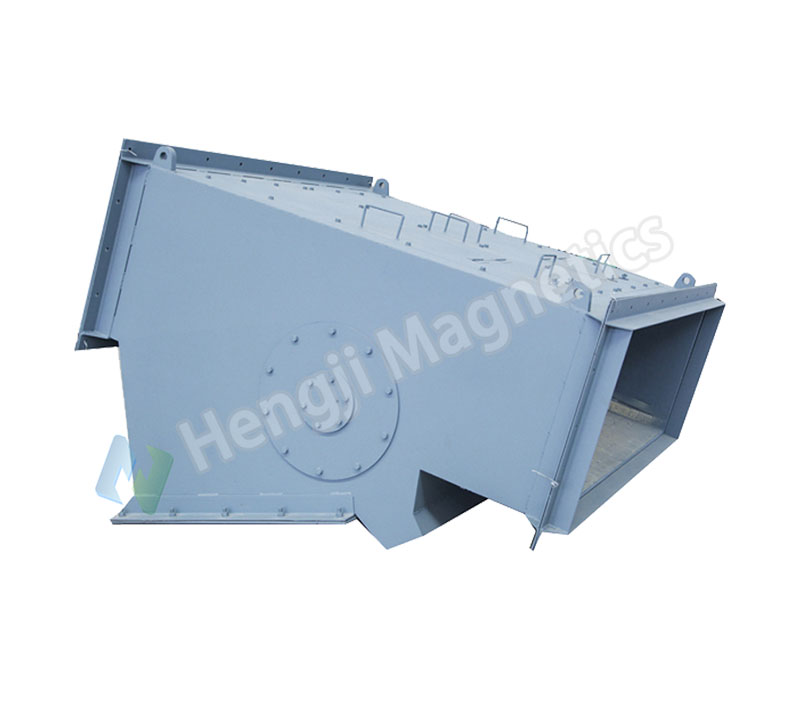

RCYG Self Cleaning Pipeline Aggregate Magnetic Separator Product Overview

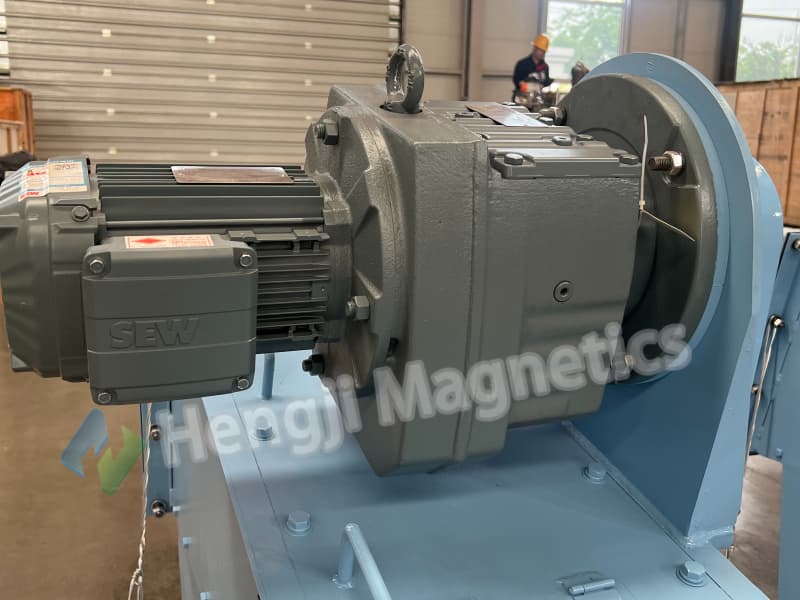

The RCYG series represents advanced automated magnetic separation technology for efficient iron removal in powder processing systems. This innovative pipeline magnetic separator features patented designs that ensure reliable performance when installed at bucket elevator discharge points, effectively preventing equipment blockage by automatically removing iron contaminants from material flows.

