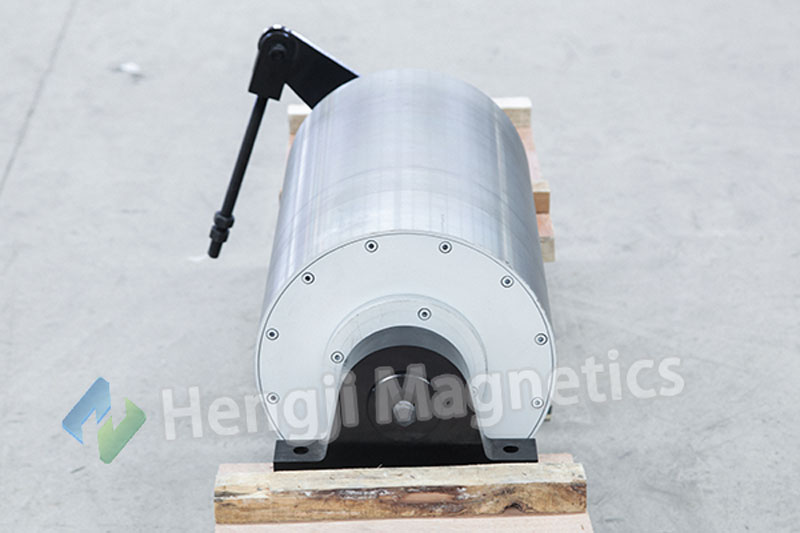

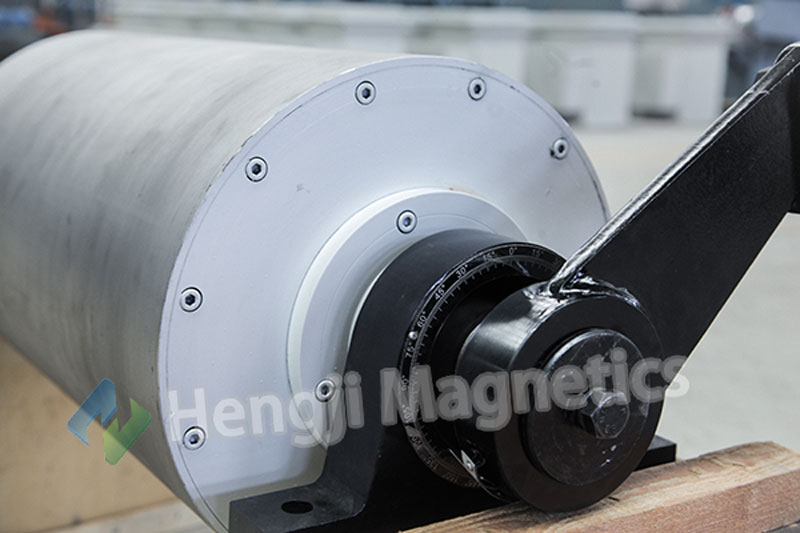

RCT Permanent Head Pulley Magnet Product Overview

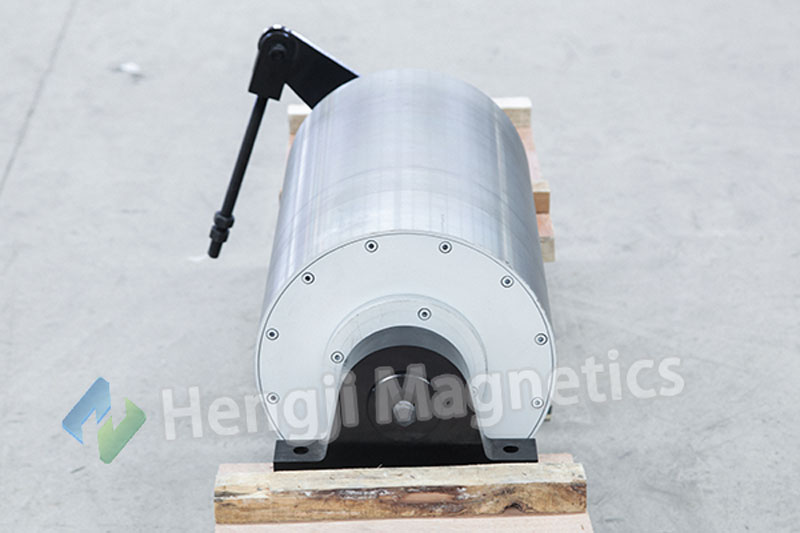

The RCT Series represents a premium line of rotating permanent magnetic separation equipment, engineered with a high-performance permanent magnetic core system. This advanced permanent magnetic pulley serves dual functions as both an efficient magnetic separator and a reliable drive mechanism in material handling systems.

Designed for high efficiency and true maintenance-free operation, this robust head pulley magnet delivers extended service life and significant energy savings. As an ISO9001 certified product from a nationally recognized high-tech enterprise, the RCT series has proven its reliability across multiple industries including cement, mining, steel, building materials, grain processing, and waste management. This versatile permanent magnetic pulley provides trusted performance for magnetic separation and tramp iron removal applications in demanding operational environments.

