CTQ Rare Earth Roller Magnetic Separator Product Overview

The CTQ Series is a super strong magnetic dry powder separator. This advanced roller magnetic separator extracts ferrous contaminants efficiently.

It utilizes high-performance NdFeB permanent magnets. This rare earth roll magnetic separator ensures strong magnetic force and reliable, automatic operation.

It serves abrasives, refractories, and non-metallic minerals. This roller magnetic separator is also used in carbon black and food processing.

Its compact design is ideal for space-constrained environments. This energy-efficient rare earth roll magnetic separator offers significant advantages.

Through computer-optimized magnetic circuits, this roller magnetic separator sets new standards for processing efficiency. It maintains minimal operational costs.

CTQ Rare Earth Roller Magnetic Separator Key Features

Exceptional Magnetic Performance

-

This advanced roller magnetic separator utilizes high-performance NdFeB magnets.

-

It delivers a powerful magnetic strength exceeding 3000 Gauss.

-

The system features a computer-optimized magnetic circuit for efficiency.

-

Its progressive multi-stage separation design enhances performance.

-

These features make this rare earth roll magnetic separator highly efficient.

-

It is ideal for a wide variety of dry powder separation applications.

Intelligent Speed Regulation

-

The equipment features an MB series stepless speed regulation system.

-

It offers a wide operational speed range from 40 to 200 RPM.

-

This allows the roller magnetic separator to enable precise parameter adjustment.

-

Frequency conversion control provides fine-tuned speed management.

-

This feature allows the rare earth roll magnetic separator to adapt effectively.

-

It can be optimized for different material characteristics and final purity requirements.

Advanced Feeding System

-

The system incorporates an elastic vibration support structure.

-

This structure ensures an extended service life for the roller magnetic separator.

-

It is specifically designed to prevent harmful mechanical resonance.

-

An efficient material distribution system ensures even feeding.

-

This design makes the rare earth roll magnetic separator highly suitable.

-

It can handle various particle sizes and different material flow characteristics.

Robust Construction & Safety

-

The drum features durable stainless steel surfaces.

-

The entire roller magnetic separator is built with a heavy-duty construction.

-

This guarantees reliable, trouble-free operation in industrial settings.

-

The system employs a maintenance-free design for ease of use.

-

Comprehensive safety features are integrated throughout.

-

These qualities make the rare earth roll magnetic separator ideal for continuous use.

-

The equipment also meets all relevant environmental and operational standards.

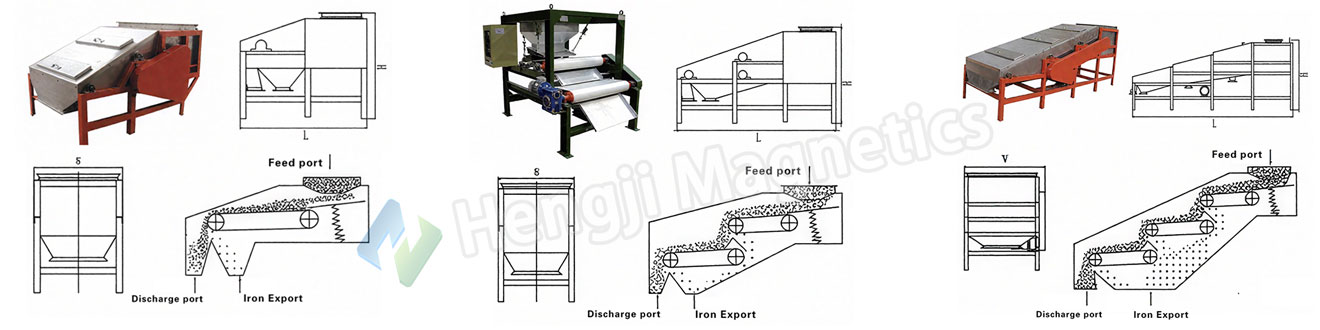

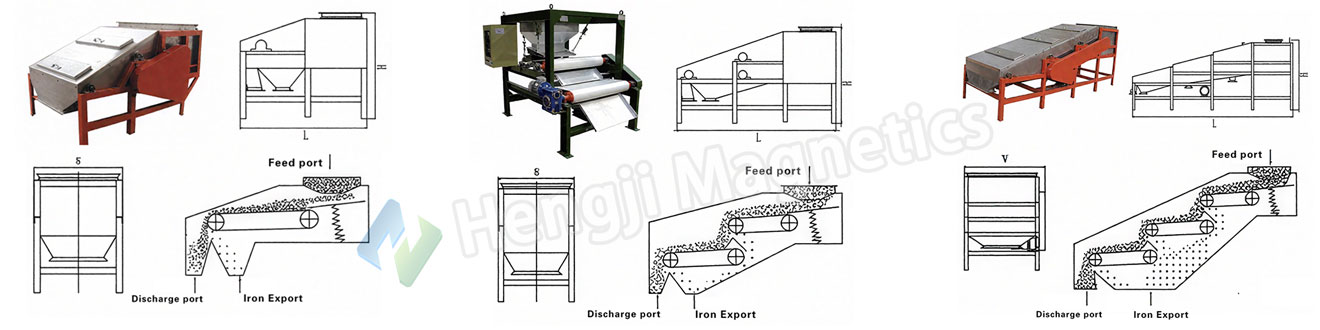

CTQ Rare Earth Roller Magnetic Separator Working Principle

Working Principle Overview

-

The CTQ rare earth roll magnetic separator operates through magnetic differential separation.