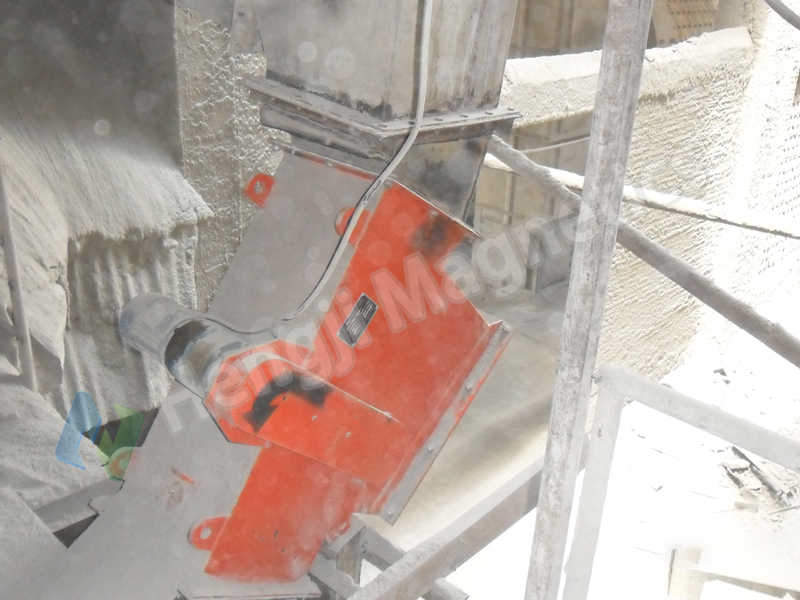

As a versatile aggregate magnetic separator, the RCYG series serves multiple industries including cement, ceramics, building materials, chemicals, and food processing. The permanent magnetic design eliminates continuous power requirements for magnetic functions, significantly reducing operational costs. This compact pipeline magnetic separator offers flexible configuration options, providing ideal solutions for enhancing product purity while protecting downstream equipment from ferrous contamination damage.

RCYG Self Cleaning Pipeline Aggregate Magnetic Separator Key Features

High-Efficiency Iron Removal

This advanced pipeline magnetic separator utilizes high-temperature resistant NdFeB magnets in multiple moving groups for comprehensive iron capture. The versatile aggregate magnetic separator handles particles from ≤10mm to 180mm at temperatures up to 125°C, ensuring consistent product quality and equipment protection.

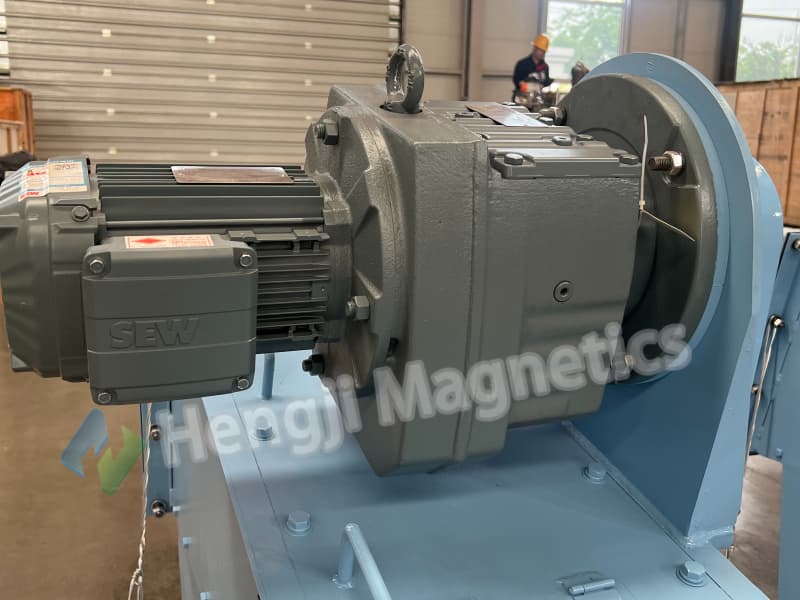

Intelligent Automated Design

Featuring fully automated operation, this pipeline magnetic separator enables 24-hour continuous iron removal without manual supervision. The integrated discharge system of this aggregate magnetic separator minimizes material loss while maintaining consistent performance through self-monitoring operation.

Energy-Saving & Environmental Protection

Utilizing permanent magnets as the adsorption source, this pipeline magnetic separator significantly reduces power consumption through intermittent discharge operation. The compact aggregate magnetic separator incorporates an integrated negative pressure system for effective dust control, meeting modern environmental standards.

Durable Structure & Easy Maintenance

With completely sealed magnetic mechanisms and wear-resistant linings, this pipeline magnetic separator ensures long-term reliability. The aggregate magnetic separator features direct pipeline connection, customizable dimensions, and accessible design for minimal maintenance requirements.

