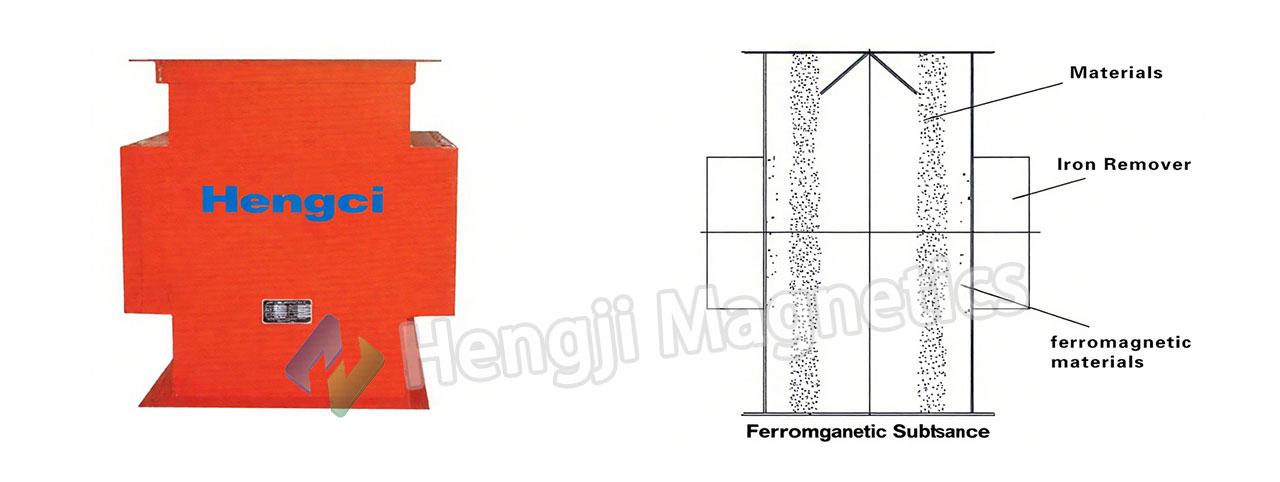

RCYF Vertical Grain Pipeline Magnetic Filter Separator Product Overview

The RCYF Pipeline Permanent Magnetic Separator represents advanced magnetic separation technology for vertical installation in powder and granular material processing systems. This innovative pipeline filter separator utilizes high-performance rare-earth NdFeB permanent magnets to deliver exceptional iron removal efficiency with zero energy consumption during operation.

As a specialized grain magnetic separator, the RCYF series handles diverse material types while requiring minimal installation space. The vertical design enables seamless integration into existing conveying systems without process modifications. Certified under ISO9001 standards, this versatile pipeline filter separator serves cement, building materials, chemicals, food processing, and plastics industries, providing reliable magnetic protection in space-constrained environments while maintaining production efficiency and product purity.

RCYF Vertical Grain Pipeline Magnetic Filter Separator Key Features

Compact Structural Design

The vertical configuration of this pipeline filter separator minimizes footprint while allowing direct connection to existing pipelines. This space-efficient grain magnetic separator adapts to various layouts, ideal for facilities with limited installation space.

High-Efficiency Iron Removal

Utilizing rare-earth NdFeB permanent magnets, this pipeline filter separator delivers strong magnetic intensity for effective contaminant adsorption. The persistent magnetic force ensures reliable operation of this grain magnetic separator throughout its lifespan.

Zero Energy Consumption

Operating with permanent magnet technology, this pipeline filter separator requires no electrical power. The true zero-energy operation of this grain magnetic separator significantly reduces costs while meeting environmental standards.

Durability & Maintenance

Featuring a fully sealed structure, this pipeline filter separator prevents dust ingress and leakage. The modular design of this grain magnetic separator enables quick cleaning, while corrosion-resistant materials ensure extended service life in demanding environments.

