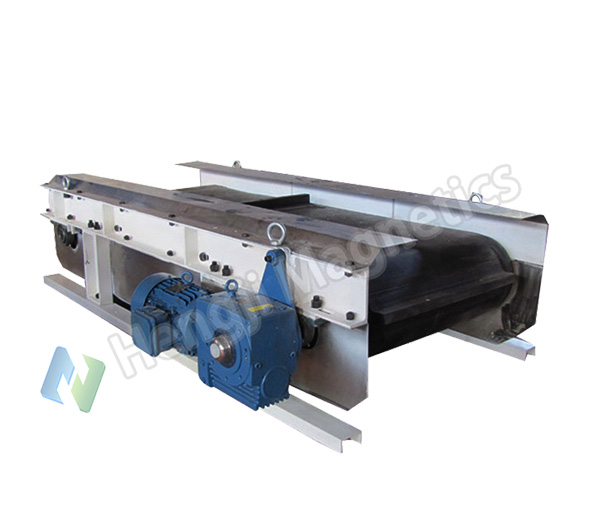

RCYE Overhead Recycling Magnetic Separator Product Overview

The RCYE series represents a significant advancement in permanent magnetic separation technology, designed for efficient extraction of ferrous contaminants from bulk materials. This robust overhead magnetic separator utilizes high-performance rare-earth magnets to generate powerful magnetic fields without electrical consumption, ensuring energy-efficient operation with minimal maintenance requirements.

As a versatile recycling magnetic separator, the series features automated cleaning mechanisms for continuous operation in demanding environments. Its compact design enables flexible installation above conveyor head pulleys or along intermediate sections, providing reliable tramp iron protection. Proven across power generation, mining, and building materials sectors, this overhead magnetic separator delivers long-term value through zero energy consumption and low operational costs, while the recycling magnetic separator configuration excels in material recovery applications.

RCYE Overhead Recycling Magnetic Separator Key Features

High-Efficiency Magnetic System

This overhead magnetic separator employs high-grade NdFeB rare-earth magnets with scientifically optimized magnetic circuits, delivering strong surface intensity and deep penetration. Effective for material layers up to 350mm, this recycling magnetic separator maintains stable performance throughout its extended service life.

Automated Cleaning Mechanism

The turbine worm reducer drive ensures smooth operation, while specialized scraper blades provide complete contaminant removal. This overhead magnetic separator features continuous self-cleaning with online adjustable belt tension, making the recycling magnetic separator ideal for uninterrupted operation.

Optimized Structural Design

Featuring a compact configuration with wear-resistant components, this overhead magnetic separator minimizes space requirements. The comprehensive protective cover and accessible bearing adjustment system enhance the recycling magnetic separator‘s durability while reducing maintenance downtime.

Eco-Friendly Operation

The permanent magnet operation requires no electrical power, eliminating oil contamination and emissions. This overhead magnetic separator delivers low-noise performance, while the recycling magnetic separator configuration supports sustainable operations through energy-efficient material recovery.

RCYE Overhead Recycling Magnetic Separator Working Principle

The RCYE recycling magnetic separator operates through an integrated system of permanent magnetic attraction and automated mechanical conveying, ensuring efficient ferrous material extraction and continuous operation.

Magnetic Attraction Phase

The permanent magnetic system generates a high-intensity magnetic field concentrated at the bottom of this overhead magnetic separator. As bulk materials transport beneath the equipment, ferrous contaminants are instantly extracted from the material flow. The powerful magnetic force securely adheres captured metals to the cleaning belt surface, while non-magnetic materials continue unaffected along the conveyor path. This efficient recycling magnetic separator effectively processes various material streams without requiring electrical power for its magnetic functions.

Automatic Discharge Process

A turbine worm reducer drives continuous operation of the active roller, powering the cleaning belt’s movement. The system transports captured ferrous materials toward the discharge area, where specially designed scrapers efficiently remove contaminants into collection containers. This automated cycle in the overhead magnetic separator ensures uninterrupted cleaning operation, making the recycling magnetic separator ideal for continuous production environments where minimal manual intervention is desired.