RCYG Self Cleaning Pipeline Aggregate Magnetic Separator Working Principle

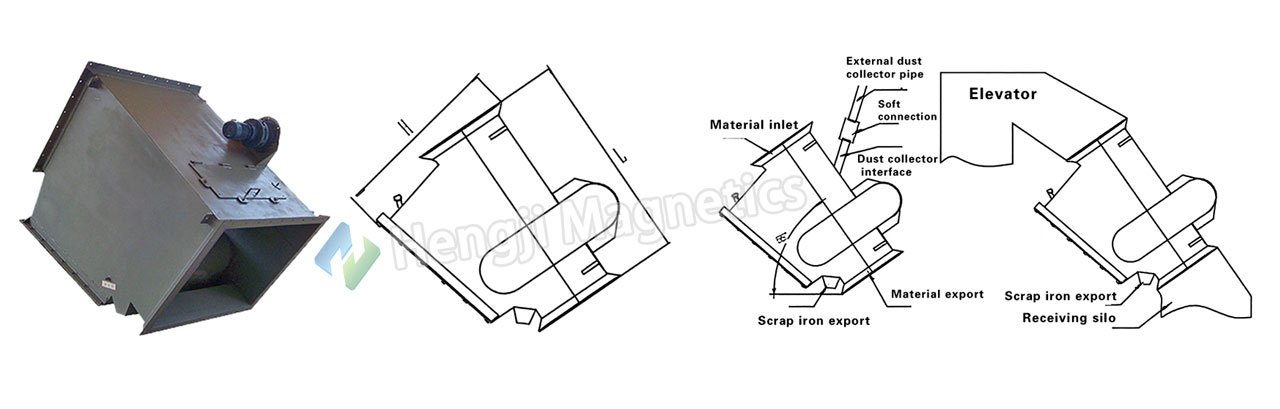

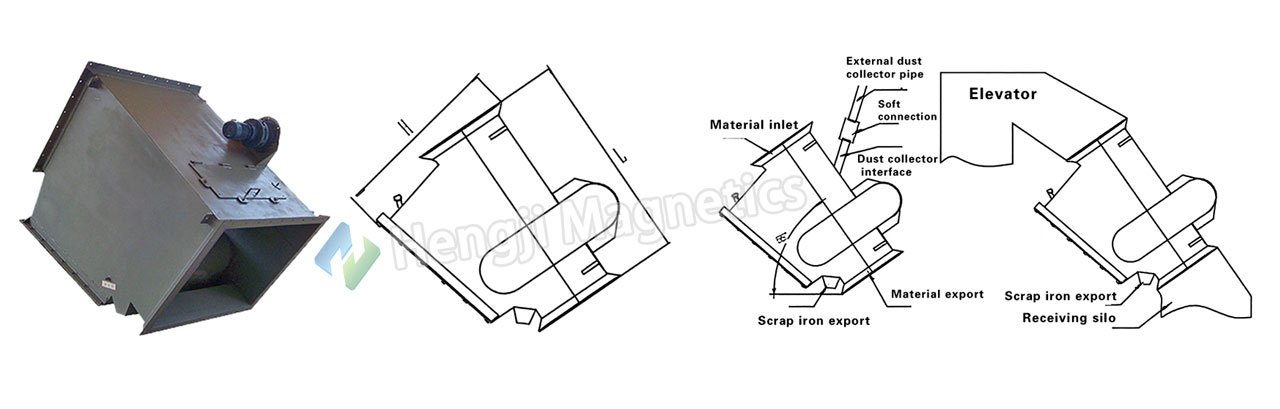

The RCYG pipeline magnetic separator operates through an efficient magnetic separation process, typically installed at a 55°-60° inclination within material conveying systems. This versatile aggregate magnetic separator effectively separates ferrous contaminants from material flows through a carefully engineered operational sequence.

Magnetic Separation Phase

As materials pass through the separator, powder flows by inertia while ferrous contaminants are extracted and held on the pipeline bottom by powerful magnetic forces. The continuous movement of the magnetic assembly in this pipeline magnetic separator transports captured materials to the separation point, where non-magnetic components continue their trajectory unaffected.

Material Discharge Process

Ferrous materials carried by magnetic movement reach the concealed discharge outlet in this aggregate magnetic separator. When the magnetic assembly reverses direction, these materials lose magnetic attraction and discharge through gravitational force. The integrated negative pressure system, compatible with external dust collection, ensures clean operation of this pipeline magnetic separator throughout the separation cycle.

RCYG Self Cleaning Pipeline Aggregate Magnetic Separator Product Parameters

|

Model

|

Optimal Throughput (T/h)

|

Max Throughput (T/h)

|

Max Removable Iron Particle Size (mm, adjustable)

|

Motor Power (kw)

|

Weight (kg)

|

Overall Dimensions (L×W×H, mm)

|

Interface Dimensions (A×A, mm)