RCT Permanent Head Pulley Magnet Key Features

High-Performance Magnetic Core

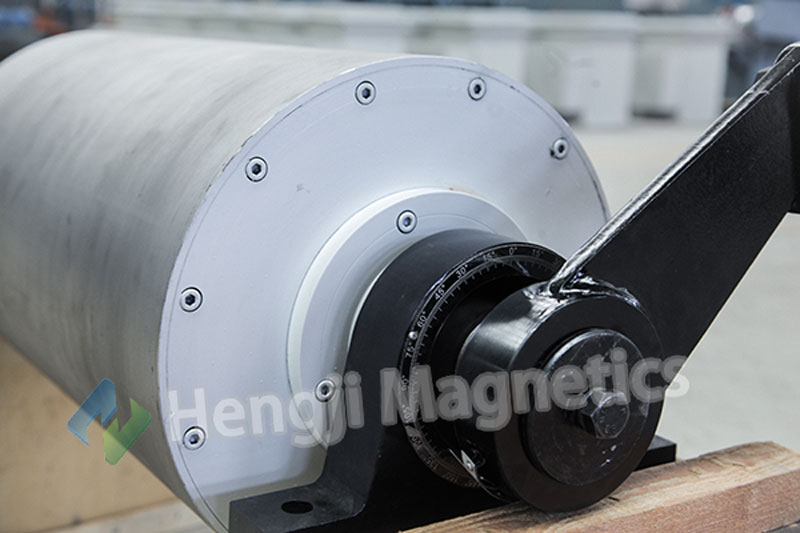

The head pulley magnet features an internal NdFeB magnetic system generating strong, stable magnetic fields. With minimal annual demagnetization and an eight-year warranty, this permanent magnetic pulley ensures reliable performance and over a decade of service life.

Configurable Magnetic Strength

Standard models (150-250 mT) and special types (300-400 mT+) are available, with custom configurations up to 5500 Gauss. This flexibility allows the permanent magnetic pulley to meet diverse separation requirements.

Robust Construction

Stainless steel drum construction with optional polished or rubber-covered surfaces makes this head pulley magnet highly durable. Various rubber patterns enhance traction and wear resistance for different conveying applications.

Efficient Operation

The permanent magnetic pulley requires zero electrical power, delivering significant energy savings and maintenance-free operation. Its simple, robust structure ensures easy installation and reliable performance as a conveyor drive roller.

Superior Separation

Excelling where suspended separators struggle, this head pulley magnet effectively removes deeply buried ferrous contaminants, achieving thorough material purification in demanding industrial environments.

RCT Permanent Head Pulley Magnet Working Principle

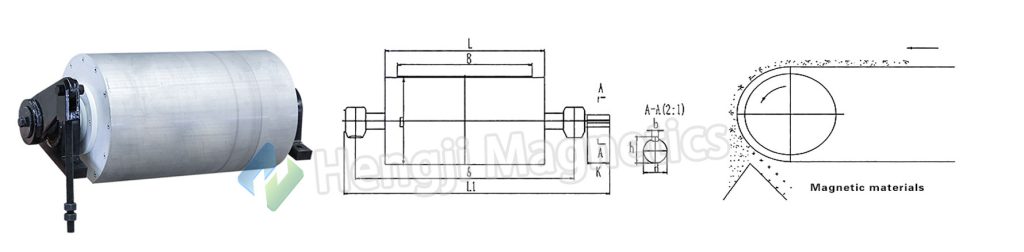

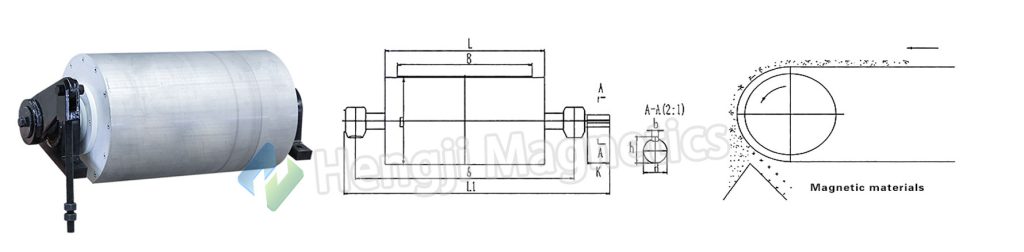

The RCT permanent magnetic pulley operates on magnetic separation principles, leveraging differences in material magnetic susceptibility. As bulk material enters the separation zone of this head pulley magnet, particles experience both magnetic and mechanical forces.

Non-magnetic materials follow their natural trajectory off the pulley head, while strongly magnetic particles are firmly held to the rotating surface. The permanent magnetic pulley carries captured ferrous materials beyond the magnetic field where they discharge via gravity and centrifugal force into collection chutes. This head pulley magnet ensures continuous, efficient separation by systematically dividing material streams based on magnetic properties.