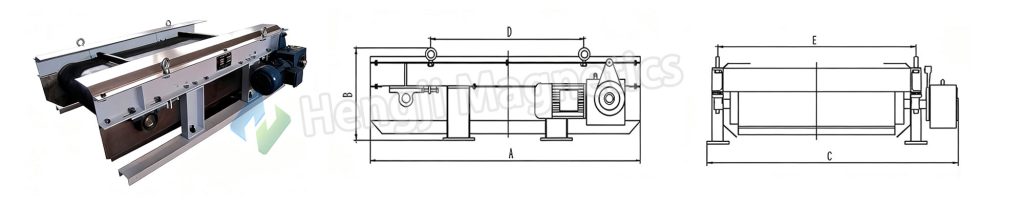

RCYE Overhead Recycling Magnetic Separator Product Parameters

|

Model

|

Applicable Belt Width (mm)

|

Rated Lifting Height (mm)

|

Magnetic Field Intensity (mT)

|

Material Thickness (≤mm)

|

Weight (kg)

|

Overall Dimensions (mm)

|

|

|

|

|

|

|

|

A

|

B

|

C

|

D

|

E

|

|

RCYE-6

|

650

|

175

|

70

|

120

|

1150

|

1492

|

380

|

1100

|

772

|

875

|

|

RCYE-8

|

800

|

250

|

70

|

200

|

1300

|

1712

|

380

|

1319

|

972

|

1080

|

|

RCYE-10

|

1000

|

300

|

70

|

250

|

1400

|

1882

|

380

|

1338

|

1122

|

1180

|

|

RCYE-12

|

1200

|

350

|

70

|

300

|

1650

|

2102

|

380

|

1538

|

1270

|

1308

|

|

RCYE-14

|

1400

|

400

|

70

|

350

|

1900

|

2300

|

380

|

1735

|

1400

|

1500

|

RCYE Overhead Recycling Magnetic Separator Applications

Primary Industry Applications

The overhead magnetic separator provides essential protection in thermal power plant coal handling systems and mining operations for pre-crushing iron removal. This versatile recycling magnetic separator serves metallurgical plants for raw material purification and building materials facilities for cement production. The equipment also handles coal preparation, chemical processing, and various industrial applications requiring efficient ferrous contamination control.

Typical Installation Positions

The overhead magnetic separator typically installs above belt conveyor drive pulleys at head sections or along intermediate conveyor runs. This flexible recycling magnetic separator also integrates with vibrating feeder systems and operates effectively at critical transfer points, providing comprehensive protection throughout material handling processes.

Suitable Material Characteristics

This overhead magnetic separator effectively removes ferrous contaminants from bulk non-magnetic materials with substantial depth. The automated recycling magnetic separator excels in continuous processing lines where consistent performance and minimal intervention are essential, handling various material streams while maintaining operational efficiency.

RCYE Overhead Recycling Magnetic Separator Services

Technical Consultation

We provide customized separation solution design for your overhead magnetic separator, including equipment selection and parameter optimization. Our experts offer comprehensive installation position and process layout guidance to ensure your recycling magnetic separator integrates seamlessly into existing operations.

Installation Support

Detailed foundation drawings and installation requirements are provided for the overhead magnetic separator. We deliver on-site installation guidance with technical coordination, plus complete commissioning and trial operation support for your recycling magnetic separator system.

Operation Training

Comprehensive training covers equipment principles and operational procedures for both the overhead magnetic separator and recycling magnetic separator. We provide essential maintenance knowledge and troubleshooting methodologies to ensure optimal equipment performance.

After-Sales Support System

Our comprehensive quality assurance includes genuine spare parts supply and rapid technical response for the overhead magnetic separator. We offer regular equipment evaluation and maintenance reminders to keep your recycling magnetic separator operating at peak efficiency throughout its service life.

Categories

Categories