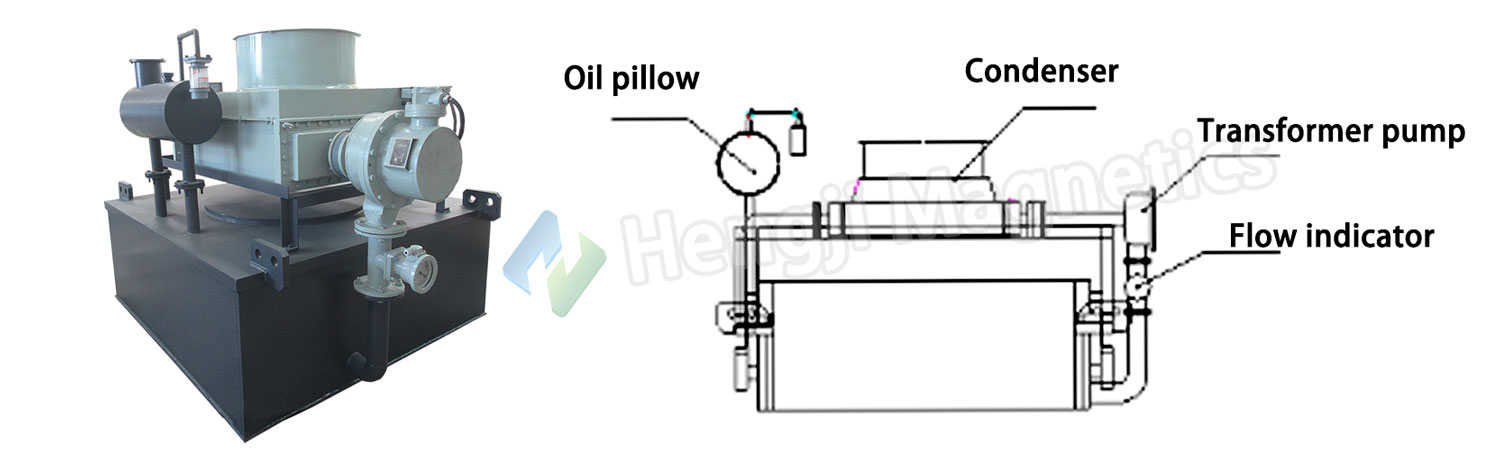

RCDEJ Force Oil Circulation Electro Suspension Disc Magnetic Separator Product Overview

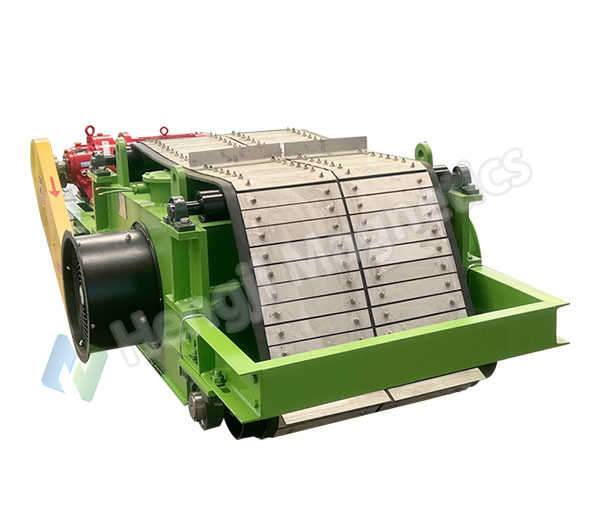

The RCDEJ Series is an advancement in electromagnetic separation technology. This high-performance electro suspension magnet extracts ferrous contaminants from bulk materials.

It utilizes optimized magnetic circuit design for exceptional separation. This robust disc magnetic separator ensures reliable operation in dusty, moist, and corrosive conditions.

Its modular architecture simplifies installation and maintenance. This versatile electro suspension magnet serves mining, metallurgy, and building materials industries.

It also supports power generation and chemical processing. This sophisticated disc magnetic separator balances powerful performance with operational efficiency.

It provides an ideal solution for consistent contaminant removal. This reliable electro suspension magnet meets demands for high processing reliability.

RCDEJ Force Oil Circulation Electro Suspension Disc Magnetic Separator Key Features

Superior Separation Capability

-

High-performance electromagnetic coils create intense magnetic fields.

-

The fields possess deep penetration power for effective cleaning.

-

The optimized magnetic circuit ensures maximum ferrous contamination removal.

-

This performance is consistent across various material depths and flow rates.

-

It is a defining feature of the electro suspension magnet.

Energy Efficient Operation

-

An advanced power management system is integrated.

-

This significantly reduces overall electricity consumption.

-

This disc magnetic separator offers lower operational costs.

-

Its efficiency is superior compared to conventional equipment.

-

The system meets stringent international energy efficiency standards.

Durable Construction

-

The excitation coils feature high-grade Class F insulation.

