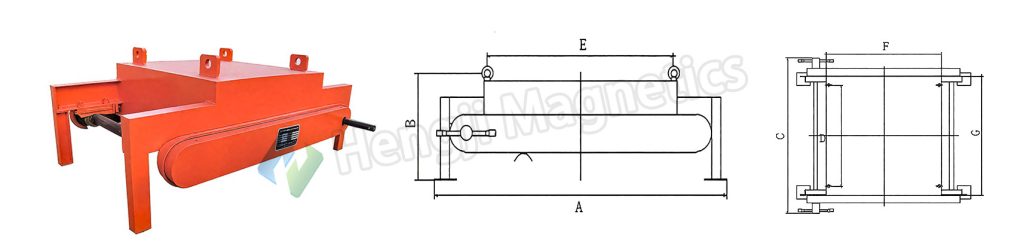

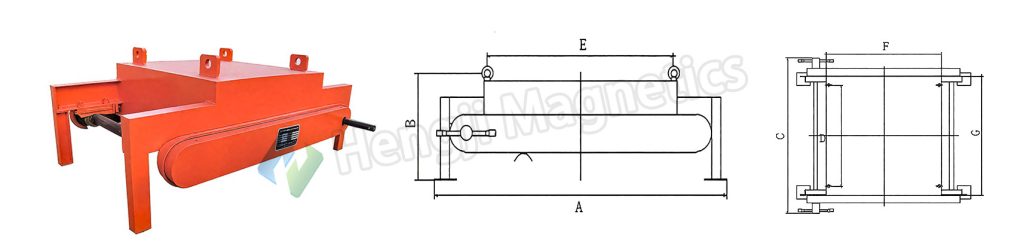

RCYP Neodymium Permanent Magnet Separator For Belt Conveyor Product Overview

The RCYP series manual self-cleaning permanent magnetic separator provides an efficient solution for extracting ferrous contaminants from non-magnetic materials. This robust neodymium magnet separator utilizes high-strength permanent magnets to deliver powerful magnetic performance without electrical power consumption, offering significant energy savings.

Designed as a versatile permanent magnet for belt conveyor systems, the equipment integrates seamlessly with various conveyor types. Its optimized structure and manual cleaning mechanism ensure reliable, long-term performance in demanding environments. This neodymium magnet separator effectively addresses the need for energy-efficient separation while maintaining low operational costs and minimal maintenance requirements across multiple industrial applications.

RCYP Neodymium Permanent Magnet Separator For Belt Conveyor Key Features

High-Efficiency Magnetic System

This advanced neodymium magnet separator generates powerful magnetic fields ranging from 900-1500GS. The optimized magnetic circuit ensures deep penetration, making this permanent magnet for belt conveyor systems highly effective at extracting deeply buried ferrous contaminants from material flows with consistent performance.

Manual Cleaning Mechanism

Featuring an X-shaped scraper chain sprocket transmission, this neodymium magnet separator requires minimal operating torque. The ergonomic drive arm and smooth reciprocating motion ensure complete contaminant removal, maintaining the permanent magnet for belt conveyor‘s reliability through user-friendly cleaning procedures.

Durable Construction

Engineered for harsh environments, this robust permanent magnet for belt conveyor applications incorporates wear-resistant components and high protection ratings. The neodymium magnet separator‘s optimized structure withstands demanding conditions while ensuring long-term operational stability and minimal maintenance requirements.

Eco-Friendly Operation

With zero energy consumption and silent performance, this permanent magnet for belt conveyor system offers environmentally conscious operation. The neodymium magnet separator complies with international standards while significantly reducing operational costs through its efficient, maintenance-free design.

RCYP Neodymium Permanent Magnet Separator For Belt Conveyor Working Principle

The RCYP neodymium magnet separator operates through an efficient combination of permanent magnetic attraction and manual mechanical cleaning, providing reliable ferrous separation without electrical power requirements for permanent magnet for belt conveyor applications.

Magnetic Attraction Phase

The permanent magnetic system within this neodymium magnet separator generates consistent, powerful magnetic fields that penetrate material layers to create effective separation zones. As materials transport beneath the unit, ferrous contaminants are extracted from the conveyed stream and securely held against the magnet surface. This fundamental process enables the permanent magnet for belt conveyor systems to provide continuous protection for downstream equipment.