RCT Permanent Head Pulley Magnet Product Parameters

-

|

Model

|

Max. Magnetic Field Intensity in Brief Table (GS)

|

Max. Belt Speed (≤m/s)

|

Max. Material Thickness (≤mm)

|

Weight (kg)

|

Overall Dimensions (mm)

|

|

|

|

4.5

|

|

|

A

|

B

|

DØ

|

L

|

L1

|

K

|

dØ

|

h

|

b

|

|

RCT-32/40

|

1500~8000

|

40

|

150

|

728

|

400

|

320

|

500

|

962

|

100

|

45

|

48.5

|

14

|

|

RCT-32/50

|

1500~8000

|

60

|

198

|

850

|

500

|

320

|

600

|

1097

|

115

|

50

|

53.5

|

14

|

|

RCT-40/50

|

1500~8000

|

80

|

250

|

850

|

500

|

400

|

600

|

1097

|

115

|

55

|

60

|

16

|

|

RCT-50/50

|

1500~8000

|

100

|

370

|

850

|

500

|

500

|

600

|

1097

|

115

|

55

|

60

|

16

|

|

RCT-32/65

|

1500~8000

|

70

|

205

|

910

|

650

|

320

|

750

|

1280

|

135

|

65

|

69

|

18

|

|

RCT-40/65

|

1500~8000

|

100

|

405

|

1000

|

650

|

400

|

750

|

1280

|

135

|

65

|

69

|

18

|

|

RCT-50/65

|

1500~8000

|

130

|

520

|

1000

|

650

|

500

|

750

|

1280

|

135

|

70

|

76

|

20

|

|

RCT-50/80

|

1500~8000

|

100

|

610

|

1300

|

800

|

500

|

950

|

1580

|

135

|

70

|

76

|

20

|

|

RCT-65/80

|

1500~8000

|

130

|

720

|

1300

|

800

|

650

|

950

|

1661

|

175

|

70

|

76

|

20

|

|

RCT-65/80

|

1500~8000

|

150

|

980

|

1300

|

800

|

650

|

950

|

1661

|

175

|

90

|

97

|

24

|

|

RCT-80/100

|

1500~8000

|

130

|

710

|

1300

|

1000

|

800

|

1150

|

1861

|

175

|

90

|

97

|

24

|

|

RCT-80/100

|

1500~8000

|

170

|

1200

|

1500

|

1000

|

800

|

1150

|

1954

|

215

|

90

|

97

|

24

|

|

RCT-65/120

|

1500~8000

|

100

|

1500

|

1750

|

1200

|

650

|

1400

|

2195

|

215

|

110

|

119

|

32

|

|

RCT-100/120

|

1500~8000

|

200

|

1890

|

1750

|

1200

|

1000

|

1400

|

2270

|

255

|

110

|

119

|

32

|

|

RCT-100/140

|

1500~8000

|

230

|

2160

|

2000

|

1400

|

1000

|

1600

|

2445

|

255

|

110

|

119

|

32

|

|

RCT-125/160

|

1500~8000

|

260

|

2800

|

2150

|

1600

|

1250

|

1800

|

2600

|

255

|

120

|

129

|

32

|

RCT Permanent Head Pulley Magnet Applications

The RCT permanent magnetic pulley serves diverse industrial sectors requiring continuous ferrous removal from dry bulk materials. This versatile head pulley magnet delivers reliable performance across multiple applications.

Core Application Sectors

In cement production, the permanent magnetic pulley protects crushers and grinding mills while enhancing final product quality. Mining operations utilize this head pulley magnet for iron ore pre-concentration and non-metallic mineral purification. The equipment serves steel plants for slag processing and protects raw material handling systems in metallurgical applications.

Extended Industrial Sectors

The permanent magnetic pulley ensures operational safety in coal processing by removing hazardous metals. Grain and feed facilities rely on this head pulley magnet for product purity and equipment protection. Chemical plants and waste recycling operations benefit from its material purification and metal recovery capabilities, making the permanent magnetic pulley essential for modern industrial processes.

RCT Permanent Head Pulley Magnet Services and Support

Expert Selection Guidance

We assist in selecting the correct permanent magnetic pulley diameter and magnetic strength for your application. Key specifications include rubber covering type, rotation direction (critical for herringbone patterns), and material temperature (standard ≤80°C or high-temperature models).

Installation & Adjustment

Detailed instructions cover installation as a standalone unit or integrated as a head pulley magnet in conveyor systems. Proper alignment – ensuring the pulley centerline is parallel to the horizontal plane and perpendicular to material flow – is essential for optimal performance of your permanent magnetic pulley.

Unique Quality Assurance

Our distinctive “Workshop Worker Responsibility System” provides exceptional warranty protection. Within the one-year period, if manufacturing defects occur, the original assembly technicians will be dispatched to resolve issues at their own expense, ensuring direct accountability and reliable performance of your head pulley magnet.

Categories

Categories