-

They are protected using vacuum encapsulation technology.

-

The equipment is housed in a heavy-duty, robust housing.

-

This provides exceptional impact and abrasion resistance.

-

This construction ensures the electro suspension magnet withstands the most harsh operating conditions.

Intelligent Control System

-

Advanced electronics enable stepless magnetic intensity adjustment.

-

The system features adaptive performance optimization.

-

It has a user-friendly interface for simplified operation.

-

The interface also facilitates easy monitoring.

-

These control features are central to the disc magnetic separator.

Safety Compliance

-

The equipment is certified to relevant international safety standards.

-

It operates reliably at altitudes up to 2000 meters.

-

Its operational temperature range is from -20℃ to +40℃.

-

It can handle a maximum relative humidity of 90%.

-

These specifications make the electro suspension magnet suitable for diverse and challenging environmental conditions.

RCDEJ Force Oil Circulation Electro Suspension Disc Magnetic Separator Working Principle

Working Principle Overview

-

The RCDef electro suspension magnet operates on fundamental electromagnetic principles.

-

When energized, its specialized excitation coil generates a powerful magnetic field.

-

This field is concentrated and directed through high-permeability magnetic materials.

-

This creates an intense, controlled magnetic zone.

-

The zone covers the entire working area of the equipment.

Magnetic Separation Process

-

As bulk materials transport beneath the equipment, ferrous contaminants are immediately extracted.

-

They are removed from the material flow and firmly retained against the magnet’s surface.

-

This extraction is the primary function of the advanced disc magnetic separator.

-

Meanwhile, non-magnetic materials continue through the process completely unaffected.

Iron Removal & System Design

-

The system provides flexible iron removal options for different operational needs.

-

Manual Cleaning: The magnetic field can be deactivated for contaminant removal.

-

Automated Cleaning (Optional): Features continuous belt operation for hands-free cleaning.

-

This versatile design of the electro suspension magnet enables efficient, uninterrupted processing.

-

It is suitable for various demanding industrial applications.

-

The system maintains consistent, high-performance separation throughout its operation.

RCDEJ Force Oil Circulation Electro Suspension Disc Magnetic Separator Product Parameters

RCDEJ Force Oil Circulation Electro Suspension Disc Magnetic Separator Industry Applications

Mining Operations

-

The electro suspension magnet performs critical contaminant separation.

-

It is used in iron ore and copper ore processing lines.

-

It protects expensive crushers and grinding mills from tramp iron damage.

-

This disc magnetic separator ensures operational continuity.

-

It is vital in demanding mineral extraction environments.

Metallurgical Industry

-

It enables high-grade raw material purification.

-

This process safeguards sensitive smelting equipment.

-

It enhances final product quality through precise ferrous contamination control.

-

This makes the electro suspension magnet essential for quality-focused metallurgical processes.

Building Materials Production

-

The system effectively purifies raw materials like cement and limestone.

-

It provides reliable protection for grinding and processing systems.

-

This disc magnetic separator maintains high production efficiency.

-

It operates reliably in abrasive material handling applications.

Power Generation

-

The electro suspension magnet protects entire coal handling systems.

-

It prevents damage to conveyor belts and crushing equipment.

-

This ensures uninterrupted, reliable power generation operations.

Chemical Processing

-

It removes iron contaminants from fertilizers and plastic raw materials.

-

This significantly improves final product quality in powder processing.

-

This versatile disc magnetic separator serves multiple industrial sectors.

-

It delivers consistent, high-performance separation across applications.

RCDEJ Force Oil Circulation Electro Suspension Disc Magnetic Separato Services

Custom Engineering Solutions

-

We provide tailored magnetic strength configurations.

-

These are based on your specific material characteristics and installation height.

-

Our specialized designs are for explosive atmospheres and high-temperature applications.

-

This ensures the electro suspension magnet meets your unique operational requirements.

-

The disc magnetic separator can be further engineered for specialized processing conditions.

Installation and Commissioning

-

Our technical team offers comprehensive on-site guidance.

-

This ensures the proper physical installation of the equipment.

-

Our service includes magnetic field optimization and performance verification.

-

We adjust all key operational parameters to maximize efficiency.

-

This process ensures the optimal performance of both your electro suspension magnet and disc magnetic separator.

Maintenance Support

-

We provide structured scheduled maintenance programs.

-

These include protocols for regular coil insulation testing.

-

We guarantee the supply of 100% genuine spare parts for wear components.

-

Our technical guidance covers proper replacement procedures.

-

We advise on best practices for maintaining your electro suspension magnet and disc magnetic separator.

Comprehensive Training

-

Our training programs cover fundamental equipment operational principles.

-

They include essential safety protocols and emergency response procedures.

-

We provide hands-on, practical instruction in troubleshooting techniques.

-

We also teach effective maintenance methodologies.

-

This training is specific to both the electro suspension magnet and disc magnetic separator systems.

Categories

Categories