-

Materials are first uniformly distributed via a vibratory feeder.

-

They are fed onto a conveyor belt driven by the rear active roll.

-

This entire process is coordinated within the advanced roller magnetic separator system.

Magnetic Separation Process

-

As materials transport forward to the front magnetic roll area, ferrous contaminants are extracted.

-

They are firmly adhered to the powerful magnetic surface of the rare earth roll magnetic separator.

-

The continuous rotation of the magnetic roll carries the captured materials.

-

They are moved to the rear lower section of the machine.

-

There, specialized discharge scrapers effectively remove them from the magnetic zone.

-

This is a key function of the efficient roller magnetic separator.

Material Discharge Mechanism

-

Once the materials are separated from the active magnetic field, they lose magnetic attraction.

-

They then fall naturally through the discharge outlet via gravitational force.

-

This discharge occurs in the rare earth roll magnetic separator.

-

Meanwhile, non-magnetic materials continue their original trajectory unaffected.

-

They proceed directly to subsequent processing stages.

-

This achieves clean, effective separation in the reliable roller magnetic separator.

Operational Efficiency

-

This systematic working principle makes the CTQ rare earth roll magnetic separator highly effective.

-

It is particularly suited for dry powder separation applications.

-

The process is designed to ensure maximum final product purity.

-

It also delivers high operational efficiency and throughput.

-

These benefits are inherent to the advanced roller magnetic separator system design.

CTQ Rare Earth Roller Magnetic Separator Product Parameters

CTQ Rare Earth Roller Magnetic Separator Applications

Primary Industry Applications

-

The CTQ roller magnetic separator provides essential iron removal.

-

It is critical in the abrasives industry for processing alumina and silicon carbide.

-

This versatile rare earth roll magnetic separator enhances product purity in refractory materials.

-

It effectively purifies key non-metallic minerals, including quartz and feldspar.

-

The equipment plays a vital role in ensuring food safety during grain processing.

-

It improves the quality of animal feed.

-

It also purifies a wide range of chemical raw materials across multiple industrial sectors.

Applicable Material Characteristics

-

This efficient roller magnetic separator handles continuous iron removal.

-

It is designed specifically for dry powdered materials.

-

The system has a broad tolerance for varying particle sizes.

-

The rare earth roll magnetic separator adapts to different magnetic contaminant concentrations.

-

It can handle materials with varying flow characteristics (e.g., free-flowing, cohesive).

-

It maintains consistent, high-performance separation across diverse operating conditions.

Process Configuration Solutions

-

The system offers flexible installation options: single-unit operation or multi-unit series connections.

-

This roller magnetic separator integrates seamlessly with upstream and downstream equipment.

-

This includes conveying systems and automated packaging lines.

-

The rare earth roll magnetic separator can adapt to various production capacity requirements.

-

It is designed to fit within different plant layout constraints.

-

The system offers fully customizable processing parameters.

-

This allows it to meet the specific and precise production needs of different applications.

CTQ Rare Earth Roller Magnetic Separator Services

Professional Installation Guidance

-

We provide detailed installation manuals and on-site professional guidance.

-

This support ensures the proper level installation of the roller magnetic separator.

-

It also guarantees reliable electrical grounding for safety.

-

Our technicians assist with critical alignment steps, including drum rotation.

-

We deliver comprehensive setup services to ensure the optimal performance of your rare earth roll magnetic separator.

Operation Training

-

We deliver complete, hands-on training covering the entire startup sequence.

-

Training includes making all necessary operational adjustments for the roller magnetic separator.

-

We provide expert guidance on key parameters like feed regulation and speed adjustment.

-

Training also covers proper belt tracking and alignment.

-

The program incorporates essential safety procedures and industry best practices.

-

This ensures the proficient operation of your rare earth roll magnetic separator.

Maintenance Support

-

Our comprehensive maintenance programs include detailed wear parts identification.

-

We provide clear schedules for mandatory inspections of the roller magnetic separator.

-

We help establish and maintain detailed maintenance records for your equipment.

-

Our service includes providing proven troubleshooting guidance.

-

This support is dedicated to maintaining your rare earth roll magnetic separator system in peak condition.

After-Sales Service

-

Our extensive national service network provides prompt technical support.

-

This support is readily available for your roller magnetic separator.

-

We guarantee the supply of 100% genuine spare parts for all components.

-

We offer continuous technical support and operational consultation.

-

This lifelong service commitment supports your rare earth roll magnetic separator throughout its entire operational lifecycle.

Categories

Categories