Manual Cleaning Process

The cleaning cycle begins with manual rotation of the ergonomically designed drive handle, activating the X-shaped scraper chain sprocket system. This reliable mechanism initiates smooth reciprocating motion that efficiently displaces captured ferrous materials from the magnet surface. The neodymium magnet separator completes its cycle as contaminants fall into designated collection containers, restoring the permanent magnet for belt conveyor to optimal operating condition without requiring electrical power or complex maintenance procedures.

RCYP Neodymium Permanent Magnet Separator For Belt Conveyor Product Parameters

|

Model

|

Applicable Belt Width (mm)

|

Rated Lifting Height (mm)

|

Magnetic Field Intensity (mT)

|

Max. Material Thickness (≤mm)

|

Weight (kg)

|

Suspension Dimension (D×E, mm)

|

Overall Dimension (A×C×B, mm)

|

Magnetic Pole Dimension (F×G, mm)

|

|

RCYP-4

|

400

|

125

|

70

|

70

|

250

|

470×340

|

1100×910×500

|

500×500

|

|

RCYP-5

|

500

|

150

|

70

|

90

|

580

|

570×440

|

1200×1020×550

|

600×600

|

|

RCYP-6

|

600

|

175

|

70

|

125

|

680

|

670×500

|

1300×1120×560

|

700×700

|

|

RCYP-6.5

|

650

|

200

|

70

|

150

|

820

|

715×550

|

1380×1170×550

|

750×750

|

|

RCYP-8

|

800

|

250

|

70

|

200

|

1500

|

915×750

|

1630×1300×560

|

950×950

|

|

RCYP-10

|

1000

|

300

|

70

|

250

|

2300

|

1050×900

|

1765×1500×560

|

1100×1100

|

|

RCYP-12

|

1200

|

350

|

70

|

300

|

3300

|

1250×1140

|

1960×1750×580

|

1300×1340

|

|

RCYP-14

|

1400

|

400

|

70

|

350

|

3800

|

1450×1350

|

2180×1950×620

|

1500×1550

|

RCYP Neodymium Permanent Magnet Separator For Belt Conveyor Applications

Conveyor System Integration

The neodymium magnet separator provides essential protection at head and intermediate pulley positions on belt conveyors. This versatile permanent magnet for belt conveyor systems also integrates with vibrating conveyors and feeder systems, delivering comprehensive contamination control across various conveyance methods.

Industrial Applications

Power generation facilities utilize the neodymium magnet separator in coal handling operations, while mining operations employ this permanent magnet for belt conveyor applications for ore processing. The equipment serves metallurgical pre-treatment, building materials purification, chemical processing, and food production, demonstrating exceptional versatility across multiple industrial sectors.

Suitable Operating Conditions

This neodymium magnet separator excels in medium to small capacity processing environments, particularly where electrical supply is limited or unavailable. The permanent magnet for belt conveyor system is ideal for operations prioritizing energy conservation and space-constrained installations, offering reliable performance without power requirements while maintaining high separation efficiency in compact configurations.

RCYP Neodymium Permanent Magnet Separator For Belt Conveyor Services

Technical Guidance

We provide comprehensive product selection consultation for the neodymium magnet separator, including installation position optimization and performance analysis. Our experts evaluate your specific requirements to ensure the permanent magnet for belt conveyor system delivers optimal results in your application environment.

Installation Support

Detailed installation and operation manuals guide proper setup of your neodymium magnet separator. We offer on-site installation assistance and commissioning demonstrations to ensure your permanent magnet for belt conveyor operates at peak efficiency from initial startup through long-term operation.

Operation Training

Our training programs cover equipment principles and structural overview of both the neodymium magnet separator and permanent magnet for belt conveyor systems. We demonstrate proper operation techniques and emphasize critical safety procedures to ensure efficient and secure equipment operation.

After-Sales Support

We provide comprehensive quality guarantees for your neodymium magnet separator and dedicated technical hotline services. Our team ensures prompt resolution of any operational issues with your permanent magnet for belt conveyor, maintaining continuous productivity and customer satisfaction throughout the equipment lifecycle.

Categories

Categories