|

|

RCYG-30

|

30

|

50

|

≤30 adjustable

|

0.37

|

160

|

950×450×850

|

300×300

|

|

RCYG-50

|

50

|

80

|

≤50 adjustable

|

0.37

|

280

|

1000×400×900

|

350×350

|

|

RCYG-100

|

100

|

150

|

≤60 adjustable

|

0.37

|

430

|

1100×510×970

|

400×400

|

|

RCYG-150

|

150

|

200

|

≤60 adjustable

|

0.55

|

510

|

1250×610×1070

|

500×500

|

|

RCYG-200

|

200

|

300

|

≤100 adjustable

|

0.55

|

620

|

1400×740×1380

|

600×600

|

|

RCYG-300

|

300

|

500

|

≤120 adjustable

|

0.55

|

890

|

1500×840×1470

|

700×700

|

|

RCYG-400

|

400

|

800

|

≤140 adjustable

|

0.75

|

1270

|

1700×950×1580

|

800×800

|

|

RCYG-500

|

500

|

1000

|

≤150 adjustable

|

0.75

|

1560

|

1800×950×1780

|

1000×800

|

|

RCYG-600

|

600

|

1200

|

≤160 adjustable

|

1.5

|

2150

|

2000×1240×1910

|

1100×900

|

|

RCYG-700

|

700

|

1400

|

≤160 adjustable

|

1.5

|

2340

|

2000×1340×2010

|

1200×1000

|

|

RCYG-800

|

800

|

1600

|

≤180 adjustable

|

1.5

|

2610

|

2100×1440×2110

|

1300×1100

|

|

RCYG-900

|

900

|

1800

|

≤180 adjustable

|

1.5

|

2800

|

2200×1540×2210

|

1400×1200

|

|

RCYG-1000

|

1000

|

2000

|

≤180 adjustable

|

1.5

|

3290

|

2400×1640×2310

|

1500×1300

|

|

RCYG-1500

|

1500

|

2200

|

≤200 adjustable

|

2.2

|

4000

|

2500×1740×2410

|

1600×1400

|

RCYG Self Cleaning Pipeline Aggregate Magnetic Separator Applications

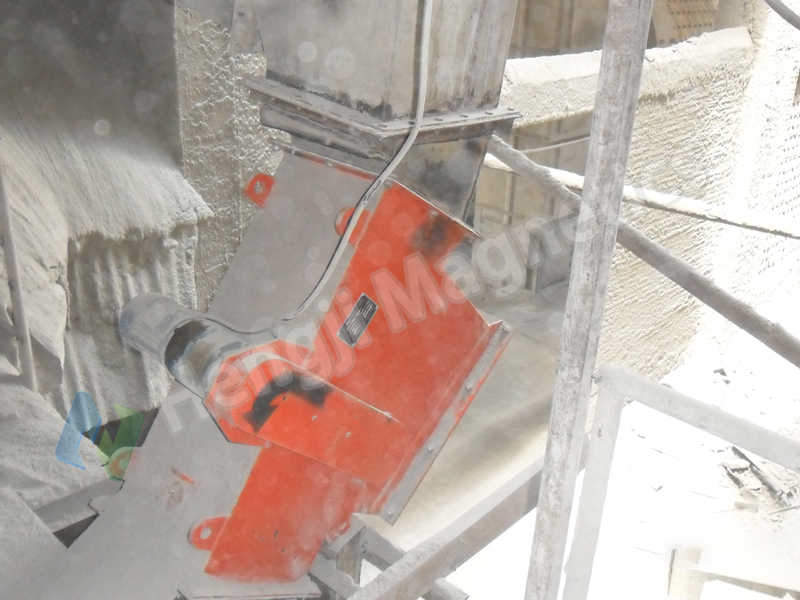

Primary Industry Applications

The RCYG pipeline magnetic separator prevents equipment failures and improves product purity in cement production. This versatile aggregate magnetic separator serves ceramics and building materials for raw material purification, while ensuring safety compliance in chemical and food processing. The equipment provides essential protection in power and metallurgy sectors, enhancing production efficiency.

Applicable Material Range

This efficient pipeline magnetic separator handles cement powder, slag, and various powdered non-magnetic materials. The aggregate magnetic separator operates within temperature ranges from ≤45°C to 125°C (depending on model), accommodating diverse industrial materials and processing conditions.

Installation Environment Requirements

Requiring 55°-60° pipeline inclination to prevent leakage, this pipeline magnetic separator operates with pipeline negative pressure ≥-50Pa. The aggregate magnetic separator functions in ambient temperatures ≤45°C, with indoor installation recommended or weather protection necessary for outdoor applications.

RCYG Self Cleaning Pipeline Aggregate Magnetic Separator Services

Professional Technical Support

We provide detailed installation manuals and technical guidance for the pipeline magnetic separator, ensuring proper installation angles and pipeline connections. Our experts offer immediate problem resolution during setup for your aggregate magnetic separator system.

Installation & Commissioning

Our team guides correct integration within powder conveying systems for the pipeline magnetic separator. We assist with pipeline inclination adjustment (55°-60°) and negative pressure setup to optimize your aggregate magnetic separator performance.

Maintenance Guidance

Regular inspection protocols maintain the pipeline magnetic separator‘s magnetic efficiency. We provide cleaning procedures for accumulated ferrous materials and seal condition checks to ensure your aggregate magnetic separator operates without leakage issues.

After-Sales Service

Our comprehensive service network supports the pipeline magnetic separator with prompt technical assistance. We offer wear parts replacement guidance and 24/7 troubleshooting services for your aggregate magnetic separator system.

Categories

Categories