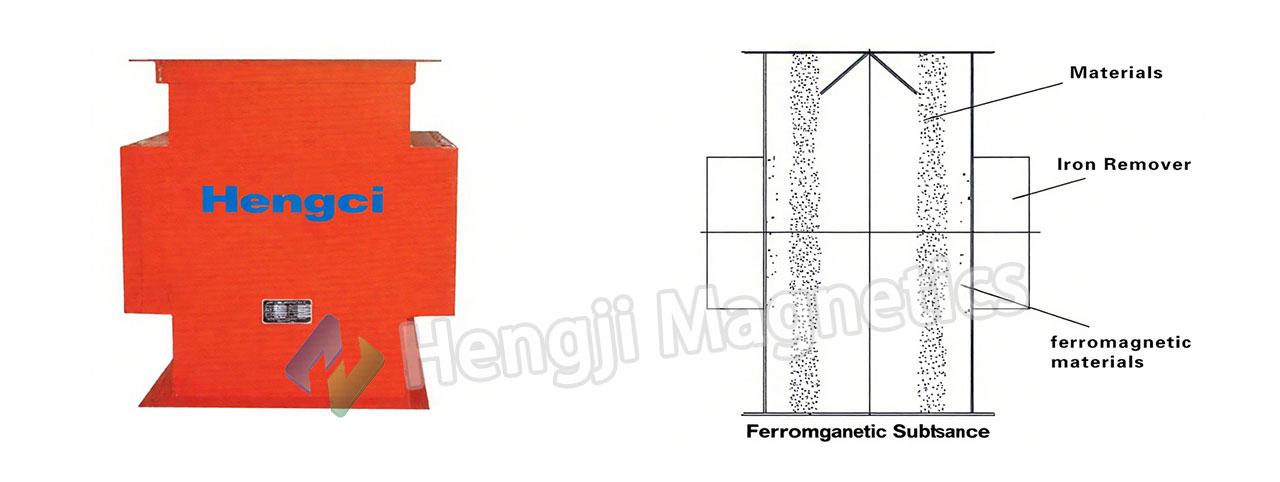

RCYF Vertical Grain Pipeline Magnetic Filter Separator Working Principle

The RCYF pipeline filter separator operates through permanent magnetic adsorption technology to efficiently remove ferrous contaminants from material streams. This advanced grain magnetic separator utilizes a powerful permanent magnetic system that generates a high-intensity magnetic field within its vertically installed pipeline configuration.

Magnetic Separation Process

When materials containing ferrous particles pass through the pipeline filter separator, the magnetic system immediately extracts and securely holds contaminants against specially designed areas of the pipeline’s inner wall. The cleaned materials continue uninterrupted through the conveying system, while this effective grain magnetic separator maintains constant magnetic force without requiring external energy input.

Operation and Maintenance

The captured ferrous materials accumulate within the pipeline filter separator until removed through simple manual or mechanical cleaning procedures. This practical design allows the grain magnetic separator to provide continuous iron removal while maintaining uninterrupted material flow, making it an ideal solution for processing systems where operational efficiency and minimal maintenance are essential requirements.

RCYF Vertical Grain Pipeline Magnetic Filter Separator Product Parameters

|

Model

|

Applicable Capacity (T/h)

|

Duct Dimensions (L×W×H, mm)

|

Permanent Magnet Dimensions (L×W×H, mm)

|

Flange Interface Dimensions (L×W, mm)

|

Installation Method

|

Weight (kg)

|

|

RCYF-15

|

15

|

300×300×600

|

300×250×80

|

360×360

|

Suitable for 90° vertical duct installation

|

105

|

|

RCYF-30

|

30

|

400×400×700

|

400×300×85

|

460×460

|

195

|

|

RCYF-50

|

50

|

500×500×800

|

500×400×85

|

600×600

|

310

|

|

RCYF-100

|

100

|

600×600×1000

|

600×450×180

|

700×700

|

470

|

|

RCYF-200

|

200

|

700×700×1200

|

700×500×210

|

840×840

|

680

|

|

RCYF-300

|

300

|

800×800×1400

|

800×700×210

|

940×940

|

890

|

|

RCYF-500

|

500

|

900×900×1500

|

900×800×250

|

1040×1040

|

1100

|

|

RCYF-600

|

600

|

1000×1000×1600

|

1000×800×250

|

1140×1140

|

1310

|

|

RCYF-800

|

800

|

1100×1100×1700

|

1100×900×250

|

1240×1240

|

1560

|

|

RCYF-1000

|

1000

|

1200×1200×1800

|

1200×1000×300

|

1340×1340

|

1820

|

|

RCYF-1500

|

1500

|

1300×1300×2000

|

1300×1100×300

|

1440×1440

|

2060

|

RCYF Vertical Grain Pipeline Magnetic Filter Separator Applications

Building Materials & Chemical Industries

The RCYF pipeline filter separator effectively removes iron from cement raw materials, clinker, and slag, preventing equipment damage while improving product quality. In chemical processing, this reliable grain magnetic separator purifies plastic pellets and raw materials, ensuring product purity and protecting production equipment.

Food Processing & Coal Industries

This hygienic pipeline filter separator guarantees food safety through grain and flour purification, complying with strict hygiene standards. The efficient grain magnetic separator also serves coal processing by removing ferrous contaminants from raw coal, improving combustion efficiency while preventing equipment damage.

Refractory Materials & General Applications

The versatile pipeline filter separator enhances refractory material quality by removing iron contaminants from raw materials and finished products. This durable grain magnetic separator ensures performance stability across various industrial applications where reliable iron removal and equipment protection are essential requirements.

RCYF Vertical Grain Pipeline Magnetic Filter Separator Services

Installation Guidance

We provide detailed installation diagrams and technical support for the pipeline filter separator, ensuring proper pipeline connections with leak-proof flange gaskets. Our comprehensive setup ensures optimal performance of your grain magnetic separator system.

Operation Training

Complete operational training covers correct procedures and safety precautions for the pipeline filter separator. We provide cleaning cycle guidance and efficiency optimization for your grain magnetic separator, ensuring best practices and equipment understanding.

Maintenance Support

Scheduled maintenance programs include cleaning and inspection of the pipeline filter separator. We offer preventive maintenance planning and performance optimization for your grain magnetic separator system.

Technical Support & Quality Assurance

Our service hotline provides immediate consultation for the pipeline filter separator. We ensure compliance with industry standards and long-term reliability of your grain magnetic separator through continuous technical support.

Categories

Categories